Houses built from lightweight aggregate concrete blocks are individually Budget embodiment construction.

This is due to the low cost and the material strength. Construction is much easier to brick - built for their use arrayed foundations. Place the blocks can be their own hands. Often, however, already in the first winter, and the owners are thinking about, the walls are not very good "hold" heat. Thermal insulation of walls made of lightweight aggregate concrete block wall from the inside or outside of it becomes a solution.

Features of the blocks and the need for insulation

The apparent at first glance "warm", expanded clay in fact such is not - thermal conductivity depending on the amount of filler (expanded clay) ranges from 0.15 to 0.45 W / mGrad. From this perspective, in various regions of the country according to GOST wall thickness is from 40 to 80 cm. Talk about saving is not necessary.

Important! Products with low thermal conductivity containing a higher percentage expanded clay, are fragile and unstable. To build houses higher than two floors are prohibited.

The porous structure contributes to the high heat transfer and water absorption (50%), if the construction is not protected from exposure to climatic conditions.

Thus, the house of the blocks should be warm. Among the advantages of the material point to the lack of shrinkage - to insulate the wall can immediately after construction.

ways of warming

Well, if the owner is thinking about home insulation even at the design stage. It broadens the choice of insulation and methods of its application.

There are three approaches to thermal insulation of buildings:

- Insulation of masonry. In this case, the heat insulator is laid between the carrier and the facade (surfacing) walls.

- Installing insulation layer on the inner wall surface when finishing or during overhaul facilities.

- External mounting insulation on a wall of lightweight aggregate concrete blocks.

Warming during the construction phase

Blocks - unattractive option and the outer wall is left without finishing rare. The clutch outer layer of a finishing brick can be combined with warming. In this case, the thermal insulation is placed between the carrier and the decorative part of the masonry.

For thermal insulation is used:

- expanded clay;

- Expanded polystyrene;

- basalt wool;

- Foamed polyurethane.

Expanded clay - natural material obtained by sintering of specific types of clay. No additives in the manufacture is not applicable. Material under construction just poured into the space between the walls.

The benefits include environmental friendliness and low price. Among the shortcomings - not the best performance of thermal conductivity and hygroscopic.

Styrofoam for construction is of two kinds. Foam - known to all foam and extruded - a material known under the names Penoplex, Penoplex et al.

Thermal conductivity performance of these materials are the same, but the price of the latter is 2-3 times higher. However, penoplex laying inside the walls rarely used since closed from the weather site, any advantages he has.

Mounting plates does not cause difficulties - they simply put between the bricks.

Material environmentally friendly and nonflammable. Time zamozatuhaniya foam after exposure ceased open fire - 4 seconds. Poison of styrene foam plates is released during heating to 80aboutWith that it is possible only in case of fire. However, the heater is in the "packed" form, so it is safe.

Another option is the use of foam - filling of cavities granules. This is the same foam, but not in the plates as well as balls (loose). The price of pellets 2000 r. per cubic meter.

It is worth noting that the foamed polystyrene produce 3 types of differing density PSB-15, 25, 35. The numbers in the labeling indicate approximate weight of a cubic meter of material. Price depends on the density - density 15 1500 rubles and 3900 rubles. to 35 kg / m3. Producing a foam thickness of 10 to 200 mm. In retail more common material thickness of 30, 40, 50 and 100 mm. However, the manufacturer can order plates of any thickness.

Important! The foam density with the index 15 kg / m3 can not carry the load, it can not be plastered, but as an inner layer in the laying of it fits perfectly.

Penoplex produce a specific weight of 35 to 80 kg / m3. Price extruded polystyrene - 4500 p /3But as mezhkirpichnogo advantages layer and it has rarely been used.

Basalt wool - modern insulation. Products produced by sintering a rock formation with the addition of fillers. Environmentally friendly and useful properties make stone wool insulation popular. Is produced in the form of slabs with a specific weight of 30 to 200 kg / m3. Insulating properties similar to foam, but wool is vapor permeable - the wall will "breathe." When heated, some of the products may produce phenol and formaldehyde, but the application within the sealed walls will not affect the health of residents. Also as in foam poisonous substances occurs under heating. Installation is laying between layers of bricks.

Another possibility to insulate masonry - use polyurethane foam. Material is introduced between the carrier and the front wall through the bores, and after solidification is similar to the adhesive foam. The method is rarely used due to the high cost - need to use special equipment. Make insulation alone is impossible.

The cost of polyurethane foam sheets is high, so the financial benefits for the use of it is not.

The advantage of the Mother - the lowest thermal conductivity, but the cost negates all the advantages.

Comparative table for laying insulation between the walls.

| Material | Characteristics | ||

| Thermal conductivity, W / (m * K) | Density, kg / m3 | Price, m3 | |

| expanded clay aggregate | 0,1-0,18 | 200-400, depending on the fraction | 1300-2500, the larger the fraction, the cheaper |

| Foam PSB-S-15 | 0,04 | 11-12 | 1500 |

| Styrofoam pellets | 0,045 | 9-12 | 2000 |

| Penoplex | 0,032-0,038 | 35-70 | 4800 |

| Stone wool | 0,035-0,04 | 35-200 | 1700-5200 depending on the density |

| Polyurethane | 0,019-0,03 | 50-300 | 9000-16000, The average price for a layer of insulation 50 mm - 500-1600 rubles / m2 |

Thermal insulation inside

Wall insulation from inside the house - a very undesirable option. When installing insulation inside the building dew point is displaced from the walls of the room, it is shown "thermos effect". On the walls, condensation can form, decoration, such as wallpapers, soak and come unstuck on the walls there is a mold fungus. Repeated cycles of freezing units lead to their destruction - 50-220 manufacturer provided such freeze-thaw cycles. After reconstruction, the thickness of insulation and finishing decrease useful space area.

It justified the use of an internal insulation in the following cases:

- Completed construction and exterior decoration;

- the house is rarely used, heating during the absence of the owners turned off. When connecting the heaters warmed up the room quickly, as the brick walls are not warmed up. Internal insulation - the best choice for villas and guest houses;

- make insulation of external walls is not possible - for example, housing, building of blocks located in an apartment building.

Other advantages of this method are:

- possibility of carrying out work at any time of the year;

- no need to install scaffolding for work at height.

materials

As an internal heater selected materials with low moisture absorption. For instance, not approach the plate of mineral wool.

When choosing the technology necessary to provide gaps between the insulation and finishing. For example, gypsum board or MDF panels desirably mounted on a frame made of galvanized profile.

As the insulation is recommended to use a foam or extruded polystyrene, rolled materials based on polyethylene, foamed polyethylene foil.

The properties of the foam and Penoplex described above.

Polyethylene foil weighs to 60 kg / m3, the thermal conductivity is comparable to the foam, about 0.03 W / (m * K). The advantage lies in its properties do not absorb moisture and ease of installation in the home. Slightly worse performance without foil layer.

Installation inside thermal insulation

Make insulation the inner surface of the walls of the forces of any master who knows how to handle the appliance.

The algorithm is:

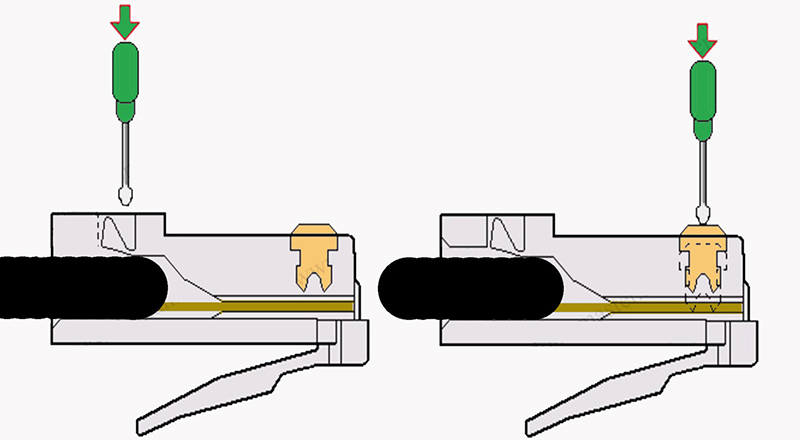

- On the surface of a wall stacked foil insulation, fixing it dowels. It is important that the cap, dowel-nails were wide - type "fungus."

Important! Mounting foam after setting the framework for finishing.

- Is attached to the wall of the crate galvanized profile for finishing drywall or siding various modifications. The horizontal distance and vertical distance between the beams is selected based on the finishing material. For plasterboard - to fit the paper, for siding, plastic or MDF panels is not more than 50-60 cm between the horizontal profiles. foam sheets should be included between the profiles "in tension".

- When mounting lath provide a gap of 1-2 cm to the insulation material after the installation of the finish.

- Carry out the installation of drywall or siding.

- Completing finish plaster surface. If using drywall corners or glued on MDF panels.

Important! When using roll material, you need to make on-site overlaps abutting the exterior walls to the ceiling and interior partitions.

Exterior insulation

Insulate the facades of houses - the best of the options:

- After finishing the building takes on well-groomed appearance;

- The dew point is shifted closer to the outer side of the block;

- Perhaps the use of all types of insulation without the risk of harm to the health of the residents;

- The interiors do not lose useful space;

The disadvantages include:

- Additional costs for steam and waterproofing;

- Inability to work in the cold season.

Materials for thermal insulation of external walls

About the quality and characteristics of different types of polystyrene, basalt wool and polyurethane described above. Often used for insulation of mineral or glass wool, formed in individual sheets or packed in rolls.

The main advantage of these materials is an affordable price. However, it is worth saving. Mineral wool has a high index of water absorption, slozhivaetsya and thins in poor waterproofing, losing part of the insulating properties.

The drawback of glass is difficult to install - it is necessary to use a skin and respiratory protective equipment because of small void fraction, which shatters even when touching the mat.

Thermal conductivity performance materials are inferior stone wool, also lose some of the properties over time.

Types of external insulation

There are two fundamentally different ways of outer insulation walls:

- Wet. Sheets of insulation glued to walls and plaster. During operation, thermal insulation is under the influence of external weather conditions.

- Dry method or ventilated facade insulation and waterproofing involves finishing of panel material.

wet process

This type of insulation involves the use of foam, Penoplex, stone wool.

The algorithm is:

- Line the walls, closing up the recess, the seams between the blocks, removing accretions masonry mixture.

- Line the walls with plaster with low-quality masonry, surface treated with primer deep penetration for external works.

- On the surface of the insulation sheet glue is applied, selecting the type based on the manufacturer's recommendations.

Important! Foam with density 15 kg / m3 is not suitable for wet insulation - it is not designed for the load. Use material labeled DPM-S-25, suggesting plastering.

- Sheets adhered to the wall surface. After drying the solution further strengthen the heater plugs with wide heads.

- Adhesive plaster applied thinly to the heater.

- On the surface of the sheet stack and pritaplivayut the initial layer of adhesive plaster for external use of the net.

- Carry out the finish plaster, choosing mixtures for external use, or, for example, a mixture of "pitted".

- After drying the stained surface façade paints.

dry method

Such warming would require sheathing installation, use of steam and waterproofing membranes.

The procedure works:

- Sealed joints in the masonry, clean the pick remnants of masonry mixture.

- Reinforce vapor barrier layer on the wall of the membrane.

- Mount frame based on the size of sheets and insulation finishing material.

- Insulation sheets laid between the crate.

- Nailed to the frame waterproofing membrane using slats 10-20 mm thickness - they provide clearance for the facade decoration.

- Mount finishing.

In the last year, a new type of building material for facades - with insulation tiles, consisting of two layers.

The outer layer is made of concrete or plastic - it is protective and decorative function, simulating wood or stone. The inner layer - foam. Two "tightly" material glued together.

Installation is carried out on a flat surface, gluing tiles and fixing dowels. The characteristics of the material close to the polystyrene, but does not need external decoration. The price for this tile is still quite high, from 500 r / m2, which is caused by small production volumes.

Expanded clay walls in the construction of private houses - cost-effective solution for individual developers. However, the house will acquire a finished look, but inside will be more comfortable after the insulation. An additional advantage would be a significant reduction in heating costs, which "whacks" costs over several years. Installation of the thermal insulation of force to anyone and a minimal amount of construction skills.