Wing bolts are very often simply irreplaceable in solving various problems. The only problem is that they may not be at hand at the right time, or they have uncomfortable handles that are inconvenient to tighten. Meanwhile, you can make such a bolt in just a couple of minutes from what is at hand.

Read in the article

- 1 What is required to make a bolt with a handle

- 2 How to make a bolt with a plastic handle: step by step

- 3 Wing bolt from a regular chain and other ideas

What is required to make a bolt with a handle

You will see similar bolts in office chairs or other similar furniture, and they are also used as leveling feet. They can be used as a stopper to secure a moving part.

How to make a bolt with a plastic handle: step by step

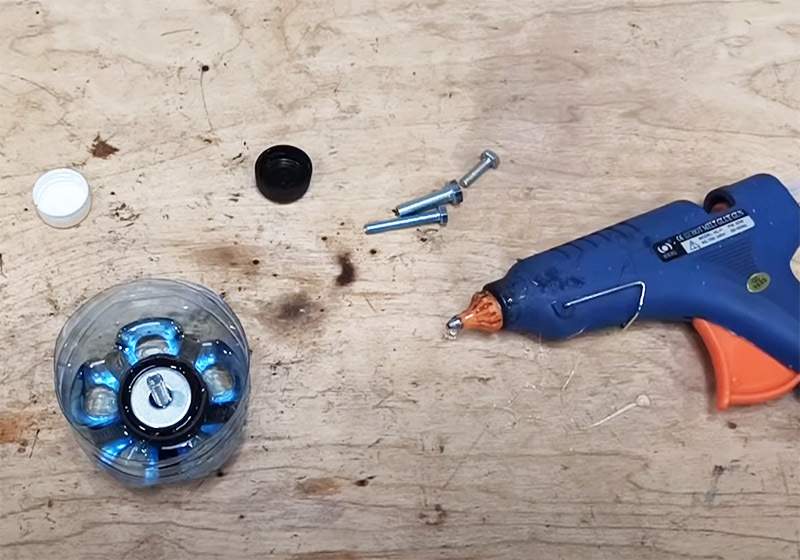

The assembly algorithm is very simple, and all the work will take you no more than a couple of minutes.

To prevent the handle from spinning precisely on the bolt, it is better to cut the threads inside the cover in several places.

As a result, you get a convenient tool for fixing moving parts. There is only one thing to remember: such bolts should not be tightened with great effort, because the hot melt glue may not withstand excessive pressure. But if instead of hot melt glue you use epoxy, then you don't have to worry about the strength of the part. It will take more time to freeze, you will have to wait a couple of days, but in return you will have a strong and durable fastener that will always be at hand.

Some craftsmen offer other options, for example, to melt on the bolt head not with hot melt glue, but with the usual more refractory plastic, which will provide a more reliable fixation. To do this, the bolt is clamped in a drill and at high speeds is carried out with the head over the plastic. Friction heats up the plastic and winds it around the head.

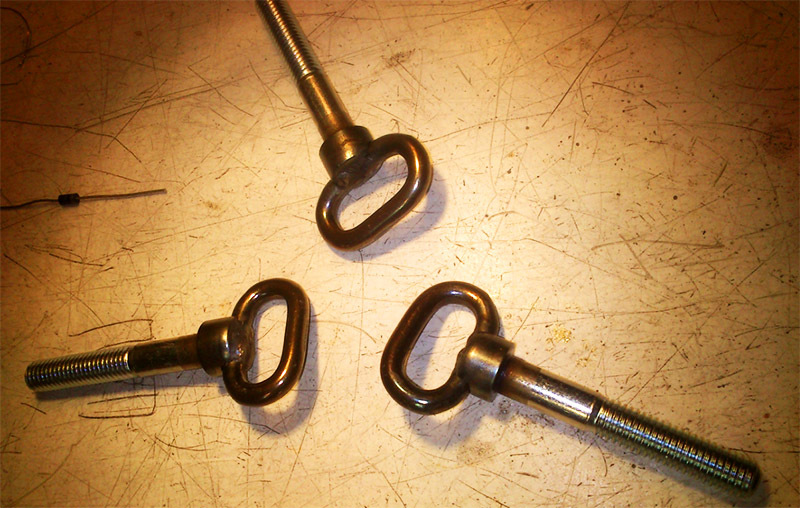

Wing bolt from a regular chain and other ideas

There is another option for solving this problem, which is very popular among DIYers.

There are other options for making such products, some of them are set out in this video:

How do you like this idea? Have you tried making lambs on your own? Share your experience in the comments!