In different places of any apartment, a wall or part of it can be tiled. This hygienic and environmentally friendly coating is easy to clean and diversifies the design of the room. But it is always possible that the need arises to hang some other object on the tiled wall - a shelf, a mirror, hooks. Of course, you can glue something. But it’s scary to hang a heavy mirror or shelf on glue. A powerful hook must be set. And it needs to be screwed into the wall. This means that a hole must be drilled in the surface. And at this place the tile is already glued and you need to drill a hole in it. How to drill a tile without chips and cracks? Not all home craftsmen can do this. But there are simple ways.

Read in the article

- 1 Repair tasks requiring tile drilling

- 2 Drilling technology

- 3 Tool selection

- 4 Conclusion

Repair tasks requiring tile drilling

The bathroom may require plumbing and the walls are already tiled. The owner wanted to get an electrical outlet elsewhere. And the hostess needed to hang an additional mirror, shelf and hooks. And they remembered about the heated towel rail and the clothes dryer in time. So you need to drill the tiles on the walls. Since during the production of the tile itself, it is fired at high temperatures, it becomes very hard and brittle.

Drilling technology

First, before drilling, you need to check how tightly the tile is glued to the wall. Masters define quality by ear. If, when tapping on a tile, the sound is dull, it means that the tile is glued tightly, and you can drill it. If you hear a slight ringing, then there are voids under the tiles. In this case, the likelihood of cracking is high.

A common thing that always exists when drilling tiles is that they are slippery. And the drill is difficult to hold in the desired point. To avoid slipping, you can stick a piece of masking tape in the drilling area or carefully manually scratch a cross on the tile surface, scratching the hard layer of the cladding. And place the drill exactly in the scratched cross. You can use a "conductor" - a piece of wood with a hole. But during operation, it must be pressed tightly against the wall, preventing it from moving. It is only necessary to drill the tiles from the tiled side.

Tool selection

The result of the work is largely determined by the choice of tools and accessories. The main assistant of the master in this delicate work is an electric drill or screwdriver with a rotation speed of up to 1000 rpm. It is also necessary to choose the right drills in accordance with the task ahead.

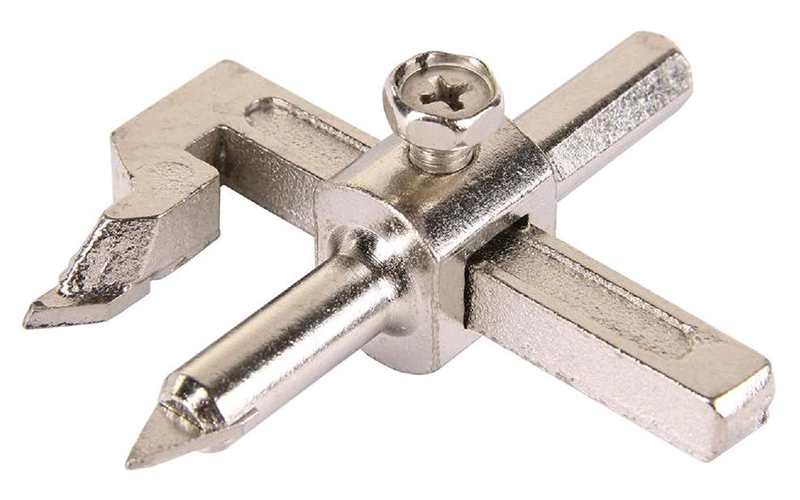

In this case, the problem is characterized by the hole diameter. It can be small - up to 15 mm in diameter, and large - for installing a socket, up to 60 mm in diameter. In the first case, drills with a sharply sharpened victorious tip are chosen. In the second case, you need a hole saw or a circular drill (ballerina).

Drilling holes should be started with low pressure at low rotational speeds of the drill, after passing the glaze layer, it is necessary to gradually and carefully increase the speed, but not more than 1000 V minute. If you need to drill a tile that has not yet been glued to the wall, then it is recommended to hold it in water for about an hour. The material will become softer, which will reduce the likelihood of cracking. The drilling site should also be regularly moistened with water for cooling.

Large holes can be drilled step by step. It is necessary to draw the outline of the future hole on the tile. Then, with a small-diameter drill, stepping back into the drawn contour, as close to each other as possible, it is necessary to drill holes. Then, with pliers, cut the jumpers and the edges of the hole obtained in this way, go through the abrasive installed in the same drill.

Since the tile lies on a wall made of concrete, brick or plaster, after drilling a hole in the tile itself, you need to change the drill to match the new material. The main thing, when drilling a tile, is not to forget to turn off the drill mode on the drill.

Conclusion

The home craftsman really needs to be able to do a lot. Now there are a lot of sentences like "Master for an hour", but it's better to know more yourself. It's nice to look at the results of the work of your own hands later. And you can brag to your friends. And teach sons by example.

The article was written by an amateur from construction, who does not know what the rigidity of concrete is, what ...

The palace is gorgeous! To this palace, there would still be a hostess with brains, and not a natural one made ...

A good heating option. Checked on its own loggia. They installed a drywall ...

Don't tell tales about the responsibilities of electricians and utility companies. Wha ...

Indeed, there are examples.

Permenergosbyt does not need meters at all, none at all. I passed the testimony monthly, pla ...

Very thoroughly, as a good teacher from whom a bad student will receive a 5. Thank you.

She is a gypsy by mother, that's where the taste of such a crazy color comes from.

A talented person is talented in everything. Creative, tasteful and with a knowledge of history. All by ...

I bought the meter and installed it myself, then I called, went for six months to get it sealed ...

You can have Aunt Valya in the hayloft, and the Agreement will contain a calculating meter, all the rest ...

why so many houses would it be better to make someone happy bought a house, to someone who doesn’t have ...

There are two lines in the house, I use one, the other is not connected to consumers, the cable is twisted ...