The topic of today's conversation will be cold forging, or the shaping of metal without heating. This may not be very useful knowledge for most home craftsmen, but it can come in handy. Moreover, such work can be compared to art. The author of the YouTube channel presents his vision of cold forging methods Maxim. And today we will talk about how to twist a profile pipe into a spiral, bend a regular pipe at 90 ° and at the same time not jam the metal.

Read in the article

- 1 Twisting the profile pipe into a tight spiral

- 1.1 Preparing the profile pipe for twisting

- 2 Twisting the profile pipe into a torsion bar

- 3 Cutting off excess parts of the profile pipe

- 4 Another of the secrets of cold forging

- 5 Summing up

Twisting the profile pipe into a tight spiral

For twisting various steel elements into a spiral, there is a special machine called a torsion bar. It can be electrical or mechanical. At the same time, craftsmen assemble such devices with their own hands. By analogy with it, finished products of a twisted shape began to be called the same. But twisting a rod into a spiral is one thing, it does not jam. But what if it is necessary to twist a profile pipe into a tight torsion bar, inside of which there is a void?

In order for the spiral to turn out even, you need a piece of a thin tube or rod, which will fit freely inside the profile pipe.

Preparing the profile pipe for twisting

In order to "charge" a profile pipe into a torsion bar, you will need to make two plugs on it from a steel bar of square cross-section with sides of 16 mm. These elements are plugs that will hold the steel tube inside. At the same time, it is they who will allow clamping the profile pipe in the machine. The first plug is placed first.

Next, an insert is lowered into the profile pipe, after which a second plug is installed. The workpiece can now be inserted into the machine.

It remains to fix the workpiece on the machine and turn it on, if it is equipped with a power unit. If not, then you have to work manually.

Twisting the profile pipe into a torsion bar

After turning on the machine, the pipe first twists slightly along its entire length, after which the spiral begins to thicken. However, compaction does not take place simultaneously along the entire length, but starting from the side to which the torque is transmitted. Here the effort is much greater. In the photo example, the seal moves from bottom to top.

It is worth noting here that the thinner the inner insert is, the more force will have to be applied to twist. But at the same time, the spiral will turn out to be denser.

Cutting off excess parts of the profile pipe

After the torsion bar is evenly twisted along its entire length, its edges are cut off so that the product can be used, for example, for decorative purposes. An angle grinder (grinder) with a cutting disc will help in this work.

Do not even try to remove the tube inserted inside. When twisting, it is so strongly clamped on all sides by the edges of the profile pipe that it is useless to take any action to remove it.

Another of the secrets of cold forging

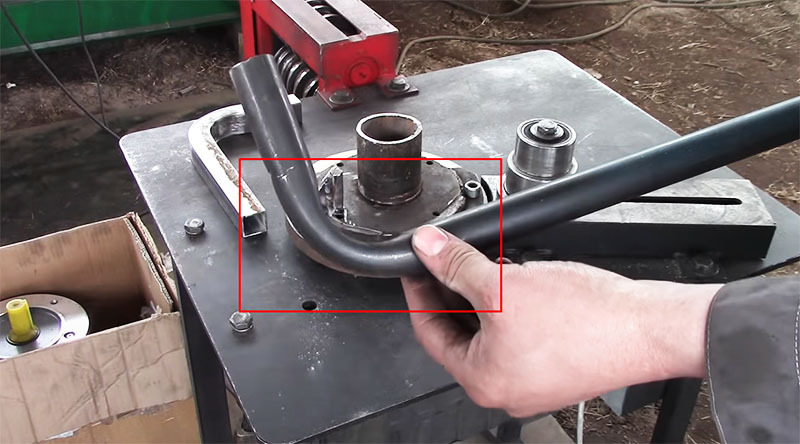

Surely everyone knows what a pipe bender is. Many DIYers install similar equipment in their garage or workshop.

Its problem is that when processing pipes, it can jam them a little. And everything would be fine, but if, for example, a heated towel rail is made, then water should easily pass along these bends. One such point will not spoil the overall picture. And what will be the pressure resistance if water meets such an obstacle on each floor of the riser?

In this case, ordinary sand will help, which must be poured into the bending pipe, and its ends must be muffled. In this case, even a ¾ inch thick pipe bends easily without any folds or breaks. In an example, this can be seen by comparing the results.

No comments, the result speaks for itself.

Summing up

In general, cold forging is quite an exciting experience. Usually, if a person tried to create a masterpiece from metal, and he succeeded, he falls in love with such a work. And these are not empty words. After all, this is real magic - to revive a cold piece of metal, turning the armature into a work of art. In addition, if you do cold forging professionally, there will definitely be no end to those wishing to make beautiful lattices, fences or fencing. In addition, today such handicrafts are very expensive. So, it is worth considering whether to change the sedentary job for a more profitable and interesting one. Indeed, during a pandemic, such a question is very relevant. You decide.

We really hope that today's article did not leave our dear reader indifferent. Perhaps you have questions on the topic, or some points have not been fully clarified. In such a case, you just need to state the problem in the comments below. HouseChief editors will be pleased to highlight all the ambiguities as soon as possible. There you can also discuss today's topic, express your personal opinion about the manufacture of parts for decorative fences and lattices with your own hands. We will be grateful if you rate the article - regardless of its "polarity". And finally, I would like to say the following - take care of yourself, your loved ones and be healthy!