The project of heating facilities - is drawing fire future designs on paper. you must think wisely before the start of laying all the points and draw a sketch correctly.

Studying projects of houses with a fireplace, you should know the following parameters:

- what size to fill the foundation under the fireplace;

- height of the room;

- high strength brick constructions;

- compliance with fire safety measures;

- attractive appearance of the fireplace.

Correctly charting fireplace made of bricks will save time and effort, and will make it possible execute plans construction in the best possible way, as well as to avoid difficulties in operation. Projects of brick fireplaces

Corner fireplace and its uniqueness

Consider a detailed drawing of the angular masonry fireplace brick and poryadovkoy description. To date, there are fireplaces myriad projects, but at the moment we offer you a convenient built-in corner fireplace, which can be set in a small, not less than 12 m2 room, since oxygen is not sufficient for its heating. To create it is necessary to find a mason 4 - 5 digit, that he possessed the subtleties of the construction of this facility, or delve into the intricacies of this process on their own.

It should be remembered that the internal structure of the fireplace creates almost the same, and a fire burning in the furnace of the same.

At the corner of foci has its advantages:

Its peculiarity is that it is not in the center of the structure, and in the corner, and has a small size. In addition, it transmits the heat energy evenly throughout the room.

Folded neatly, with minimal variations and tolerances in the construction, is a corner fireplace heating equipment, carries a certain decorative beauty and shows the status of the host structure.

Its disadvantage is expensive, decorative finish.

Bricks for construction of facilities needed high marks, of course, you can lay 100 mark, but it must be remembered that this material is of poor quality for its putting some. In this case, if you build this brick fireplace, it, on fire safety should be plastered.

This mark brick used for uploading the outer casing and the construction of the pipe. A spread inside of the furnace of refractory bricks.

See also: apparatus for fire tube.

- By this design of the bricks is needed to fill a single base in order not to disturb the main foundation, since the heater has its own shrinkage.

- Is required between the wall and the future fireplace attach special heat insulating material or put in the clutch quarter bricks, i.e. in an edge (preferably via two series routed wire structure for strength).

Its masonry is made on the project, performing the dressing seams. Work is carried out without haste, because the clay solution has the ability to swim.

It is desirable to observe the level of the horizon, and a vertical surface point equal to the diagonal. In this respect the rules depend on the quality of output to the outside the combustion products.

See also: Types of pavilions with beautiful fireplaces.

Scheme rectangular chimney and drawing

Its size is 5 × 2,5 poryadovkoy brickwork consists of 33 rows

This construction was used without door to the furnace. The designer, creating this drawing, using flue has a through channel that provides good traction. In this regard, its heat capacity is reduced to increase the efficiency of the structure. To do this, use the standard methods, such as empty channels along the masonry firebox and chimney.

- The inner part of the firebox should be spread from refractory bricks which can withstand 1100 degrees.

The main part of the massive fireplace corpulent ceramic bricks laid high quality, it must match the mark 125 and above, its heating temperature is 750 degrees.

You should be aware that the refractory and ceramic brick is prohibited to dress, but they can be connected through a wire cross-section of 3 mm, laid in the seam between the bricks.

Poryadovaya circuit rectangular chimney 5 × 2,5 of bricks

Spreading this structure should withstand the same thickness between the bricks equal to 7.5 mm.

If the material contains defects, assume oblique angles, then they should stosyvat from each other, so you will achieve the desired weld thickness.

Rows should be checked by a plumb or level to achieve the correct geometric shape design.

According to the drawing are master potters, even with a great experience, they are reconciled with him.

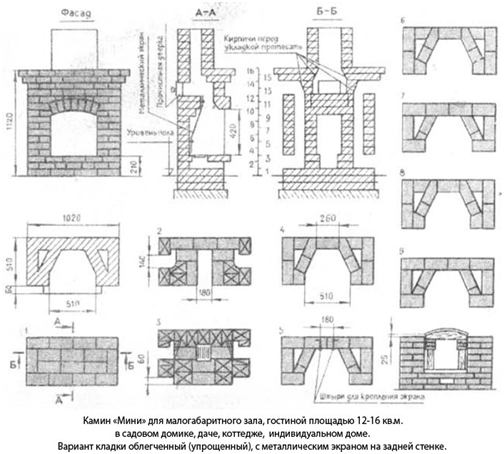

Drawing mini fireplace

This heater can be installed in a room of at least 16 m2. It is inserted into a barrier to heat two rooms. To increase the heat, the furnace without refractory bricks laid. Thus, the ceramic brick is heated much faster, because it retains less heat capacity of the array than the refractory.

- In this case, to protect the combustor from the high temperatures master - setter applies instead of hard tooth, metal sheet 3 mm thick.

Drawing fire brick is attached below in the description. If the master has small skill in this direction, instead of the arch of the portal can build horizontal overlap. To do this you need 2 brackets of the desired length of metal.

A positive feature of this fireplace is the fact that purchasing materials for its construction, the minimum you expend their funds.

For the erection you will need:

- Ceramic brick 235 pieces;

- clay - 0.12 m3;

- Sand - 0, 3m3;

- Clean out the door - 1 piece;

- valve furnace - 1 unit;

- grate - 1 piece;

- Duszniki - 2 pieces;

- Steel sheet thickness - 3 mm and the size of 0, 25 m2;

- roofing - 1.5 m2;

- Cement - 15 kg.

Fireplace "mini" and poryadovaya scheme masonry

To maximize the efficiency of the efficiency of this structure, the side walls of the firebox spread angle 25gradusov.

The rear wall 10 is laid out in rows in a conventional manner, i.e. horizontally. Starting with the 11 series nominated for a quarter brick at an angle of 30 degrees to the inside of the furnace. Thus the action of the tooth formed pass chimney, into the joints between the bricks are inserted metal pins hereinafter, they will be attached sheet of metal.

Below there is a drawing of a metal for the firebox.

Due to the absence of firebrick in this structure, the space in the room heats up much faster, as laid out side air ducts.

In the lower part there are openings through which cold air flows, and heated by the furnace hearth hot air through the "Duszniki" located in rows 13 and 14, already located inside the hot room air. Thus, its efficiency is increased to 15, 20%

English fireplace medium size

English fireplace made of bricks with their hands is one of the oldest, which is being built at all. its called classic brick fireplace open type.

The parameters rank the following features:

- protruding tooth;

- open fires;

- an inclined rear wall fracture.

The inner recess of the furnace or hearth of refractory bricks laid on a solution which includes a clay and fireclay crumb, as well as little cement. Outer loop structures created from ceramic, solid material.

Circuit elements and a fireplace in the English style

This scheme is relevant to most models of the English type.

This scheme is complex in the English style, but pays in that it is stable and good thrust efficiency. Drawing fire brick English style 5 × 3 and its poryadovaya scheme.

For its construction, you will need:

- corpulent ceramic brick - 350 pieces;

- fireclay bricks - 125 pieces;

- sand-clay solution - 215kg;

- Refractory solution - 155kg.

Below is a detailed drawing of the heater English 5 × 3 of bricks

The first four rows of the base ceramic bricks laid mark 100, then applies a high-quality material grade 150 and above.

This structure is installed in the premises of at least 80 m3 a common space. Poryadovkoy studying it, we should note the following points, please note that there is no ash pit and grate.

If the room has a small amount of hermetically sealed windows on all sides, you must set the oxygen supply from the street into the furnace for better combustion.

To create overlapping inserts for the twelfth row stacked Area of steel strip 2 and of the same material.

In this construction, at 16 - 17 number of the cleanout door is provided, which is mounted on the rear wall. This restricts the placement of the hole to fit the fireplace bearing wall or to the pier. In this case, according to the heater does not get warm the second room.

To maintain elasticity and a solution of its natural setting ceramic brick, before erection of masonry construction, should be soaked for 5 minutes in a water tank. Heat resistant brick wipe with a damp cloth to get rid of dust.

After the completion of the construction of the English fire, should be within 3 weeks gradually heat thoroughly - dry it, and only after the lapse of this time, it is possible to lay up to half of the furnace. After a month, you can flood the heater at full power.

Following this rule, you will give the solution to naturally grasp, if it fails, then you are putting your design constraints in service life. The decision is yours.

A three-level masonry fireplace grate

This design is the Russian version, but the basic elements are taken from the subjects of English and Swedish modeling.

photo fireplace, consisting of three levels

Thrust in the pipe of this structure consistently good, even at the height of three meters, due to the large cross-section of the inside of the chimney.

It should be remembered that this building used in those areas where high levels of humidity.

drawing the three-level scheme fireplace grate

Masonry will need the following materials:

- ceramic brick - 620sht;

- fireclay bricks (refractory) - 220 pieces;

- grill grate 420h200mm - 2 pcs;

- valve smoke 260h260 mm - 1 piece;

- Area steel №40 - 150cm;

- Area steel №60 - 100 cm;

- steel strip 4h60 mm - 300 cm;

- clay solution - 750 kg.

After examining the above poryadovkoy drawings and fireplaces made of brick for the construction of their own hands, you should know how to calculate all the dimensions of the structures.

Be patient for self-build or find a master - stove-maker with a good skill to install this heating equipment.