The compact size of some models allow you to use them in all conditions

CONTENT

- 1 Design and operating principle - the necessary basic knowledge

- 2 Types desktop sharpening machines - characteristics and useful properties

- 3 Universal grinder

- 4 What to look for when choosing: the main technical characteristics

- 5 What a table grinder is better to buy in 2019: choose the best model in the Russian market

- 6 Is it worth it to purchase equipment for sharpening cutting tools

Design and operating principle - the necessary basic knowledge

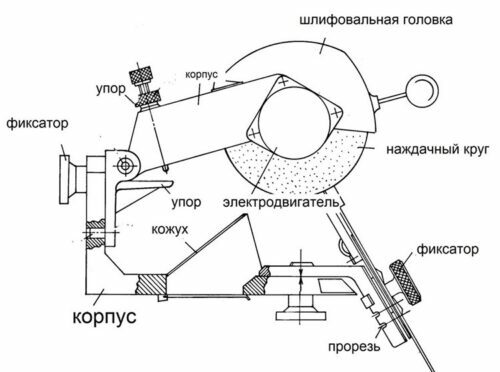

First of all let's see, what is a grinder in a constructive manner and how it works. Outwardly, this machine is a motor, hidden behind the steel casing, on both sides of which there are grinding wheels.

If certain technical skills you will be able to collect a similar machine yourself

In operation, the motor makes a rotational movement a certain speed, causing the abrasive elements to do the same. For sharpening you just need to bring cutting edges to sand a snap and hold the tool in the hands until the desired sharpness and smoothness of the metal is reached.

Before the operation, it is desirable to set the recommended sharpening angle rules - then treated the subject last much longer!

Always remember safety rules. Do not forget to use personal protective equipment during use of the grinding equipment (at least goggles and gloves). Avoid the presence of nearby flammable materials - sparks are formed in contact with the metal.

Types desktop sharpening machines - characteristics and useful properties

Despite the simple device and the operating principle, the hero of our review has its own classification. This is due to the abundance of cutting tools used in modern construction and industry.

Specialized grinder

This version only works with certain surfaces, but allows you to achieve better results in the treatment. Such equipment usually refers to professional equipment, rather than household - it affects both the range and in the price. Among the specialized grinders are several subtypes:

| Type of machine | Description |

| Sharpening machine with engraver | It allows to attach the metal or other material a certain shape and to apply inscriptions on their surface |

| Device for sharpening knives and scissors | It only works with these devices, they need to sharpen strictly at a certain angle with respect to the abrasion |

| The device for use with electric and gasoline chain saws | Used for the treatment of teeth of chain saws with different power supplies, also requires a certain skill |

| Grinding machine for drills | It makes it possible to return the old drills cutting properties of any diameter, is very popular in engineering |

Option for processing edges of knives and scissors - the most simple and affordable, but its functionality is not as wide

Universal grinder

Such a model is not difficult to understand from the name, it allows to carry out all the operations described in the preceding paragraph. At first glance, such a solution seems ideal. But the hefty "a spoonful of tar" makes the following factors: electric tool will be more prone to various breakdowns and outages. This is due to multitasking - such problems "sin", and other electrical and electronic devices. But you will be able to simultaneously perform both coarse and fine surface treatment.

With such an "animal" can be sharpened as the flat objects, and volumetric shapes

What to look for when choosing: the main technical characteristics

In any modern technology there are several critical parameters that directly affect their performance, durability and ease of use. Our "subject" was no exception. So now we look at the most important indicators, which must be followed under any circumstances.

Engine power

From this characteristic depends spindle rotation speed, which is fixed emery wheel. As a result, you will be able to sharpen, even from high-strength steel products. For the household is enough power in the 500-800 watts, but if planned a lot of work - it is necessary to consider professional options.

"Ordinary" model for everyday use powered by a standard 220V mains

The rotational speed of the abrasive wheel

Think in this case, too, it is clear - the more revolutions performs grindstone, the firmer the material can be processed. But at the same high speeds and require greater durability of all design elements, and the huge cost of electricity.

For domestic situations enough speed to 1000 rpm, and more powerful values may be required for complex processing

TONOTICE! (Click to see)

Since the metal contact with the abrasive at high speeds creates a spark, our editorial staff recommends choose machines equipped with special protective glass - it additionally protect your skin and eyes from possible injury.

The dimensions and the material used grinding stones

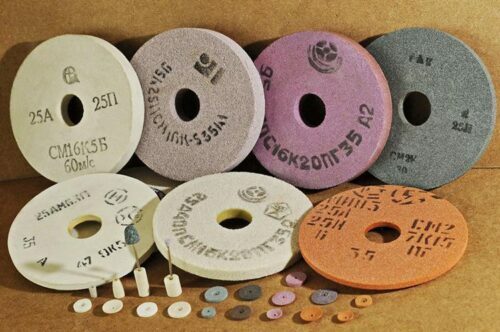

Emery is a consumable item, but that does not stop him from being one of the most important pieces of equipment. With regard to the working diameter of the circle, everything is simple - for standard, non-demanding machines it is 150 mm, for professional equipment -. Varies depending on the complexity and volume of work. The wizard also does not forget about the bore diameter - it determines the range of abrasives which you can use with the purchased model.

The marking, placed on the disk, referred to as dimensions and hardness, grain

Among the abrasives used in the production of materials the most popular are the following options:

| View | Scope | Appearance |

| electrocorundum | Sharpening carbon steels | |

| Monokorund | Working with high alloy | |

| Carborundum (silicon carbide) | It can handle articles of iron and non-metallic materials | |

| Diamond grit | Processing of heavy-duty metal |

TONOTICE! (Click to see)

Also, an important role can play this option as a structural density. Discs with an index equal to 5-8 have a higher density and are suitable for high-grade sharpening. If the value is 9-16, you can make only minor "cosmetic" procedures.

machine weight

Many buyers, choosing modern sharpening equipment which does not pay tribute to such a significant characteristic of the weight of the product. And although at first glance it is insignificant, you will experience all the "weight" of its importance when the encounter with the time consuming and bulky instruments. The fact that such situations can only handle assembly having sufficient weight - lightweight and compact solutions simply will fail. On the other hand, if you will only sharpen knives, axes or compact clippers - heavy construction will only be a burden.

Compact solutions suitable for apartment owners - they are easy to store and they do not tend to consume a lot of electricity

What a table grinder is better to buy in 2019: choose the best model in the Russian market

The time has come to move from theory to actually existing models of equipment, which is ready to effectively implement the functionality we considered above. So, drum roll! Meet the ranking of the best sharpening machines as of 2019.

Universal grinder Patriot BG150L

And here is the classic version, which at a certain skill you can use for grinding virtually any type of tool. Asynchronous motor design allows the owner to rid of unnecessary noise, giving an impressive performance. The presence of the protective glass and the lamp will maintain the health of the master and improve accuracy. And the presence of the two grinding wheels give the opportunity to do several treatments.

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 150 | 2950 | 150 | 4,3 |

Evaluation Tehno.guru edition: 9,2/10

Accessories universal DWT DS-150 KS

Better and faster results can offer this product. It may not boast the presence of the lamp, but it is very reliable in operation and does not require specialized skills.

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 150 | 2950 | 125 | 5,2 |

Evaluation Tehno.guru edition: 9,4/10

Universal grinding machine Ryobi RBGL650G

At the top of our ranking placed quality machine with a wide arsenal of features. The most useful is the presence of sanding belt - it would maximize your chances and make the process interesting and burdensome. The clear winner!

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 250 | 2850 | 150 | 10,3 |

Evaluation Tehno.guru edition: 9,8/10

Bench for sharpening chain saws and electric Sturm BG60016

Apparatus for processing links of chain saws are quite specific and not so popular as universal availability. However, we have chosen a nominee can make life easier and save you a large sum for the purchase of new parts to replace blunted. It is distinguished by the impressive specifications, incongruous with reasonable price.

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 160 | 3000 | 100 | 2,5 |

Evaluation Tehno.guru edition: 8,8/10

Grinding machine for drills Diold MZS-03

This practical and easy budgetary unit is designed to work with drills and knives. In addition to democratic prices it is characterized by a structure close to universal, as well as the presence of a rather wide nozzle assembly.

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 100 | 6700 | 48 | 1,1 |

Evaluation Tehno.guru edition: 8,4/10

Electric grinder for knives Sorokin 20.100

But the candidate has solid - in the presence of the electric motor, and a decent performance indicators. Such a proposal is suitable for small workshop or other entry-level private business.

| Power, W. | emery rotational speed, rev / min | The diameter of the grinding wheel in mm. | Weight, kg. |

| 70 | 140 | 118 | 4,3 |

Evaluation Tehno.guru edition: 8,3/10

Bench for sharpening knives and scissors Ganzo Touch Pro

And first on our list comes highly specialized equipment for household cutlery. It can not boast the presence of electrical components or high performance. But this is easily offset by the high accuracy of the work undertaken, affordable price tag and the possibility for a few minutes to return the sharpness to any scissors or knives. And the presence of bundled multiple abrasive stones allow the use of different options for sharpening.

Evaluation Tehno.guru edition: 8,1 / 10

Is it worth it to purchase equipment for sharpening cutting tools

Summing up the results of our small study, we can safely say that the grinding machines will be more relevant than a decade. You can, of course, simply replace the failed equipment and supplies, but much more practical and useful to make efficient use of available resources. So if you are fond of technology, working with cars or simply working knife thrower - you have to have to be at least an easy grinding machine!