To form a flat surface, when preparing the base for decorative flooring, beacons are used to screed the floor. Their types and order of installation may differ significantly. It all depends on what type of base is preferred. We offer you to get acquainted with the most common ones, so that it is easier for you to make a choice.

Read in the article

- 1 Work performed before installing the beacons under the screed

- 1.1 Preparatory stage

- 1.2 Definition of zero level

- 2 Lighthouses for floor screed: types of materials used, installation with different installation methods

- 2.1 Dry floor screed

- 2.1.1 Beacon types

- 2.1.2 Installation rules

- 2.2 Semi-dry floor screed

- 2.2.1 Concrete

- 2.2.1.1 Beacon types

- 2.2.1.2 Installation sequence

- 2.2.2 Cement-sand

- 2.2.2.1 Beacon types

- 2.2.2.2 Installation rules

- 2.2.1 Concrete

- 2.3 Wet floor screed

- 2.3.1 Beacon types

- 2.3.2 Installation rules

- 2.4 Screed based on self-leveling compounds

- 2.4.1 Beacon types

- 2.4.2 Installation rules

- 2.1 Dry floor screed

Work performed before installing the beacons under the screed

Before proceeding with the installation of beacons under the screed, a whole range of preparatory measures should be performed. This will form a level and solid base that can withstand significant stress.

Preparatory stage

Before installing the beacons, thoroughly clean the floor surface from:

- accumulated debris, dirt and dust;

- topcoat;

- skirting boards and other plastic or wooden structures.

If there are irregularities on the cleaned base, they are smoothed out with a grinder or manually until a smooth horizontal surface is obtained. The presence of cracks, recesses even of a small size is unacceptable, since in the future they may cause the screed to crack. To seal the grooves, compounds with minimal shrinkage are used, which take a little time to set. If necessary, the grinding is repeated.

The prepared base is covered primer and waterproofing compound. A continuous layer will strengthen the structure and protect against excess moisture.

Definition of zero level

After preparing the base, find the zero point, proceeding in the following sequence:

- an initial point is set on the wall at a height of about 1.5 m, which will be used in further measurements;

- a base level is drawn through the marked point using the building level;

- the distance from the base level to the floor is measured. The maximum number of measurements is taken to ensure sufficient accuracy. As a result, the largest and the smallest distance should be found;

- add 3 cm to the smallest value. At the found distance, there will be the upper point of the tie;

- a line is drawn along the entire perimeter of the room through the point corresponding to the upper point of the tie. Lighthouses will be displayed along it.

Lighthouses for floor screed: types of materials used, installation with different installation methods

For the formation of an even screed, it is very important to ensure the reliability of fixation of each beacon. Displacement of landmarks under the influence of the poured solution or the poured mixture is unacceptable. We offer you to get acquainted with the main types of landmarks used in the construction of screeds and the method of their installation.

Dry floor screed

For the device of a dry screed use bulk materials and mixtures thereof. The most widespread is expanded clay, which is evenly distributed over the base. In order for the beacons to remain in place in the process of leveling the bulk material, they must have sufficient strength characteristics. After the screed is installed, the landmarks remain in place, and therefore their height must fully correspond to the thickness of the backfill.

Related article:

Pros and cons of dry floor screed, manufacturing technology, types by manufacturer, and how to choose and correctly calculate the required amount for work, laying technology, price review and user reviews.

Beacon types

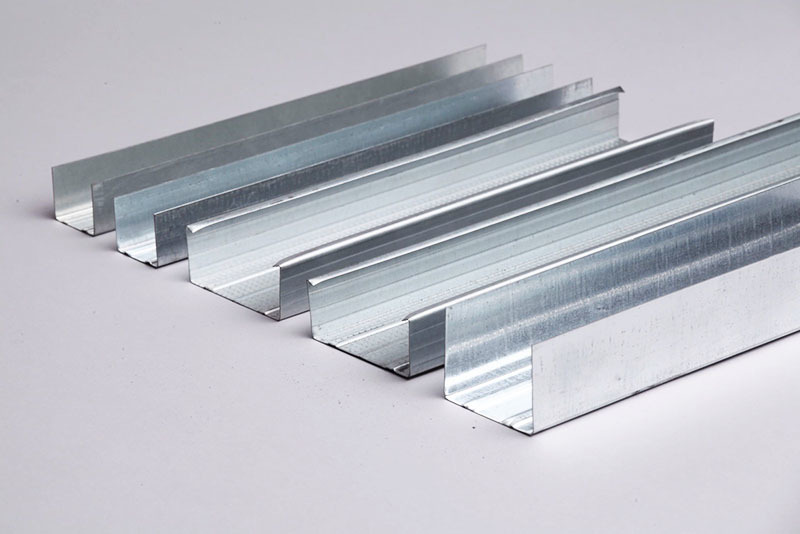

Metal profiles are most often used as beacons when arranging a dry screed. Their configuration does not really matter. However, they must be strong enough to support the weight of the bulk material. Otherwise, metal profiles can bend over time. As a result, the evenness of the screed will be compromised. U-shaped profiles are laid on the base with sharp edges up.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

“It is worth abandoning the use of point landmarks. They can lead to a leakage of the substrate. "

Alabaster can be used as guides, which requires a minimum of time to dry. In order to save money, some make a choice in favor of fittings, the remains of shaped pipes, rails, and a T-shaped profile. Such landmarks are retrieved after the completion of the work. In this case, you can only move along the screed along GVL sheets, the side of which is at least 0.5 m.

Installation rules

Installation of beacons is carried out using the following technology:

- the foundation is being prepared and the zero level is determined;

- a profile is mounted with a given step. Typically 1 m. The distance between the landmarks should be less than the length of the rule. The height of each element is controlled by a rule;

- expanded clay is poured and distributed over the surface.

Semi-dry floor screed

Accepts device on virtually any substrate. There are different types, depending on the materials used in the preparation of the mixture. A distinctive feature is the minimum amount of water used in the preparation of the solution. This speeds up the drying process and reduces the amount of dirt that forms.

Related article:

Semi-dry floor screed: specificity, performance characteristics, advantages and disadvantages, types of laying, calculation of the necessary the number of components, the optimal thickness of the formed layer, the technology of installation work manually.

Concrete

For the screed device in this case, concrete is used with a minimum amount of screed. The required level of plasticity is ensured by introducing a certain amount of additives. Various landmarks can be used to form a flat surface, each of which has its own characteristics.

Beacon types

Most often used:

- drywall profile. The dimensions are selected taking into account the thickness of the layer being formed. It is mounted on fixed supports, gradually leveling it in height. The profile is mounted on mortar, bars, brick;

- self-tapping profile. An effective method to quickly complete the installation of beacons.

Installation sequence

Installation of the profile on self-tapping screws is carried out in the following sequence:

| Illustration | Description of action |

| Dowels with self-tapping screws with a diameter of 6 mm are being prepared. The length of the screw depends on the height of the screed to be formed. Mounting holes are drilled at the location of the beacons |

| Dowels are first driven into the prepared holes, then the screws are screwed. The step between each element is selected from an interval of 20 - 30 cm |

| Focusing on the readings of the laser level, each screw is tightened to the required depth. At the same time, be sure to take into account the thickness of the plank, which will fit on top |

| They control the correctness of the work performed using a level. To do this, it is sequentially laid on screws, not only in one row, but also in neighboring |

| A profile is installed on top of the screws. Its spatial position is additionally controlled. Fixation of beacons is carried out using a solution |

Cement-sand

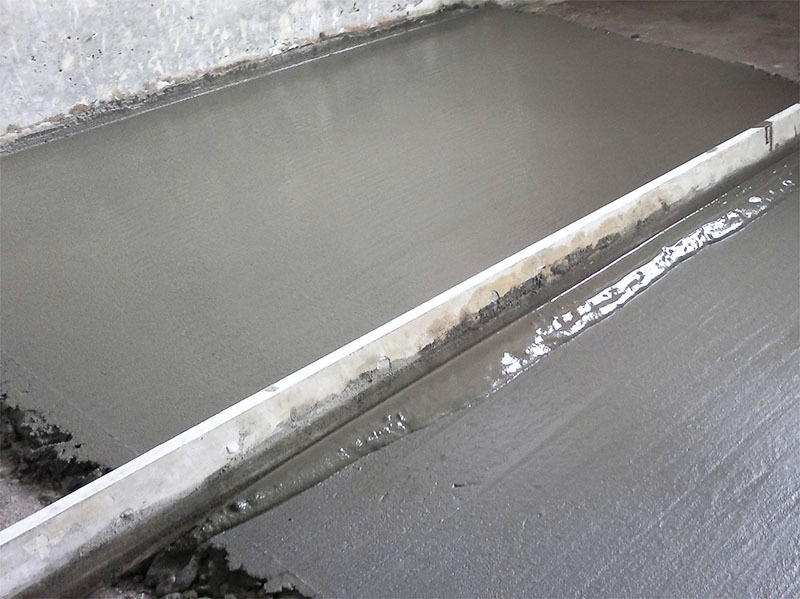

For the device of a cement-sand screed, a mixture is used that is diluted with water to the state of a suspension that sticks together into a lump, but does not release moisture at the moment of compression. Thanks to this, the mixture keeps its shape quite well. This imposes certain requirements on the beacons used when installing the screed. We offer you to get acquainted with the main varieties.

Beacon types

As reference points for the construction of a cement-sand screed, use:

- metal profile on screws;

- metal profile on concrete mix;

- concrete or lime mixture;

- combined options.

Installation rules

Regardless of the type of beacon chosen, the guide profiles are located perpendicular to the longest wall in the room. They are placed in 20 cm increments. The outer rows should be at a distance of 30 cm from the wall. Based on the information provided, before starting work, the required number of profiles is calculated.

The installation procedure for screed beacons may vary. The metal profile can be fastened with self-tapping screws. They are screwed into plastic dowels or a wooden cork at the base. At the same time, the spatial position of each guide is carefully controlled.

Instead of screws, concrete mortar is sometimes used. Work in this case is performed in the following sequence:

| Illustration | Description of action |

| The mixture is applied to the surface of the base. A solid and even material is laid on top: plywood or a piece of tiles |

| Using the rule of sufficient length, the concrete mix is leveled, becoming a reference point for future guides |

| The height of the prepared platform is controlled in the longitudinal and transverse directions. Then the beacons are left to dry completely. |

| Mortar is thrown parallel to the wall. Its amount should be sufficient to form a landmark of the required height. |

| Using the rule, the solution is leveled |

Sometimes the concrete solution is immediately brought under the rules. In this case, dowels with self-tapping screws are screwed along the stretched line. The mixture is poured onto the cord from above. A U-shaped profile, pressed into the solution, acts as a beacon.

Wet floor screed

For the device of a wet screed, concrete with an optimal moisture level is used. Taking this into account, increased requirements for strength characteristics are imposed on lighthouses. Landmarks must maintain their spatial position after pouring concrete. We invite you to get acquainted with the main types.

Beacon types

The main types are:

- metal profile, fixed with a solution or self-tapping screws. Its strength characteristics must be fully correlated with the applied load. In some cases, two or more profiles are laid at the same time;

- combined option. Assumes the simultaneous use of screws;

- wooden blocks;

- beacons from the solution.

Installation rules

The installation of screed beacons is carried out in compliance with the following rules:

- the process begins with marking the territory. On the surface of the floor, a line is drawn along which the device of beacons will be made;

- between the wall and the nearest landmark should not be less than 30 - 40 cm;

- concrete should only be poured onto a primed base.

If you have any more questions about how to install beacons, watch the following video:

Screed based on self-leveling compounds

Using self-leveling mixtures special requirements are imposed on the beacons used. The small thickness of the formed layer will not allow the use of high-thickness landmarks. We suggest that you familiarize yourself with the suitable types so that the installation is carried out correctly.

Related article:

Self-leveling floor mixes: what it is, features and types, advantages and disadvantages, leading manufacturers, popular formulations, procedure for calculation, selection and application with detailed instructions.

Beacon types

As a beacon for a screed based on a self-leveling mixture, it is worth using:

- benchmarks. Professional guides allow you to create the perfect surface. Elements in the form of a tripod, in which the central rod is made to move. Thanks to this, it is possible to set the desired level. After the screed is poured, the benchmarks are dismantled;

- self-tapping screws. This is a homemade analogue of benchmarks. Self-tapping screws are screwed into dowels, fastened with punched tape, and then the resulting structure is used as a level. After the layer has solidified, the screws are dismantled.

Installation rules

The installation procedure is practically the same as described earlier. However, in this case, it is necessary to fix each element as firmly as possible.

Watch the video to get a better understanding of the basic rules:

Share in the comments if you had to install beacons for the screed, which type you chose and why.