Today, the most unpretentious and demanded heating devices in steam rooms are electric heaters for saunas (baths). They are more functional, easy to install and operate, do not require fuel and do not pose a risk of smoke. Manufacturers necessarily test products and sell them with a factory warranty up to 5 years.

Read in the article

- 1 Applications for electric ovens

- 2 Description of electric furnaces

- 2.1 Typical varieties

- 2.2 Device and principle of operation

- 3 Advantages and disadvantages

- 4 What to look for when choosing an electric oven

- 4.1 Calculation of the required power of the electric furnace

- 4.2 Materials of manufacture and volume of stones

- 5 Installation methods and rules

- 6 Features of operation

- 6.1 Safety engineering

Applications for electric ovens

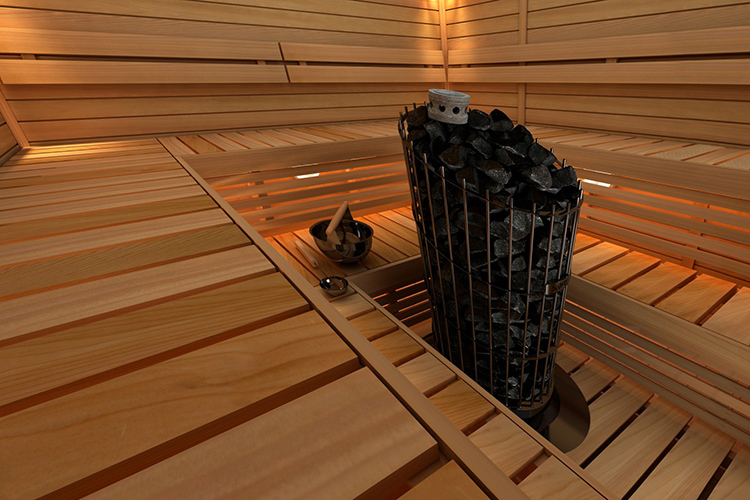

The modern version of the home bath is a small room, paneled with wood, with a sunbed and a heating device. Such a room can be equipped in any suitable place in a private house and city apartment. A sauna with an electric heater will easily fit into a closet, a balcony or even a bedroom. And how to choose the right stove for her - in this review from HouseChief.

On more spacious areas of private households, such equipment allows you to save time and money on buying firewood, coal or wiring an additional branch of the gas main. In any case, an electric sauna is the best solution.

Description of electric furnaces

Trading networks present a wide range of specialized electrical appliances of various capacities and the most intricate designs. It is not difficult for any lover of bath procedures to choose a model to their liking, focusing on their budget and room area.

Typical varieties

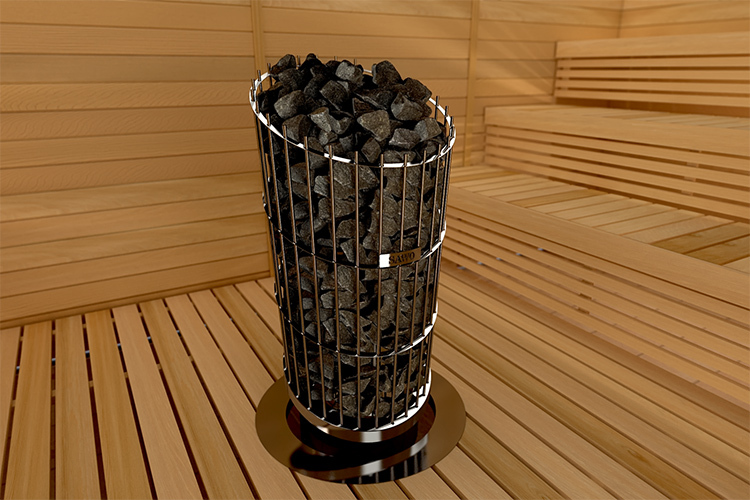

Electric furnaces with a large stone-laying mass (up to 60-80 kg). Such models take longer to heat up, but the resulting heat is soft and evenly distributed. Appliances can often be watered with water - it will evaporate without reaching the heating elements.

The stoves also operate in dry “sauna” mode. For work, you need an electrical network with a voltage of 380 V.

Heaters with a small amount of stones (20 kg). They provide quick warming up of the steam room, but are not recommended for frequent and abundant watering.

They are even installed in apartments. They work from a conventional 220 V.

Electric oven-thermoses. They have a closed body with a removable lid that covers the heated stones.

Such a "thermos" quickly warms up the room and makes the air as dry as possible.

Electric heaters with a steam generator. The ovens are equipped with a separate water tank, which contributes to the formation of a high humidity atmosphere.

They are not very popular due to the formation of air that is difficult to breathe.

Steam generators. Separate appliances for creating humid air in the steam room.

Often, an electric furnace is used in conjunction with a steam generator to get good dry steam. To do this, the appliance is installed at the base of the heater and steam saturated with moisture is driven through the hot stones.

Device and principle of operation

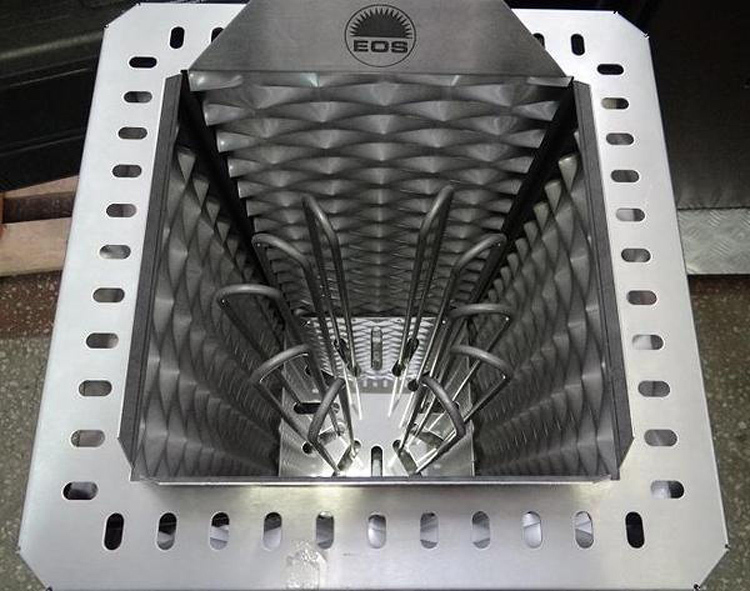

The basis of the design of an electric sauna stove is not complicated and consists of the following elements:

- open or closed metal case;

- stands for stones;

- heat insulating materials - double steel screens;

- electric heating elements - mainly heating elements or tape or combined heaters.

Stones of various weights and shapes are intended for heating the steam room. Ventilation ducts between the stone mass ensure uniform heating and maximum heat transfer.

When connected to the network, the heating element of the device begins to heat up and transfer heat to the stones, from which there is a gradual increase in temperature in the steam room.

Advantages and disadvantages

Sauna electric heaters, unlike wood-burning or coal-fired stoves, allow you to heat the steam room in a shorter period of time. In addition, the furnaces have the following advantages:

- quick and easy installation of equipment;

- ease of use;

- high level of security;

- reliability and long service life;

- lack of carbon monoxide emissions.

Electric ovens, even at the minimum mode, maintain the desired temperature for a long time, evenly distributing heat throughout the steam room. Good thermal insulation does not allow the body to overheat, which prevents burns. Design features allow you to install the stove 5-10 cm from the wall.

The disadvantages include:

- high cost of electricity, which eliminates the potential for frequent and long-term use of the bath;

- the impossibility of installing a powerful heater (from 7 kW) in the residential sector due to the limitation of the current power in the standard electrical network.

Compared to wood or gas stoves, electric stoves may have a lower heat output.

What to look for when choosing an electric oven

When buying an electric heater, you need to immediately pay attention to the thermal insulation qualities. An air gap between the steel sheets of the case acts as an insulator.

This design improves operational safety by protecting against accidental burns. An important point is the quality of the control mechanism.

More expensive equipment is equipped with a mobile remote control.

The main selection criterion is the indicator of the voltage of the power grids. Devices for 380 V are distinguished by higher power (over 4 kW) and economy, but they require a three-phase connection.

Calculation of the required power of the electric furnace

The required power of the equipment is calculated quite simply: for 1 m³, an average of 1 kW is required. These indicators are true for steam rooms with high-quality insulation of wall, ceiling and floor ceilings.

In the presence of a window, glass door, even with good thermal insulation for 1 m³, a coefficient of 1.2-1.5 is taken. For heaters with tape heaters, the heating volume can be increased up to 1.5 m³ per 1 kW.

Important! In apartment buildings, the use of electrical appliances with a power of more than 6 kW is prohibited.

Materials of manufacture and volume of stones

In the manufacture of the body of electric furnaces are used:

- stainless steel - one of the most popular materials, durable, with good heat transfer;

- enamelled steel is a relatively cheap option, but not very popular;

- cast iron is a reliable material that retains heat well, but is very heavy.

When choosing an electric heater, it is worth considering the volume of the cage and the mass of stones required. It is on the stones that the heat and the formation of steam depend.

It is recommended to use special stones that have been tested at high temperatures. The use of ordinary pieces of rock reduces the efficiency of the furnace and can be hazardous to health.

Installation methods and rules

This equipment is rarely installed in the center of a sauna. Most often it is located in the corner. During installation, a mandatory distance is left (its value is written in the oven passport) to the walls and thermal shields are attached to them.

Often they are sheathed on top with clapboard. The use of asbestos or gypsum boards is strictly prohibited. High humidity contributes to the rapid destruction of these materials. The floor under the stove should also be made non-flammable.

Exceptions are pendant models with low power.

Some units are even suspended from the ceiling.

When installing powerful equipment (more than 4-5 kW), a separate three-phase cable of a large cross-section (5-8 mm) must be wired with the installation of automatic protection on the switchboard.

It is recommended to install and connect to the network strictly following the manufacturer's instructions.

Features of operation

Heating the steam room at maximum power values can last from 30 minutes to 2 hours, depending on the general qualities of the model and the requirements of the instructions. After reaching the desired temperature, it is recommended to reduce the indicators by 2 times. The steam room should not be heated to 100 ° C. An atmosphere that is too hot will not only dry out the skin, but will also cause pyrolysis of wood (release of gaseous elements harmful to health).

To ensure sufficient heat supply, it is important to place the stones correctly. Large cobblestones line the bottom of the kiln stand, gradually decreasing in size towards the top. Do not stack too tightly, as this may obstruct air circulation. The cage should be filled carefully, taking care not to damage the heating element.

Periodic cleaning of stones, removal of split-off small fractions is essential. This process improves heat transfer.

Safety engineering

When installing an electric heater in a sauna, you should take into account some safety requirements:

- To prevent fainting from lack of oxygen, a ventilation deflector should be installed at the bottom of the door to bring in fresh air. Natural air circulation will help to evenly distribute heat throughout the room.

- It is not recommended to add essential oils directly to hot stones. For these purposes, special compositions are used that do not fade and do not harm the stove and the health of bathers. You can ennoble the air with a healing aroma using a separate container with hot water and a drop of fragrant oil.

- It is forbidden to dry any fabric products over the stove, even when the device is turned off.

It is also recommended to provide the steam room and adjacent territory with technical fire safety devices. Learn more about installing the sauna heater in this short video:

Of course, an electric heater cannot replace the classic Russian bathhouse - a wood-burning stove. But when arranging a sauna in an urban setting of an apartment building, such equipment is simply irreplaceable. The main thing is to adhere to the rules and recommendations of the manufacturer. Then your steam room will become a wonderful place for relaxation and health improvement after working days.