Rubber flooring for the courtyard of a private house is a great alternative to natural stone, concrete, ordinary paving slabs, paving stones, asphalt and other surfaces used in the arrangement territory. A relatively new material, since it appeared on the market and in stores not so long ago, but it is already in demand and popular.

The rubber covering is used to create the foundation for the courtyard of a private house in any place.

Design solutions for summer cottages: types of rubber tiles

Content

- Design solutions for summer cottages: types of rubber tiles

- Material characteristics

- Rubber seamless crumb coating, self-leveling

- Decorative laying of tile material in the yard

- VIDEO: Laying rubber crumb covering in the country.

- 50 options for rubber coating of the courtyard of a private house:

There are several different types of yard rubber available on the market. It comes not only in various thicknesses and geometric shapes, but also in all kinds of colors.

This is the newest trend in landscape design.

You can cover the courtyard area and pave rubber paths using the following types of tiles:

- Standard square. Most often this is a size - 50 * 50 cm and 33 * 33 cm, thickness - from 1 to 4 cm. The front side is both smooth and embossed with various volumetric patterns.

Rubber tile is a coating made on the basis of crushed rubber (crumb rubber) and polyurethane adhesive.

- Paving stones. Tiles of various shapes (bone, timber, coil, brick, etc.), 2-4 cm thick. The surface is smooth or textured.

Rubber paving stones are considered a relatively new solution in the domestic building materials market.

- Ribbon. Rubberized tape tracks rolled into rolls up to 10 m long, 30 to 50 cm wide.

Rubber flooring on playgrounds and garden paths has become popular due to its speed and ease of use.

The specific type of coverage is selected based on the general design and layout of the site, as well as the intended purpose.

Depending on the fraction of crushed rubber used, it is possible to produce a coating with a different texture.

Material characteristics

The technological process of manufacturing rubber paving slabs for the yard is based on the recycling of old unnecessary car tires. Used tires are freed from the cord, and then crushed, getting pieces of various sizes (fractions). In special mixers, rubber crumb is mixed with a polyurethane adhesive, adding voluminous highly resistant pigments. Then it is poured into molds, pressed (cold or hot) and dried in ovens.

The material stands out for its advantages - environmental friendliness, durability, low cost and ease of installation.

When deciding how to cover the courtyard of a private house, as well as paths and paths in the adjacent area, you should take into account a number of positive characteristics of rubber material:

- abrasion resistance;

- density of the order of 850-930 cm / m3;

- high strength;

- ease of installation and repair work;

- chemical and biological resistance;

- injury safety (since it has a non-slip surface);

- aesthetics, thanks to a large selection of colors and textures;

- long service life (from 10 to 50 years);

- high shock-absorbing properties;

- the ability to easily withstand sudden temperature changes (-45... + 50 ° C);

- non-fading under the influence of ultraviolet radiation;

- frost resistance (at least 300 cycles);

- non-slippery surface (ice formed in winter easily cracks);

- democratic cost;

- good moisture absorption and quick removal of moisture (no puddles remain);

- ease of care;

- light weight and easy transportation (it is very difficult to accidentally break);

- environmental friendliness;

- non-toxicity and safety.

Note! The main disadvantage of rubber tiles is fire hazard. The material is quite flammable, so it should not be laid in a barbecue area, near a fireplace or barbecue, where there is an open fire.

Such a coating can easily withstand heat and frost.

Rubber seamless crumb coating, self-leveling

It is possible to cover the patio or rubber garden paths with a seamless continuous covering. It is laid according to the same principle as self-leveling floors. To prepare the working mixture, rubber crumb is used (the grain size may be different), sold by weights or packaged, and a liquid binder base, as well as various colors (coloring pigments).

Most often, such a base is used when decorating garden paths, in street garages, in parking lots, children's or sports grounds, in an open courtyard.

A thoroughly mixed composition is applied to a previously prepared, degreased and well-dried surface, evenly distributed and leveled, then rolled and lightly tamped. In a day, when the coating dries out, you can already use it.

There is a self-leveling compound that is spread and leveled with a roller.

The self-leveling rubber floor has no joints that you can accidentally catch on. The absence of seams greatly facilitates the cleaning process, since the dirt does not get clogged anywhere. It is important to make a jointless rubber coating on sites with a complex configuration (near the pool, on porch, steps, winding paths in the garden, etc.), where square tiles are good to lay quite hard.

The tile can have various shapes and configurations that imitate the sidewalk option.

Important! To obtain a high-quality rubber seamless coating, it is necessary to mix the working composition very thoroughly.

Yard decoration can be done with roll or tile materials.

Decorative laying of tile material in the yard

Rubber tile material offers two options for laying:

- on compacted soil;

- on a solid base.

You can create a unique pattern from rubber tiles in the yard.

It is preferable to place rubber tiles for garden paths directly on the ground. A coating is selected from 3 to 8 cm thick with special connecting sleeves that allow the elements to be fixed to each other.

For the yard or paths, rectangular or square options are often chosen.

The technology of work is as follows:

- Sod with grass and the upper soil layer are removed, forming a groove 15-25 cm deep.

- Thoroughly tamp the base of the resulting "pit".

- Crushed stone is poured (5-10 cm).

- A sand pillow (5-7 cm) is laid on top.

- Align and tamp well again.

- Lay out the tiles, compacting each with a rubber hammer. There is no need to provide a slope for water drainage, since the liquid will go into the ground through the seams.

- The joints and crevices are filled with sand.

- You can use the coating immediately.

The colors of the coating can also be very diverse - from classic to bright shades.

Important! If necessary, install enclosing curbs. It is better to do this in advance at the preparation stage.

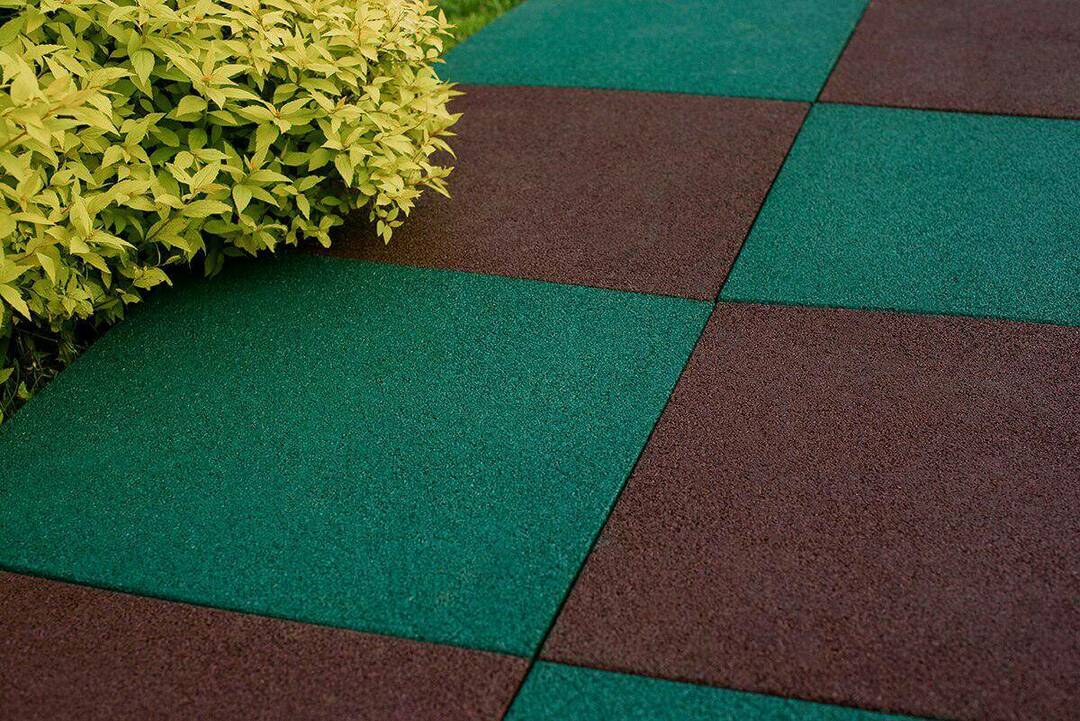

The most popular are green and burgundy shades.

A rubber track for a summer residence is allowed to be mounted on a solid, usually already existing wooden, concrete or asphalt base. You can use thinner tiles - from 2 cm. Works are carried out only in dry weather. The air temperature should be within + 10... + 20 ° C, and the humidity should be about 70%.

The surface of the rubber coating can be easily cleaned with running water from a hose from almost any kind of contamination.

The algorithm of actions is as follows:

- The surface is cleaned of debris, all irregularities and defects are removed, the cracks are covered.

- Cover with a primer. You can use polyurethane glue diluted in half with turpentine or any solvent (acetone).

- Using a spatula, apply a two-component polyurethane glue or a special mastic (rubber-bitumen). Align with a roller.

- Lay out the tiles, pressing them with effort against the base and leaving as little gaps as possible between the elements. The rubber blade can be easily cut into the desired size with a jigsaw, hacksaw or knife (sharp).

- Tap with a mallet (rubber mallet), removing air bubbles.

- A slope of 2-3 ° is required to drain rain and melt water.

- It is permissible to walk to the laid out area in two days, when the glue is completely dry.

Covering the yard with rubber tiles makes the atmosphere on the site as environmentally friendly and natural as possible.

You can lay out various patterns or ornaments from tiles of different colors (herringbone, paving stones, with an offset, diagonally, etc.). It is advisable to first lay out all the elements in the desired order, creating a sketch, but not fastening them together.

Competently using the rubber coating, you can decorate the courtyard of a private house in an unusual and practical way. Subject to the installation technology and the correct selection, the tile material will last for many years.

The flooring made of rubber material will perform not only a functional role, but will also become a decorative decoration of the site.

VIDEO: Laying rubber crumb covering in the country.

50 options for rubber coating of the courtyard of a private house: