Not every battery is suitable for installation in apartment buildings, because frequent pressure surges in the system and the use of water as coolant radiators affect performance. Some metals in contact with water and subjected to air oxidation and corrosion. It is a proven cast iron radiator.

Content:

- Characteristics of cast iron radiators

- Types of cast iron radiators

- Disadvantages of cast iron radiators

- Calculation of sections of cast iron radiators

- Mounting

Characteristics of cast iron radiators

- The material used is resistant to corrosion.

- Due to the resistance of cast iron to physical influences, a battery used with any kind of coolant. Its maximum temperature can be 150 degrees. A distinctive feature is the resistance to oxidation because iron does not react in contact with water, even if the acid-alkaline balance reaches a mark of 9-10 Ph.

- Perfectly accumulates heat, which increases its heat transfer when compared with other materials. Cast-iron batteries retain heat for a long time after switching off the supply of coolant.

- Durability heating appliances up to 30 years. With proper installation and care, air conditioning equipment live longer than the allotted time.

- The thick walls - the reason the cast iron radiators live a long life.

- The number of sections can be varied to achieve the desired heat level.

- If one section is damaged, only replace it, rather than the entire battery.

modern heating appliances design is different from the usual old "bellows", which are in some apartments. Popular device by using the art of casting, made in retrostile.

Suitable for three types of connection.

- Lower. With such connecting pipes are connected to the lower outputs from two sides. bottom connection minus - a small circulation.

- Side.Such a connection method provides maximum circulating coolant, as a pipe connected to the outer section into lower and upper side outputs audio.

- Upper.Pipes are connected to the outputs of the upper end sections. Circulation in this connection is much higher than at the bottom.

Cast iron radiators are molded from a homogeneous mass of the alloy intended for use in heating systems of houses. Section are manufactured separately and connected using engineered seals and sealing nipples.

The stated in the specifications heater power is almost always different from the actual. This is due to the conduct of the radiator test under laboratory conditions, which differ from the real.

The heated coolant flows through the pipes in the heating system the radiator compartment and heats the indoor air, giving up heat.

Types of cast iron radiators

- Single channel. In this type of design radiators channel is present in each section, which circulates the heat transfer fluid. Climatic device of this kind is easy to wash, so they are placed in medical institutions.

- Two-channel. One section of this type of heating devices present channel 2, which improves heat transfer.

- Three-channel. Indicators on heat transfer is higher than with other types, with their weight, and the depth is much greater than that of peers.

In two- and three-channel heating radiators used ribbing that enhances the heat transfer. Section are styled in different styles, from retro to futuristic. Sometimes use a metal casing that hides the battery.

Popular Dual radiators, because they are compact and have good heat dissipation.

Cast iron radiators are divided by setting method:

- Wall. Mounted on the wall with reinforced brackets, this type of fastening - classic.

- Floor. Batteries are supplied with four legs. They are parts of the end sections, so they are difficult to break off. These do not require additional fasteners, which will keep the wall. In addition, not all the walls stand iron. Behind them easier to clean, as the distance from the wall can be much greater than that of the classic types of fasteners.

In height, average size ranging from 35 to 150 cm. The length depends only on your preferences, because the number of sections can be different, and the width depends on the number of channels.

Disadvantages of cast iron radiators

- The weight. This is a major disadvantage for cast iron products, and radiators are no exception. Due to the weight, and not because of aesthetics, started production of the batteries in the "legs" because not every wall is capable of supporting themselves on considerable weight iron.

- Effect thermos. Attributed to the pluses and minuses. Cold radiators are heated for a long time. When you turn off the heating, cast iron, at the expense of the same properties over a long period of time remains warm and continues to give off heat.

- Hammering. Some models are cast iron radiators can not withstand pressure surges. Strokes occur in apartment buildings that are connected to the centralized heating system. This is solved by setting the pressure regulator.

- Pollution. Cast-iron batteries strongly gathering dust, and design is not always possible to make a full and qualitative cleaning.

- Appearance. Externally iron devices - attractive, but the beauty is worth to pay extra for. Products made of this metal are sold unpainted, so the appearance does not cause sympathy.

Outputs from this situation:

Yourself paint the battery. Colored battery can look unsightly, if unevenly apply layers of paint.

Set on the air conditioning grille. With metal covers can "hide" a battery from prying eyes, but these pads reduce heat transfer quality, and the room becomes cooler.

Order cast iron radiator, designed in the style of artistic tide. Battery, cast in a variety of styles, do not require painting. This radiator is not suitable for all interiors.

Calculation of sections of cast iron radiators

Before purchasing iron unit will require calculations that will more accurately determine the number of sections. The example uses the following data:

1. The amount of heat one section is 145 watts (the average is taken, accurate data is available in the data sheet product).

2. The calculation is made for a room with normal insulation, a street wall and one window. According to the SNP, the amount of heat which is required for its heating - 100 watts.

3. Size of the room - 4 x 3 meters.

Payment

1. Determined area of the room. It is 12 m2.

2. Multiplied by the area and the amount of heat needed for heating one square meter of space. By SNP, for example from room required 100 watts / m2. After performing this action turns 1200 watts.

3. The amount of heat required for the room should be divided into one part of the heat battery. After - round off the result obtained in a big way.

4. It obtains the number of sections required for installation. For rooms indicated in the example set radiator consisting of 9 sections.

The calculation is focused on space, the height of which does not exceed 3 meters.

Since each room is unique, there are factors that make it possible to more accurately make calculations:

For accurate measurement of the amount of heat per square meter, the height of the ceiling to be divided by a factor of 3. For a room with a ceiling of 2.5 m it will be 0.83.

For the calculations used coolant average temperature, which is 70 degrees. By increasing this parameter, a finite number necessary to subtract 15% every 10 degrees, the temperature is lowered - perform the opposite effect.

If the room is not one, but 2 or 3 wall street, it is necessary to multiply the amount of heat for 1 m2 by a factor of 1.75. After that, the number of sections to be divided by the number of windows, and install the radiator at each of them. This will ensure uniform heating in all rooms.

If the room has additional insulating layers, and also if double-glazed windows, the quantity of heat allowed to 1 m2 divided by 0.8.

For houses located in areas of extremely low temperatures, the amount of heat for 1 m2 increased by 2 times.

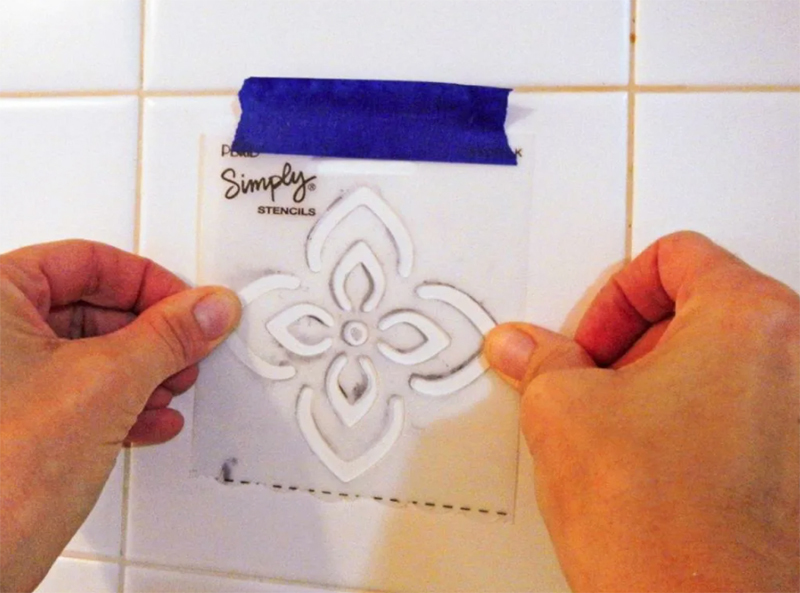

Mounting

Before installing cast iron radiator, you need to parse it into sections, check out fixing nipples, then assemble. Mount the need, given the weight of the battery and the wall material in the room. The minimum set of tools - Bulgarian, hammer, wrench, building level and die.

1. If the wall of brick or concrete, selected hardware, which is designed for the weight of the radiator with coolant. SNIP, it is recommended to use 3 or more brackets.

2. You can not hang a cast iron radiators on the walls of wood or drywallBecause they can not withstand the load. In this case, you can install the radiator on the floor stand or legs. Mounted on the wall it is only to maintain the upright.

After installing the radiator, made his connection to the central heating system using couplings and eviction. Threaded connections recommended to seal.

Cast iron radiators must be periodically tint paint that withstands the heating temperature without changing color.

Connection to the heating system:

1. diagonal. Used when connecting multiple-units. A delivery tube is connected at the top with one hand, and the reverse - the bottom on the other.

2. Lower. Used when the pipes are hidden in the floor of the room or behind baseboards. It is an aesthetic way to connect. Flow and return connections are located at the bottom.

3. lateral. A delivery tube is attached to the upper Threaded inverse - the bottom. Side connection has the greatest heat loss. In case of poor heating in multiple-heating devices, it is recommended to mount the Extension of coolant flow.

4. Consistent. Coolant moves under the pressure of the heating structure. To remove air used cranes Majewski. The drawback is the need to remove the battery, and when repairing a disconnected heaters.

5. Parallel. Connecting create through a conduit attached to the feed riser. Heat transfer fluid leaves the pipe is connected to the return pipe.