Drywall is a modern building and finishing material with which you can create or veneer structures of various configurations. Plasterboard sheets (GKL) allow you to quickly and easily align walls, ceilings and create light interior partitions, furniture and much more. Finishing houses, apartments, offices and other premises with this material is possible not only for experienced professionals, but also to an ordinary person who knows how to handle an instrument and has a desire to do everything with his own hands. HouseChief experts will tell you in this material that working with drywall with your own hands is not such a difficult task, and knowing some of the subtleties will help with self-finishing the premises.

Read in the article

- 1 How to work with drywall: key points

- 1.1 How to choose wall and ceiling material

- 1.1.1 Drywall device

- 1.1.2 Varieties of GKL

- 1.1.3 Material parameters

- 1.1.3.1 GKL thickness

- 1.1.3.2 Edge type

- 1.1.4 Sheet sizes

- 1.2 Cutting and cutting sheets

- 1.3 How to bend the GKL

- 1.4 Surface preparation

- 1.5 Markup design

- 1.6 Necessary tools and materials

- 1.1 How to choose wall and ceiling material

- 2 Fixing drywall sheets

- 2.1 metal profiles

- 2.2 wooden frame

- 2.3 Glue

- 2.4 Foam

- 3 Features of additional work during the installation of GKL

- 3.1 Insulation installation

- 3.2 Sound insulation pad

- 3.3 Bookmark electrical equipment

- 3.4 Finishing work

- 4 Errors when working with drywall

- 5 A few words at the end

How to work with drywall: key points

In order to independently build drywall structures and use it in the repair of premises, you need to familiarize yourself with some of the nuances. It is necessary to choose the right material, cut it, cut it and mount it. All this will be discussed below.

How to choose wall and ceiling material

To choose the right drywall, you need to know the most necessary information about it. You need to have an idea of how it works, its varieties, parameters, dimensions and type of edge.

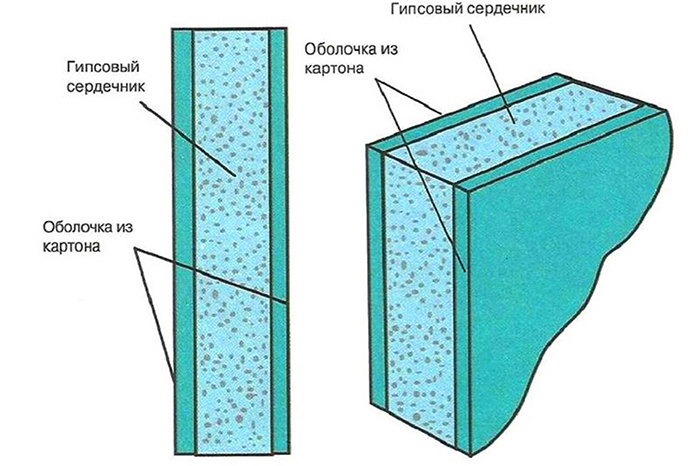

Drywall device

The structure of the GCR is very simple:

- gypsum core, to which various components are added that determine the type of sheet (regular, moisture resistant, refractory);

- special cardboard glued to the core on both sides. In fact, this is a drywall frame, which is also an ideal basis for applying finishing finishing materials (tiles, wallpaper, paint, etc.).

Varieties of GKL

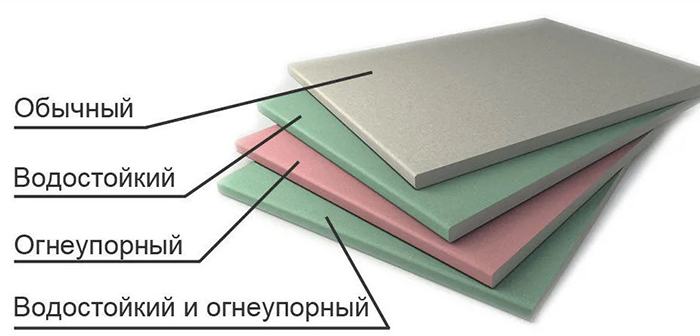

There are three main types of drywall sheets designed specifically for certain operating conditions. This is one of the most important parameters to consider when buying a material. So this is:

- Ordinary or standard (GKL). The most common type of drywall, which is used for finishing ceilings and walls in rooms with a normal microclimate and which do not have high requirements for moisture and fire resistance. The cardboard is painted gray and has a blue marking.

- Moisture resistant (GKLV). It is used for facing surfaces and creating various structures in rooms with high humidity (kitchen, bathroom, toilet, balcony, loggia). This variety contains hydrophobic and antifungal additives and is colored blue or green.

- Refractory or fire resistant (GKLO). The composition of the material includes special flame retardant and reinforcing additives that are resistant to high temperatures and even open flames. It is used in dry and damp rooms (ventilation shafts, attics, production shops, etc.). It is mostly red or pink in color, but there are gray sheets with red markings.

There is also a fourth variety - moisture- and fire-resistant drywall, characterized by high performance. It is used for rooms with high humidity and high temperature conditions (baths, drying chambers, etc.). The material has a green color with a red marking.

Material parameters

Drywall also differs in thickness and type of edge. These parameters need to be paid attention to, as they affect the final result of the finish.

GKL thickness

This parameter varies between 6–25 mm. Sheets with a thickness of 6 mm are very thin and are used to create arched and purely decorative structures, as well as multi-level ceilings.

Drywall with a thickness of 9.5 mm is most often used to create multi-level ceiling structures. The material is lightweight and durable. GKL 12.5 mm thick - the most common and are used for wall cladding and single-level ceilings.

Finishing material with a thickness of 14–24 mm is suitable for the construction of interior partitions. Due to this thickness, high-quality sound insulation, resistance to mechanical damage and stress are provided.

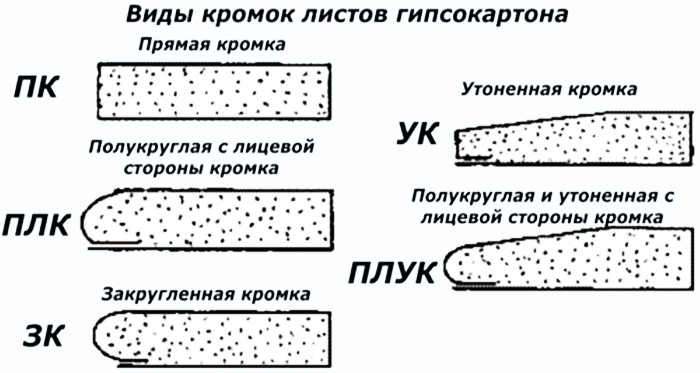

Edge type

Gypsum boards also differ in the type of edge:

- straight - the material is used in dry installation and does not require processing with putty, since the edges of the KGL are completely covered with cardboard;

- round;

- semicircular – seams can be sealed with putty with or without reinforcing tape;

- semicircular and thin - allows you to achieve perfectly even joining of sheets to each other;

- rounded – when filling joints, the use of reinforcing tape is not required;

- refined - reinforcement of the seams with a "serpyanka" is required, followed by puttying.

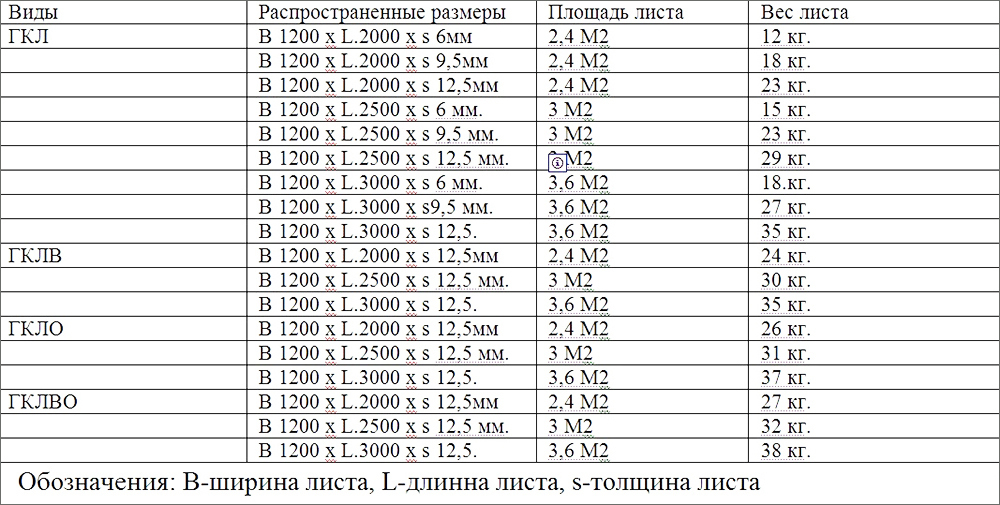

Sheet sizes

When choosing a material for wall or ceiling sheathing, an important factor is the size of the drywall. The width of the sheet, depending on the type and thickness, is 600–1200 mm, and the length varies between 2500–4000 mm. Therefore, when deciding what size to choose GKL, you need to take into account the area of the surface to be treated. Finishing work can be done faster if you use solid sheets. Fewer seams will save putty and make the surface more even.

Cutting and cutting sheets

Cutting and cutting drywall sheets is one of the important stages of finishing work that requires care, because an error in measurements or careless movement will lead to damage to the material. In addition to solid drywall slabs, it is often necessary to use rectangular and curvilinear plasterboard fragments of different sizes, as well as cut round and square holes for installation elements (junction boxes, spotlights, switches, sockets and etc.).

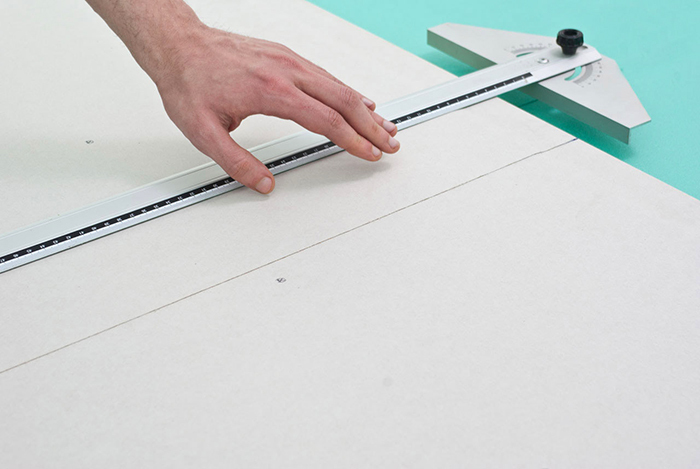

GKL cutting is recommended to be performed on a solid horizontal surface (you can do this on a stack of drywall sheets). The markup is applied to the front surface of the cardboard. With the help of a tape measure and a pencil, two maximally distant points are marked on the sheet. Then a flat and rigid metal bar is applied to the marks (ideally, a building rule).

Important! It is not recommended to use a short building level for cutting drywall, especially if its edges are rounded and have a galvanized profile.

The blade of the knife is pressed tightly against the rule and, with not very strong pressure, is carried from the initial to the final target point. Try to cut in one pass. The main thing is to cut through the top sheet of cardboard. By pressing with your hand on the part to be cut off, we break off a fragment of the sheet. It remains to cut through the paper from the back of the GKL. To facilitate cutting, a rail or beam can be placed under the cut.

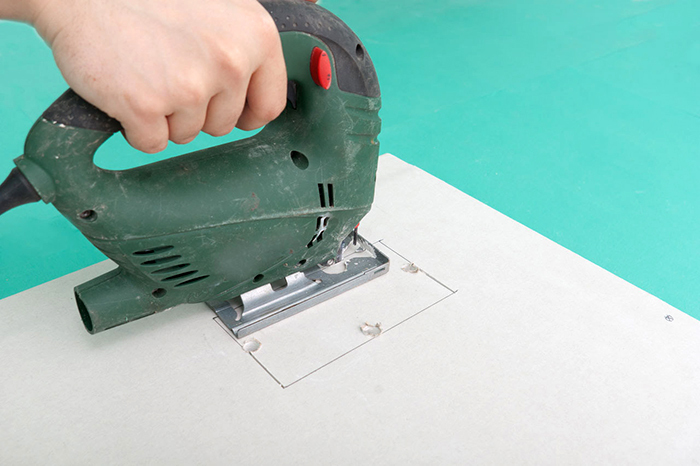

Cutting various holes is more complex than straight. To transfer the location of the fixtures to the sheet, we measure the distance from the attachment points of the GKL sheet to the center of the lighting fixture cartridge. Knowing the radius of the lamp without taking into account the cladding, we draw a circle with a compass and cut out the core with a knife, electric jigsaw or band cutter (crown) of the appropriate diameter. In the same way, the locations of switches, sockets, pipes and vents are measured and transferred to the sheet.

How to bend the GKL

Often there is a need to veneer curvilinear structures with drywall: arches, multi-level ceilings and decorative elements. The easiest option is to use a special arched drywall (GKLA), which has a thickness of 6.5 mm and is specially designed for this purpose. However, this variety is not cheap, so the craftsmen came up with several other ways to bend the GKL for curvilinear structures:

- Water or wet way. A drywall sheet is wetted with water on one side (using a paint roller or brush) and after absorbing moisture (5-10 minutes) it becomes softer and more flexible. The material is given the necessary bend using a special plywood or metal frame template. This method is used if the bending radius is small, since drywall will break at a large angle of curvature.

- Needle roller and water. With the help of a needle roller, a sheet of drywall is rolled on both sides, after which it is wetted with water. Moisture, penetrating into a large number of voids obtained, softens the gypsum layer, it becomes more pliable and easily bent. You need to bend the material carefully so that it does not break.

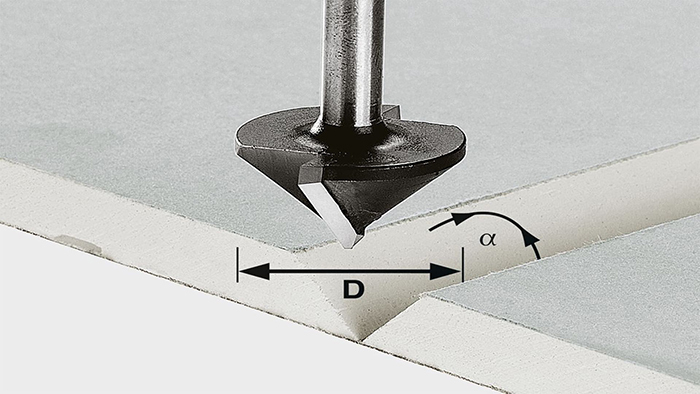

- Knife cuts along the fold line. Using a knife, shallow V-shaped cuts are made on the processed drywall perpendicular to the bend at a distance of 10–40 mm from each other. For the manufacture of convex bends, incisions are made on the front side of the sheet, and for concave - on the back. The advantage of this method lies in the fact that wetting the drywall with water is not required, and bending can occur with a smaller radius.

- Drywall cutter. The V-shaped cutter makes cuts almost to the entire depth of the GKL without damaging the second layer of cardboard. As with a knife, cuts are made perpendicular to the fold. The smaller the bend radius, the more often you need to make cuts.

Surface preparation

Before covering the walls and ceiling with drywall, it is necessary to prepare the surface. Seal all cracks to prevent further damage. Treat the surface of walls and ceilings with antibacterial and anti-corrosion compounds to prevent the appearance of rust, fungi and mold. In rooms with high humidity, a waterproofing device will be required, and for frameless installation, an additional primer must be applied to enhance adhesion.

Markup design

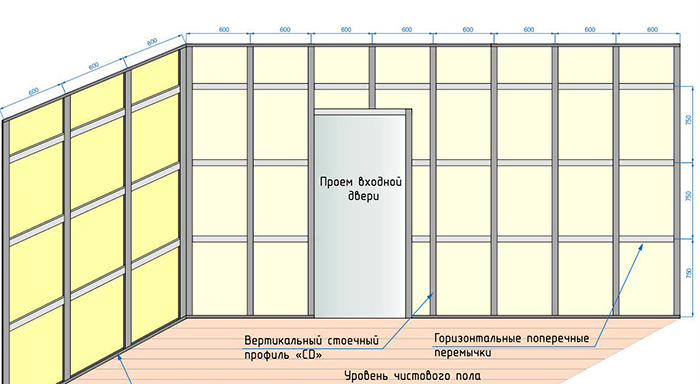

Marking is an important stage in the finishing work with drywall, since it depends on how smooth the surface will turn out. First of all, you need to decide on the thickness of the frame, the minimum thickness of which is 45 mm. This value can be increased if it is intended to fill the empty space with insulation or if the wall or ceiling surfaces are uneven.

On the wall, it is necessary to beat off the distance from the ceiling and, using a water or laser level, draw a line along the entire perimeter. Then beat off the lines indicating the vertical posts, between which you need to guard a step of 600 mm. Next, horizontal lines are drawn in increments of 500 mm. Hangers are installed at the intersections of the profiles.

Necessary tools and materials

To create drywall structures, you may need various tools and materials. The list of necessary depends on the method of installation of the GKL. So what do you need from the tools:

- perforator or impact drill;

- screwdriver;

- Sander;

- "Bulgarian" with cutting discs;

- metal scissors;

- hammer;

- a set of spatulas;

- peeling planer;

- laser or bubble building level;

- paint roller and brushes;

- clerical or linoleum knife;

- mixer nozzle;

- rule;

- square, plumb line, tape measure, ruler, pencil;

- container for diluting putty.

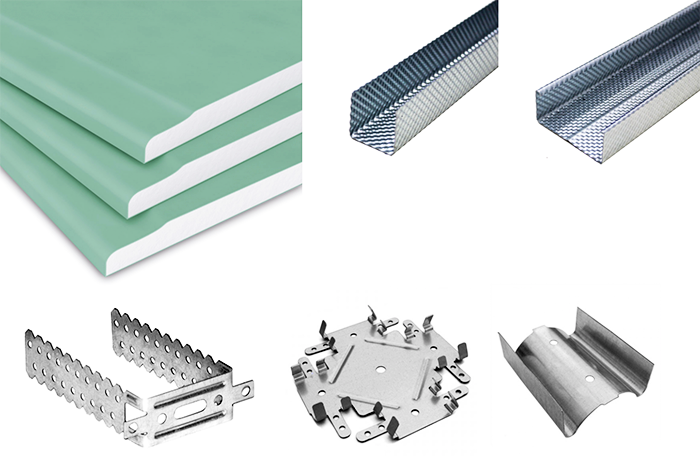

From the materials you will need:

- profile: guide, rack-mount, ceiling, protective corner;

- direct suspensions;

- sealing tape;

- primer;

- reinforcing mesh or tape;

- dry mortar for fixing GKL in a frameless way;

- mounting foam;

- putty (ready or dry mix);

- self-tapping screws for fastening GKL;

- dowels for attaching profiles;

- insulation.

Fixing drywall sheets

Drywall can be attached to a wall or ceiling in a frame and frameless way. The choice of fixation depends on the design and purpose of using the GCR. Multi-level ceilings, partitions and walls that will be insulated are equipped with a metal or wooden frame. If you just need to level the surface, you can use glue or mounting foam.

metal profiles

Installation of drywall on a metal profile allows you to create multi-level ceilings, niches, arches, decorative structures, interior partitions, etc. It also becomes possible to level surfaces with large differences, produce additional insulation and sound insulation, and lay various hidden communications. The disadvantage is the reduction in usable area.

Fastening sheets start from one of the corners with metal screws. The screw head should be slightly “drowned” in the GKL (about 1 mm.). The sheets should be staggered, the distance between the screws should be no more than 250 mm, and the distance from the screw to the edge of the sheet should be 10 mm.

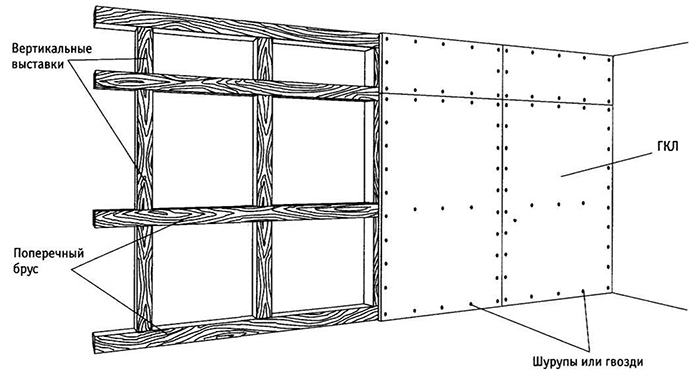

wooden frame

This option is less preferable, since the wood is deformed under the influence of temperature and humidity. These deformations can lead to cracks in the finished surface. Installation of drywall on a wooden frame is similar to fixing drywall on a galvanized profile.

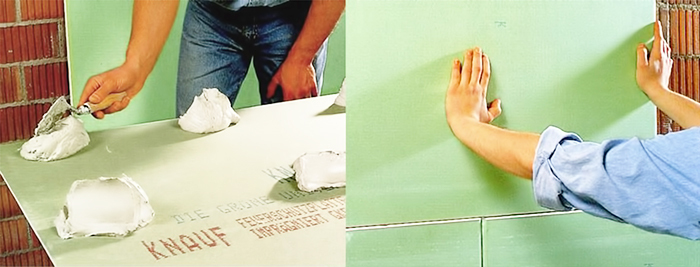

Glue

It is not always advisable to mount the GKL on a metal or wooden frame. In some cases, fixing sheets can be done with glue. The technology of its application depends on the degree of unevenness of the walls or ceiling. If the surface defects are insignificant, then the adhesive composition is applied in a thin strip around the perimeter and then a few spot strokes in the middle. If the potholes or bumps are slightly more than 10 mm, then the glue is applied in a thick layer pointwise around the entire perimeter of the sheet.

When the surface has large potholes, they can be pre-sealed with inserts from GKL scraps and only after that whole sheets can be mounted.

Foam

Installation of GKL on mounting foam is preferable, especially if the walls are made of natural wood. Before sticking the sheets, regardless of the fixing composition (foam or glue), the walls are cleaned of the old finish and primed. GKL sheets are cut to size, treated with a primer and numbered.

The foam is applied to the sheet, after which it is applied to the installation site and pressed tightly. Drywall must be kept pressed until it sets. Cut off excess foam with a knife.

Features of additional work during the installation of GKL

Drywall is used not only for leveling walls, creating beautiful multi-level ceilings and interior partitions. With the help of GKL, you can perform high-quality heat and sound insulation, disguise engineering communications and make the basis for any decorative finish.

Insulation installation

Often there is a need to insulate a house or apartment from the inside. The selected insulation is laid between the frame rails. The fixation of the material depends on its type. For example, expanded polystyrene can be glued and additionally fixed with special dowels. Joints must be sealed with sealant (including silicone). It is also necessary to equip steam and moisture insulation.

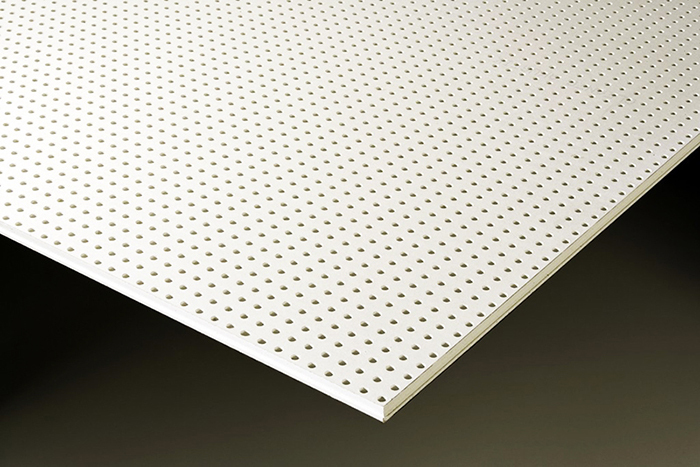

Sound insulation pad

To ensure good sound insulation of the walls, you can use special acoustic plasterboard or traditional soundproofing materials. This can be foam rubber and polyethylene foam, acoustic membranes, films and non-woven canvases, mineral wool, etc. The laying of sound insulation is carried out in almost the same way as in the case of insulation.

Bookmark electrical equipment

The location of the installation devices and electrical wiring must be thought out and installed after the frame is assembled and before the insulation and sheathing of the GKL frame. Wires are recommended to be laid in metal or plastic corrugated pipes. Next, the wiring is carried out along the walls and ceiling and the installation of mounting boxes.

Finishing work

Before finishing, drywall sheets should be prepared. To do this, you need to lightly walk with sandpaper or a grinder over the entire sheet and with effort - along the seams, roughness, places where self-tapping screws are attached. After sanding, apply a primer with moisture-repellent and anti-fungal properties and allow it to dry for 24 hours.

After such preparation, you can glue wallpaper, tiles, decorative panels on drywall, or simply apply paint.

Errors when working with drywall

The technology of plasterboard wall and ceiling cladding is not so complicated, especially if you follow the instructions of specialists. However, both beginners and some "masters" make the same mistakes, namely:

- Incorrect profile installation. Often, inappropriate fittings are chosen, suspensions are not used, the stands are fixed on the wrong side.

- Using the wrong tool when cutting a profile.

- Choosing the wrong profile for the frame: instead of a wall profile, a ceiling one is used.

- Incorrect fastening of the GKL. Drywall should always be installed facing outward.

- Creation of a plasterboard surface from samples. You should not do this unless it is absolutely necessary.

- Leaving a chamfer on the sheet.

- Extension of the walls of the profile, which reduces to a decrease in its bearing capacity.

- Rejection of hangers.

- Violation of the frame scheme.

- Installation of plasterboard sheets in a row.

A few words at the end

There is nothing difficult in working with drywall, especially if you choose the right material, accessories, follow the recommendations of specialists and have at least minimal skills in working with tools. We hope that the information we have provided will help you when you decide to independently finish the walls and ceiling with plasterboard sheets in your house or apartment.

Basements in cities and private houses should not be built, they are often drowned. Regarding similar...

There was an idea to buy a country house with a carport. We found an interesting place near the…

We have been wanting to buy a painting on canvas for a long time and recently we were pleased with this by the company Va…

Didn't like the renovation. The kitchen is narrow, it was necessary to visually solve this particular pr…

unlike the palaces of our president's friends, this is just a miserable hut, albeit in style ...

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thank you. Briefly and clearly...

Karting. I want to help children! &nbs …

Now there is a very interesting and effective option for heating - plasterboard pa…