Viscoelastic polyurethane foam (PUF) is obtained from polyurethane by saturating it with gas bubbles. Manufacturing is the mixing of components followed by a chemical reaction.

What is Elastic Polyurethane Foam

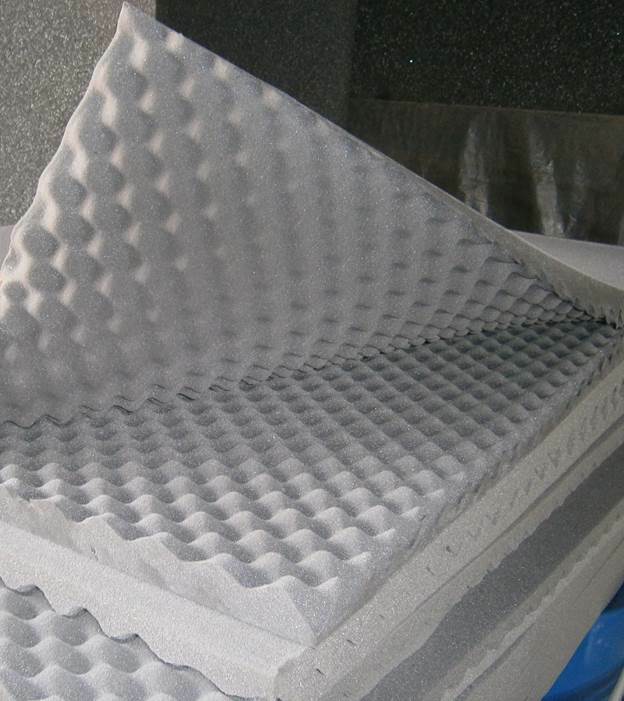

Flexible polyurethane foam is versatile. It is used for thermal insulation and waterproofing of buildings and structures, for the production of furniture and household items. It consists of polyurethane filled with many bubbles. Due to this, thermal conductivity is reduced and noise insulation qualities are improved.

Elastic soft polyurethane foam is known to people as foam rubber. They owe his appearance to the German scientist Bayer. He worked on the study of polymers and as a result of experiments, he obtained a soft substance consisting of 90% gas bubbles. After hardening, it retained its softness and acquired elasticity. In Germany, the mass production of polyurethane saturated with gas bubbles began in the 50s of the 20th century, and 10 years later it began to be massively used in the USSR.

[adinserter block = "9 ″] [adinserter block =" 20 ″]

The production method is simple, it does not require large financial, labor or time costs. Therefore, the material is available. It is used to make sponges for shoes, furniture and build houses.

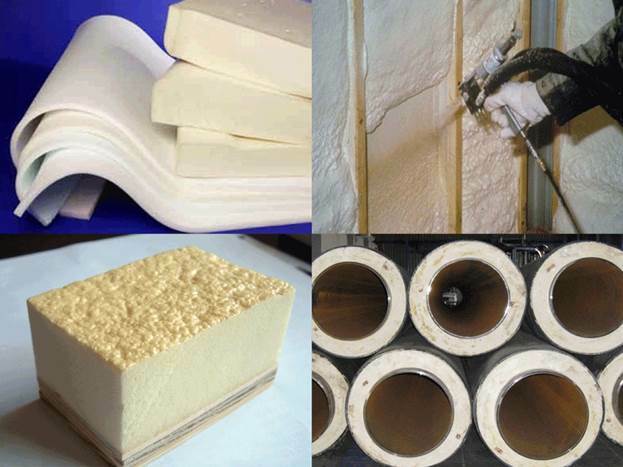

During the production process, the company mixes 2 types of chemical liquids (isocyanate and polyol). They enter into a reaction, during the course of which they release gas. As a result, the material foams and its volume increases several times. After that, the mass quickly hardens, forming a finished product. Depending on the production method, PU foam takes one of the forms. Existing types:

- block;

- molded;

- roll;

- sheet.

Block foams freely, and molded polyurethane foam is poured into molds. Both species have identical properties, but their lifespan will be different. Molded products are durable. Manufacturing of products is carried out by one of the methods: continuous or cellular. In the first case, objects of great length are produced, and in the second, the mass is poured into molds of a given size.

Composition and characteristics of polyurethane foam

The permissible load for various elastic polyurethane foam will depend on the stiffness (from 5 to 40 kg / m3). The characteristics and markings of different products are presented in the table:

| Marking | View | Permissible load, kg / cm2 |

| ST | Standard | 60–100 |

| HL | Hard | 80–120 |

| Hs | Soft | 60–120 |

| EL | High rigidity | 60–100 |

| HR | Highly elastic | 100–120 |

| CMHR | Special purpose | 100–120 |

Important! The characteristics of polyurethane foam vary depending on the composition of the hardening conditions. For example, rigid polyurethane foam contains flame retardant additives. They increase the density to 30–86 kg / cm3reducing elasticity.

[adinserter block = "10 ″] [adinserter block =" 21 ″]

Therefore, polyurethane foam is used in the construction of houses as a heat-insulating material or waterproofing.

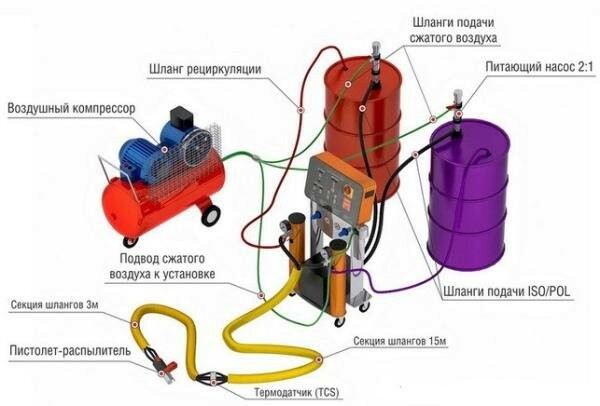

Sometimes it is advisable not to use a finished product, but to use equipment for spraying and mixing substances on the site. The builders combine the components in predetermined proportions and spray the resulting mass on the structure. At the same time, foamed polyurethane foam is not inferior in strength and thermal insulation characteristics to products manufactured at the factory. Technical characteristics of any kind of PPU:

- Volumetric weight is 45-60 kg / m3. The material is ultra-light, it practically does not load the structure.

- The compressive strength is 0.46 MPa. At the same time, the PU foam is deformed only by 10%.

- Thermal conductivity is 0.021 W / m * K.

- PPU can withstand up to 1000 freezing cycles. The durability of polyurethane foam increases when used in cold conditions.

- Water absorption is only 2%, the material is not saturated with water and does not lose its thermal insulation characteristics even in humid conditions.

- Vapor permeability 0.001 mg / m * h * Pa provides almost complete vapor barrier.

- The service life reaches 50 years.

- Non-toxic, it does not emit harmful substances and dust, does not smell, can be used in the food industry (for example, to insulate refrigerators).

The material has gained wide popularity due to its ease of use, strength and durability. It is used in almost all spheres of human life. Each house has several products made of polyurethane foam.

Advantages and disadvantages

[adinserter block = "13"]

The popularity of flexible polyurethane foam is due to its advantages:

- Good adhesion to the surface simplifies the installation process. The material can be either laid with slabs or sprayed onto any surface.

- There is no need to use fasteners to lay the polyurethane foam.

- Seamless laying of the heat-insulating layer allows to eliminate cold bridges in the structure.

- Manufacturers produce molded polyurethane foam of any configuration for different purposes.

- The material does not react with acids, is not afraid of water.

- Fungus and mold do not form on the surface, PU foam is not afraid of insects and rodents.

- Products can function normally at temperatures from -200 to + 200 ° C.

The advantage of liquid sprayed polyurethane foam is crack filling. It can be used to insulate any object or complex architectural forms. At the same time, after hardening, the sprayed PUF is not inferior to the classical one.

Viscoelastic polyurethane foam has several disadvantages. When creating a project, it is necessary to provide for the protection of polyurethane foam from sunlight, ultraviolet light destroys the material. Sprayed polyurethane foam should only be applied to a prepared, dry and warm surface. This causes difficulties when performing work in the winter. Therefore, it is recommended to use the material only in summer or to resort to additional heating of the surfaces.

Ready-made polyurethane foam is absolutely safe for humans, but when sprayed, it emits harmful substances, and can lead to health problems. Therefore, builders need to be careful when using polyurethane foam. As the temperature rises, the material begins to smolder and the structure collapses.

Areas of use of polyurethane foam

[adinserter block = "11"]

Viscoelastic polyurethane foam has gained wide popularity in construction, furniture production and the manufacture of various household items. With its help, many works are performed:

- Corrosion protection of metal structures and pipes.

- Creation of thermal insulation.

- Memory foam material is used for the production of mattresses and pillows.

- Highly resilient soft polyurethane foam is used to create comfortable pieces of furniture.

Polyurethane foam is an indispensable element for the production of many products. It is widely used for thermal insulation and noise protection. The material has gained great popularity and firmly entered the life of a person. Each house has several items made of polyurethane foam.

Cost of flexible polyurethane foam

The price of flexible polyurethane foam depends on its type and characteristics. The average cost of a system of components for spraying polyurethane foam is from 20 to 100 thousand rubles per package weighing from 20 to 80 kg.

Simple sprayed polyurethane foam is used to create thermal insulation in technical and residential premises. A soundproofing layer is created from the slabs. Materials with unusual characteristics have found applications in the furniture industry. They are essential for the production of comfortable pieces of furniture.

What is the price of elastic polyurethane foam, hardness 4 kpa, density 0.028 g / s.cub