When arranging a personal plot, I want to make it not only beautiful, but also as functional as possible. To decorate the adjacent territory, decorative trees and shrubs, park sculptures, artificial slides or mini-reservoirs, gazebos, fences, etc. are used. Also recently, gabions have been actively used in landscape design again. This element of decor is not only an adornment of the adjoining and backyard territory, but also a functional design that you can make yourself. In this article, Homius experts will tell you how and what to make gabions with your own hands, and step-by-step instructions will help you avoid common mistakes.

Read in the article

- 1 What is a gabion

- 2 How is the gabion

- 2.1 What wire is used for the frame

- 2.2 Types of filler and the nuances of its installation

- 3 Typical shapes

- 3.1 flat and box

- 3.2 Cylindrical and artistic

- 4 Key features of gabion manufacturing

- 4.1 Materials and tools

- 4.2 Features of collecting the walls of the frame

- 4.3 Gabion filling

- 5 Independent production of gabions

- 5.1 Flower beds

- 5.2 DIY garden bed

- 5.3 Gabion bench

- 5.4 Alpine slide

- 5.5 Low fence with posts

- 5.6 vertical fence

- 5.7 Gabion fence on channels

- 6 The use of gabions in landscape design: photo examples

- 7 A few words at the end

What is a gabion

Gabion (Italian) gabbia) translates as "big cage". The prototype of modern gabions in the 16th–18th centuries. used for military purposes as a defensive structure. Artillerymen filled wicker baskets without a bottom with stones, rammed earth or sand and placed them in front of the guns, thus obtaining more or less reliable protection from cannonballs and bullets. Later, in the 20th century, the baskets were replaced with sandbags, from which a makeshift wall was built around artillery pieces and machine gun nests. Even now, gabions made of steel wire or durable fabric are used on NATO military bases in the Middle East.

Engineers have found application for gabions in civilian life. They are used to strengthen slopes along rivers and mountain roads, building protection against floods and landslides. The advantages of the design were also appreciated by landscape designers who use gabions in the implementation of their projects.

How is the gabion

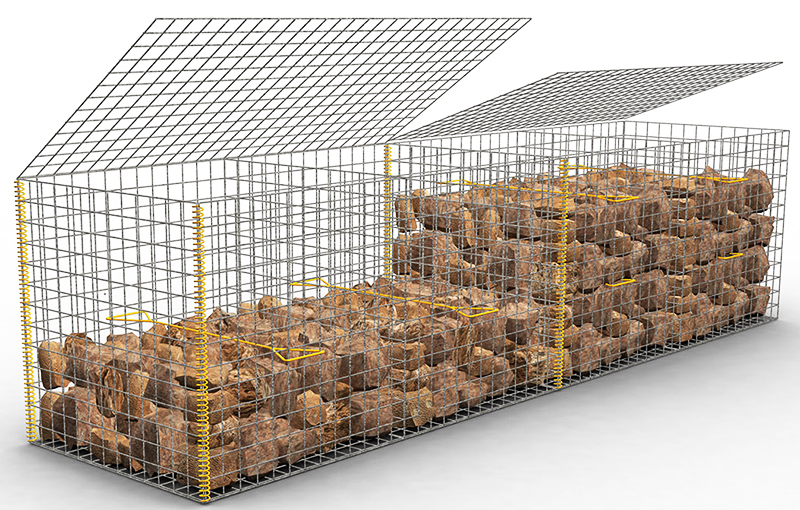

There are many types of gabions, but they all have a common structure. Regardless of the configuration and purpose, they are made of metal mesh or rod. Gabion is a lattice frame filled with natural stone or other available materials.

What wire is used for the frame

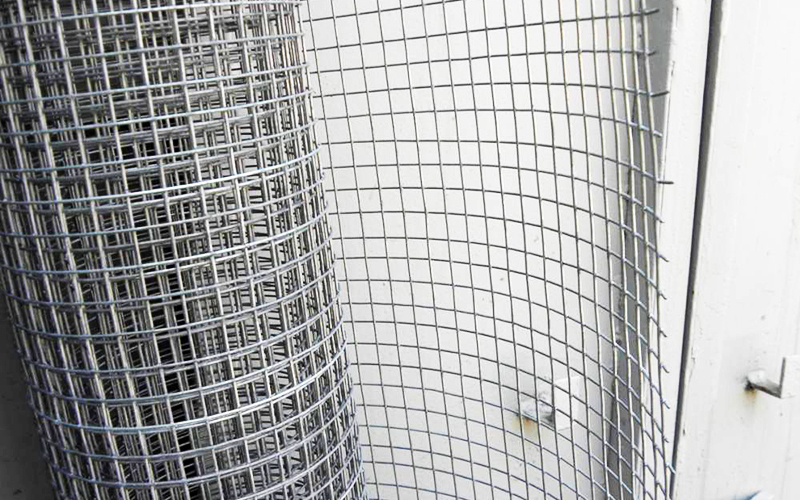

For the manufacture of gabions, twisted steel wire with a cross section of 2–6 mm is mainly used, since the thinner material will not withstand the high load created by the filler. To ensure that the structure is durable and does not collapse under the influence of rust, galvanized or polymer-coated metal is used. The wire with polymer protection tolerates high humidity, temperature changes and chemical influences well.

For the manufacture of gabions, the following types of wire are used:

- galvanized (zinc layer density from 250 g/m2);

- with anti-corrosion coating of zinc-aluminum alloy in the ratio of 90 and 5%, respectively;

- with PVC coating - due to the special composition of the coating, the wire does not interact with air, moisture and other atmospheric influences, and is also resistant to critical temperatures and their differences.

There are two technologies for creating a gabion from a metal mesh:

- frame - a metal mesh is used for manufacturing, which is attached to a rigid metal frame;

- welded - metal rods or wires are intertwined and welded together, forming a cylindrical or box-shaped structure.

Structures made using the second technology are the most durable. In addition, they are more attractive, because they can be given any shape, turning into an original art object.

Types of filler and the nuances of its installation

Traditionally, solid or split rock stones are used to fill gabions. In particular, these are:

- basalt;

- granite;

- simple cobblestones;

- pebbles of different sizes;

- quarry stone;

- crushed stone;

- diorite;

- quartzite;

- porphyrite;

- crystalline schists.

The following requirements are imposed on stones for gabions:

- specific gravity 18–25 kN/m3;

- mechanical strength from 400 kgf/cm2.;

- resistance to low temperatures over MP350;

- water absorption is not more than 0.6%;

- softening coefficient from 0.9 units.

These requirements are mainly imposed when using gabions in construction (foundations, bridge supports, protection of slopes of roads, rivers, etc.). Stones used in landscape design must meet two basic requirements:

- be larger than the cell size;

- have light gray or warm shades that blend well with the background of the ground or lawn (they are more preferable).

In addition to stones, almost any materials at hand can be used as a filler in gabions:

- fake diamond;

- saw cuts of trunks, logs;

- cones;

- whole or broken pottery;

- brick;

- pipe samples and much more.

If wood is used as a filler, then it must be treated with protective compounds before laying.

Typical shapes

Despite the variety of mesh structures, there are 4 main types of gabions: flat, box-shaped, cylindrical and artistic. Box-shaped models are more popular, from which, as from a designer, you can make a decorative fence, garden furniture and other elements for landscape design.

flat and box

Flat (“Reno mattresses”, mattress-mattress) gabions - mesh blocks 1–22 m wide, 3–6 m long and 17–30 cm, inside which membranes are necessarily installed to maintain shape and give strength partitions. The low height allows structures to follow the curves of the landscape, making them excellent for shaping and reinforcing ravine slopes and coastlines. They are also used as a foundation for massive box-shaped gabions and terracing of plots. Mattress constructions are easy to install and require less filler.

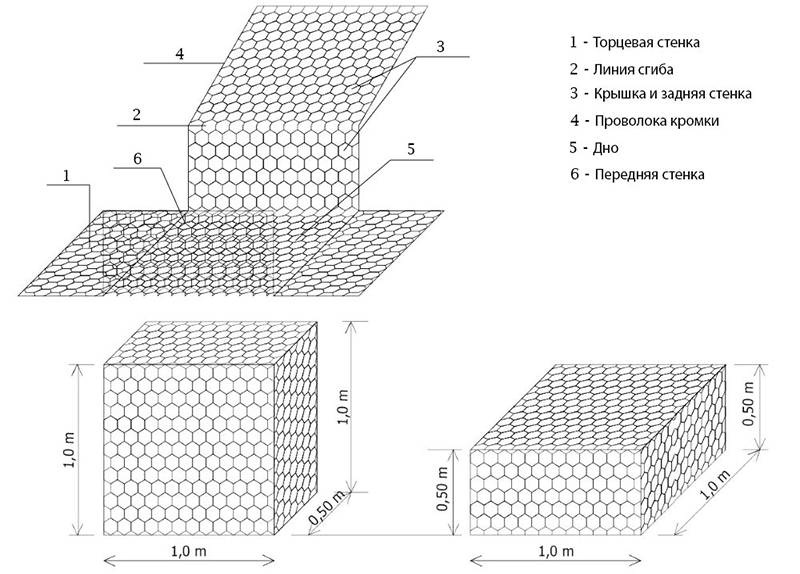

Box-shaped gabions or "jumbo" have the shape of a classic cube or parallelepiped and are made of double-twisted steel wire, and the cells are made in the form of a regular hexagon. The wire gives the structure increased strength and reliability due to uniform distribution over the grid. In addition, double torsion prevents the structure wall from spreading in case of mesh damage.

The standard dimensions of box gabions are 2–6 m in length, from 1 m or more in height and 1 m in width. If the length of the structure exceeds 2 m, then it is equipped with membrane partitions located at a distance of 1 m from each other.

Also, the gabion box can be made of a metal rod using welding, and the cells in this case are square. Box structures are used for the construction of fences, retaining walls, fortifications on the banks of rivers and slopes of ravines, as well as for the design of flower beds. In addition, they can be used as a foundation only if a large load is not expected on it.

Cylindrical and artistic

Cylindrical gabions or bags are basically in the form of a roller without jumpers and stiffeners, and due to fasteners in the form of tucks, they resemble candy. Similar structures are created on the order of 2–4 m in length and 65–100 cm in diameter. Due to the absence of tightening membranes, cylindrical gabions acquire plasticity and can be used on complex terrain. In landscape design, they are used to strengthen the bottom and coastal line of reservoirs, create retaining walls, etc. There are also cylindrical welded gabions that function as small pillars.

Artistic gabions are actually art objects. They are made in the form of figures of animals or a person from metal rods, for the connection of which a welding machine is used.

Key features of gabion manufacturing

Before proceeding with the creation of gabions, it is necessary to understand the key points of their manufacture. The decorativeness, strength, reliability and stability of the structure directly depend on how correctly all stages of work are observed. The features of the manufacture of gabions, regardless of their purpose, include:

- choice of material for the frame and filling;

- mesh attachment methods;

- tools for making a frame;

- specifics of filling boxes;

- structural fasteners.

Materials and tools

Factory-made gabions are made of mesh in accordance with the requirements of GOST and TU. In the GOST R 51285-99 standards, they are designated as gabion mesh products (GSI) and must meet the established requirements for both the materials used and the dimensions designed for specific loads. The same rules must be observed in the self-production of gabions at home.

For the manufacture of gabions, a grid of double-twisted galvanized wire with a cross section of 2–4 mm is used. When creating a structure from a polymer-coated mesh, the wire diameter must be increased by 1 mm. If the gabion is made using welded technology, it is required to use a metal rod with a thickness of 6–8 mm.

In the manufacture of GSI, in addition to the base material, a knitting wire is also required, which is used to fix the mesh on the frame and tie the walls together. The following requirements are imposed on the binding component of the gabion:

- the wire should not have breaks;

- splicing of the wire is carried out by the method of twisting or extension;

- twisting should be no more than 20 mm in length, so it must be done very high quality and accurately;

- no more than one twist per 20 m of the web is allowed.

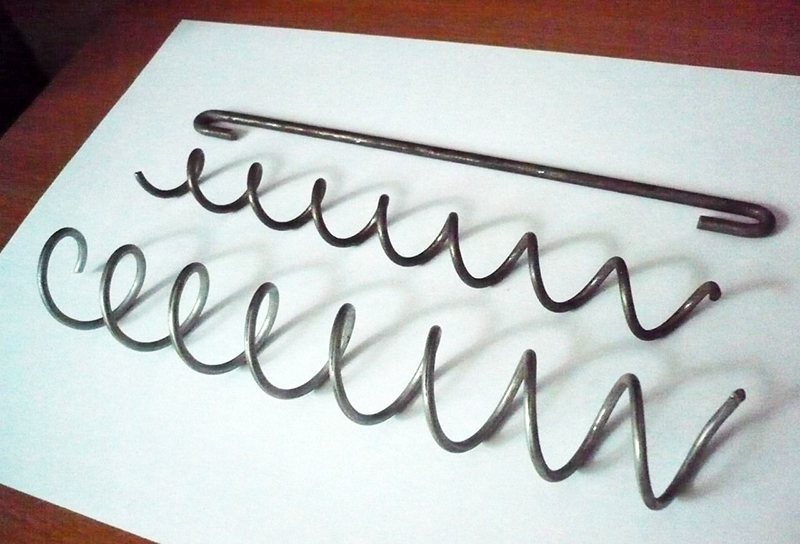

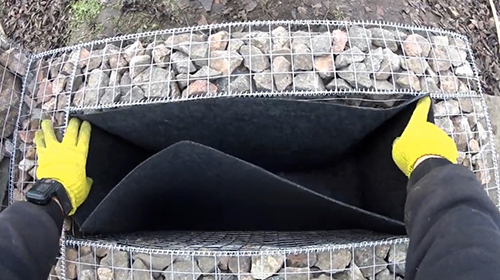

You will also need reinforcement to strengthen and stiffen the frame, metal spirals and wire staples, geotextiles to save bulk filler.

Before you make a gabion, in addition to materials, you need to prepare the necessary tools. They are easy to use and almost everything is in any household:

- mechanical or pneumatic stapler for connecting the mesh with wire staples. The first option is completely autonomous, but with a compressed air tool, it is easier and faster to work, although it is tied to a compressor. However, it is not advisable to purchase a pneumatic stapler for one-time work, therefore, if necessary, it is better to rent it;

- pliers - needed for biting off the wire of the required length and twisting it;

- sledgehammer or hammer;

- shovel;

- metal scissors;

- plumb;

- welding machine (depending on the assembly technology).

Features of collecting the walls of the frame

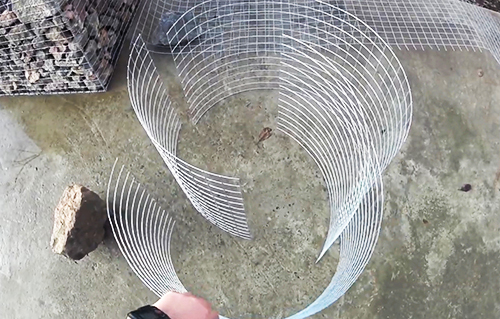

The side and bottom ribs of the GBI frame are mainly fastened together using a wire spiral. You can make it yourself by winding the wire on a pipe with a diameter of 20-40 mm. In addition to spirals, special galvanized steel brackets can be used, installed in 120–150 mm increments.

In order for the structure to retain its geometric shape, it is necessary to install stiffening ribs (U-shaped jumpers) inside it, made of wire of the same thickness as the mesh. This will avoid deformation of the walls under the load created by the filler.

The distance between the jumpers depends on the design of the GBI and the thickness of the wire. It is recommended to first lay a layer of filler, set the tightening and continue filling the gabion.

Gabion filling

When creating gabions, it is very important to choose and lay the filler correctly. The filling of mesh structures can be carried out with any stones, but with the obligatory displacement of the joints (according to the principle of brickwork). The size of the elements of any filler should be 2–5 times larger than the dimensions of the cell. Also, do not use too large stones, as there is a lot of empty space between them.

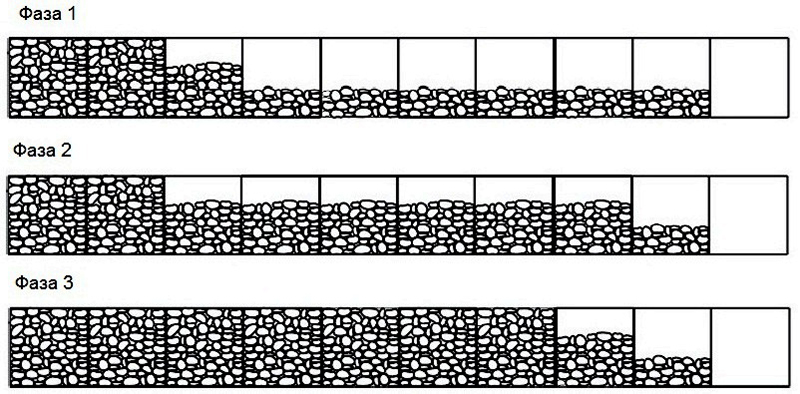

If the GBI has a height of 500 mm or more, the filling of all sections occurs simultaneously and gradually, that is, they are first filled up by ¼ of their volume. Mattress gabions can be filled in 1-2 steps. After that, the first 1-2 sections are completely filled, and the subsequent ones are half filled.

The next step is to lay stones to the top in all sections, and the filler should protrude 20–50 mm above the upper level of the box, as they will level out and settle to the desired level.

If it is planned to install another structure in length next to the first gabion, then the last section of the box is temporarily left empty for connection with the subsequent part of the GBI. In large boxes, in order to save filler, it is recommended to lay stones only along the walls of the structure. In the middle of the box, which should be approximately 1/3 of the volume, any solid material of a fine fraction is poured. However, this is acceptable if the gabion does not have constant contact with water.

Independent production of gabions

Gabions can be ordered from a landscape design company or you can make your own. In this, in principle, there is nothing complicated, you only need a minimum set of tools, suitable materials and desire. We offer you to get acquainted with several options for gabions with step-by-step instructions for their manufacture.

Flower beds

Making one or more gabion flower beds for your summer cottage or personal plot is quite simple, especially if you follow the recommendations below. The shape and size of the structure depends only on your preferences and capabilities.

First of all, you need to create a drawing or sketch in order to have an idea of \u200b\u200bhow the flower bed will look like, as well as calculate the dimensions and details. Next, you need to level the site where the structure will be installed, prepare materials and tools.

| Illustration | Action Description |

| From a gabion mesh with a cell of 25 x 25 mm, we cut all the details of the structure. |

| Using spirals or staples, we assemble the walls of two boxes (outer and inner). |

| Insert one box into another. As a result, there should be a distance of 100–150 mm between the outer and inner walls of the flower bed. We fix the bottom of the flower bed and turn the structure over. |

| We fill the gabion by 100 mm, after which we install wire jumpers. We repeat the operation until the gabion is completely filled. As already mentioned, the stones should be higher than the wall of the structure. |

| After the stones have settled, we install the cover, and place a geotextile bag inside the structure. |

| We fill the fertile soil inside the flower bed, moisten it and plant the plants. So that the earth does not dry out, it can be covered with stones, shards, etc. As a result, you can create such a composition from several flower beds. |

DIY garden bed

A garden is not just land with planted or sown useful plants. It can be beautiful and look like flower beds. In principle, gabion beds are structurally similar to flower beds, with the difference that the space filled ground, there should be more, and for the manufacture of walls a knitted or welded mesh with a thicker wire. To create a gabion garden, you need the same tools and materials as for a flower bed, as well as a sketch and drawings with dimensions.

| Illustration | Action Description |

| We assemble the walls of the outer and inner boxes. The connection is made using spirals. |

| We install the bottom of the gabion, turn it over and install the structure on a pre-prepared place, which is covered with geotextiles. |

| We begin to fill the structure with stones, making the bandaging of the walls with wire ties. |

| It is also necessary to install screeds in the space, which will subsequently be filled with earth. We fill the gabions with stones to the very top, and after shrinkage we close the mesh cover. |

| Inside the empty space we lay agrofibre and fill in the fertile soil. Gabion covers can be lined with boards pre-treated with a protective compound. The result will be several beds with benches around the perimeter. |

Gabion bench

We suggest that you familiarize yourself with the video instruction for the manufacture of a gabion bench, which can be placed around the hearth or barbecue. Its creation is practically no different from other designs.

Alpine slide

You can create an original "alpine hill" type flower bed that will decorate any backyard or summer cottage. See this video for instructions.

Low fence with posts

Fences are the most popular designs that perform a practical and decorative function. And recently, fences made of gabions have been in great demand. Their design features allow you to create fences of almost any configuration. On the video shows the process of creating a low fence with posts.

vertical fence

The video provides instructions for creating a vertical gabion fence. The main nuance of the construction of gabion fences is the presence of support pillars.

Gabion fence on channels

In order for the gabion fence to be stable, it is necessary to dig a metal pipe or channel into the middle of the pillars. It is also necessary to install wire ties more often, which will not allow the walls of the gabion to disperse under the weight of the filler. You can make the design more original by using multi-colored stones, arranging different materials or organizing decorative lighting. This video tutorial will help you create a gabion fence.

The use of gabions in landscape design: photo examples

The use of gabions is a great opportunity to decorate and equip a backyard or summer cottage in an original way. You can take a ready-made idea from the Internet or develop your own design. We offer several such options for the use of gabions in landscape design.

1 out of 12

PHOTO: i.dobrzemieszkaj.pl

PHOTO: www.myhomeinspiration.net

PHOTO: unipack-ug.ru

PHOTO: 097.6597919.net

PHOTO: mykaleidoscope.ru

PHOTO: pro-dachnikov.com

PHOTO: hutorborodkin.ru

PHOTO: dizainexpert.ru

PHOTO: gabionika.by

PHOTO: rehouz.info

PHOTO: housejournal.ru

PHOTO: dacha.help

A few words at the end

Of course, you can order a gabion from a landscape design company. But it is better to do it yourself, especially since it is not difficult, and as a result you will get an original design. We hope that the information provided in this article will help you when creating a gabion with your own hands.

Basements in cities and private houses should not be built, they are often drowned. Regarding similar...

There was an idea to buy a country house with a carport. We found an interesting place near the…

We have been wanting to buy a painting on canvas for a long time and recently we were pleased with this by the company Va…

Didn't like the renovation. The kitchen is narrow, it was necessary to visually solve this particular pr…

unlike the palaces of our president's friends, this is just a miserable hut, albeit in style ...

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thank you. Briefly and clearly...

Karting. I want to help children! &nbs …

Now there is a very interesting and effective option for heating - plasterboard pas …