In 1999, a new insulation for pipes appeared on the market, which managed to overtake all materials that had existed up to this point in popularity. Thanks to its flexibility and functionality, Energoflex has become a leader in pipeline insulation. The substance is based on polyethylene, which is pre-foamed with gas. Consider what Energoflex is as a heater for pipes and a table of its dimensions.

Specifications

The material is made from environmentally friendly components that do not pose a threat to humans. They do not release any toxins and are not a place for bacteria to accumulate.

Important! Energoflex turned out to be very resistant to the effects of various media, including chemical and physical effects.

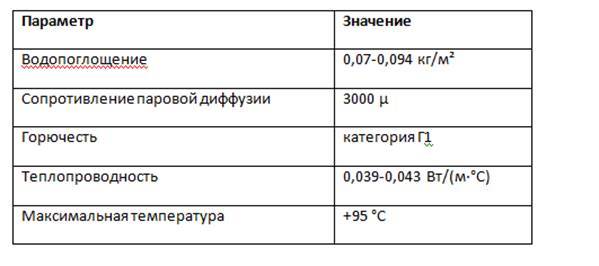

The description of the energy flex and its characteristics are presented in the table below:

Energoflex, whose technical characteristics are indicated above, is very resistant to biological threats, representing a rather unfavorable environment for the development of bacteria and decay. During operation, the material does not change its shape and size even under strong external influence. Separately, it is worth noting the good soundproofing qualities of the material.

The substance is supplied in the form of a soft, elastic material that is reasonably light in weight. Even one worker can handle the installation of insulation.

Energoflex Super tubes and rolls

The most common type of insulation, which is suitable for almost any work. It is usually supplied in the form of Energoflex super tubes with a length of 1 to 2 meters. The diameter varies from 15 to 42 mm. The wall thickness always remains the same: 9 mm.

If it is necessary to insulate areas with a large diameter, you can purchase the material in the form of a roll. This will allow you not to limit yourself while working. Such materials are fixed to the surface with the help of a special glue, which also serves as thermal insulation for the insulation of pipelines. The table below shows the main characteristics of this variety:

Energoflex Acoustic Tubes

A special shape that has been specially created with an emphasis on improving sound insulation. Such materials are used to get rid of extraneous sounds in sewer mines, etc. All this is possible thanks to a specially designed wave-shaped surface that reflects sound waves.

Energoflex Acoustic specifications:

Energoflex Black Star tubes and rolls

A product designed for thermal insulation of copper parts. It has a number of advantages that allow it to coexist with copper more efficiently. The material is excellent at absorbing moisture and has a high level of diffusion resistance. This completely removes condensation, which usually becomes the main cause of rust.

Energoflex Black Star characteristics:

Insulation size table

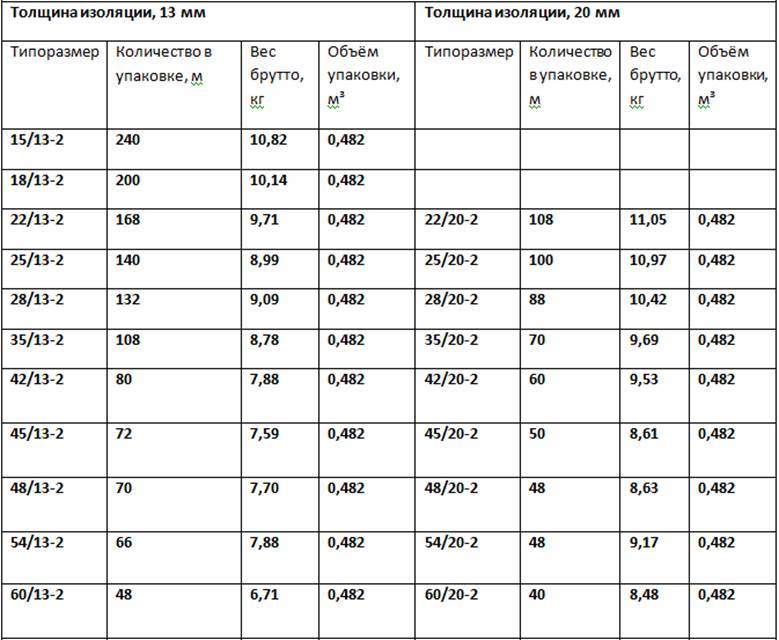

The use of energoflex is available both for interior spaces and for facades. Below is a table of insulation sizes, which describes the main characteristics of materials with an inner diameter of 6 - 160 mm. The wall thickness is also taken into account, which varies from 6 to 20 mm. Another important indicator is the length that is supplied. You can find items from 1.2 to 11 meters in length. Table of characteristics of material Energoflex Super 2 m long:

As you can see, the choice is quite large. There are heaters of exactly the sizes that are needed.

Purpose of application

Energoflex is used for various purposes, in each of which it manifests itself as a very thoughtful and effective material. Let's take a look at the known uses.

Reduced heat loss

Energoflex is thermal insulation, which means that this is precisely its function. When applied, the material allows for a long time to maintain the temperature that is necessary for the transfer liquid or gas. Energy losses are reduced, which makes it possible to reduce the consumption of all resources that are designed to heat water. So heating and hot water supply will be very efficient.

During work on thermal insulation, it is important to remember on your own that only those pipes that are not located directly in the heated room need to be protected. So all heating fittings in the basement or outside can be insulated. The rule is due to the fact that unprotected pipes heat the rooms by transferring heat to the environment.

Insulation of pipes that are part of hot water supply or heating systems seems to be quite logical. But is it necessary to insulate the sewer taps? To answer this question, it is necessary to take into account exactly where these pipes pass. If they are not buried deep enough and touch the area of freezing of the soil, then insulation must be done. Only in this case it will be possible to achieve full provision of all the amenities necessary for life.

Important! It is recommended to carry out frost protection not only with thermal insulation, but also with a special heating cable.

Condensation control

Condensation can bring home owners no less problems than freezing of the pipeline. It appears to be the result of an increase in air humidity with a change in temperature. Small droplets begin to accumulate in water supply areas, which can lead to corrosion or material destruction. This is exactly what happens with many cold water pipes in summer. The temperature difference inside and outside does not pass without leaving a trace, but is transformed into drops of water.

In addition to corrosion, other unpleasant consequences can also appear. For example, puddles under pipes that form due to prolonged condensation formation. Such operation significantly reduces the service life of products, making them more vulnerable to other environmental influences.

To avoid all the unpleasant consequences of the formation of condensation, it is recommended that all cold water supply pipes be insulated with heat-insulating materials. It is best to use Energoflex insulation. Installation may additionally require polypropylene fittings.

Noise protection

Replacing the pipes in the sewage system from cast iron to plastic ones led to the appearance of a booming sound, which was accompanied by the operation of all drainage systems. And this sound was able to cause quite a lot of inconvenience to all the inhabitants of the houses. The situation was analyzed and experts came to not the most comforting conclusions. Since the plastic sewer was made of pipes with a smaller wall thickness, and the material itself had a much lower density compared to cast iron, the sound propagates much faster. At the same time, all the noise is repeatedly reflected from the surface of the pipes, constantly increasing the volume. At the exit, we get a loud hum, which can easily disrupt the quiet life in the house.

In order to reduce the effect of noise on life, it is recommended to use Energoflex heaters. The company offers special materials with improved noise insulation properties. Also effective in this case is the usual roll insulation, attached to the pipes with glue. Sometimes the manufacturer pre-applies glue to one of the surfaces, so the builder only needs to properly fix the material to the pipe.

Material advantages

It is not for nothing that Energoflex insulation takes first places in the list of the most effective heat-insulating materials for pipes. It has a number of advantages that make it stand out from its peers. But do not forget about the main functions that any insulation performs:

- Protection of the pipe against corrosion, which is a consequence of the harmful effects of external factors (condensation, rain, precipitation, etc.);

- Temperature regulation in winter. It is necessary in order to avoid freezing of the water supply system with subsequent rupture due to the expansion of ice.

- Reducing heat loss in parts of heat supply systems that are located outside.

But in addition to these standard functions, Energoflex surprises with a number of advantages that are not characteristic of many heaters:

- resistance to various chemical influences;

- prevents the development of bacteria;

- excellent strength indicators, which eliminate the need for additional pipe protection;

- ease of installation, which does not require special knowledge and skills;

- harmless to the environment;

- safety for human health;

- lack of toxins;

- high level of corrosion protection;

- high flammability class, minimizing the likelihood of ignition;

- the ability to reduce energy and resource consumption;

- maintaining the required temperature in the pipes.

Important! Energoflex has a fairly wide operating temperature range. The material functions perfectly at temperatures from -40 to 100 degrees. At the same time, all properties and characteristics remain at the same level.

One of the main advantages seems to be a wide range of materials for various needs. From the manufacturer, you can find insulation for insulating water supply pipes, sewers, heating units or ventilation. The required diameter of Energoflex pipes is always available.