Working on a personal plot or having a small allotment at some distance from home, you have to constantly transport this or that cargo: the grown crop or the collected garbage. A trailer for a walk-behind tractor will help to facilitate work, which you can make with your own hands. To do this, you need to get acquainted with the device of the trolley for the walk-behind tractor, purchase the necessary materials and components, and then get to work.

Read in the article

- 1 Trolley device for walk-behind tractor

- 2 Possible options for a trailer for a walk-behind tractor with photo examples

- 3 PHOTO: avtoromny.clan.su Do-it-yourself trailer for a walk-behind tractor: drawings, materials, manufacturing procedure

- 3.1 Required materials and tools

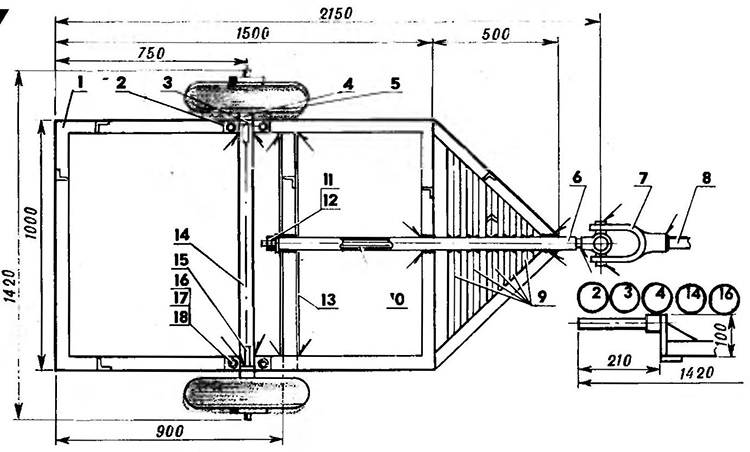

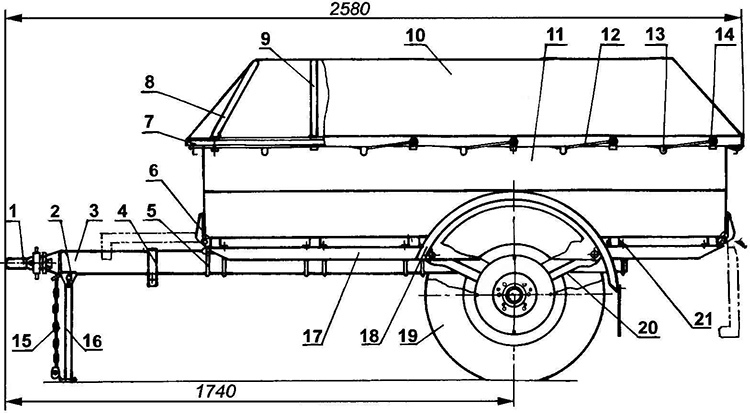

- 3.2 Drawings with dimensions of a trailing device for a do-it-yourself walk-behind tractor

- 4 Making a homemade trailer for a walk-behind tractor

- 4.0.1 PHOTO: a.d-cd.net

- 4.0.2 Chassis

- 4.0.3 Body, frame lining

- 4.0.4 Do-it-yourself brakes on a trailer to a walk-behind tractor: manufacturing procedure

- 4.0.5 Other details

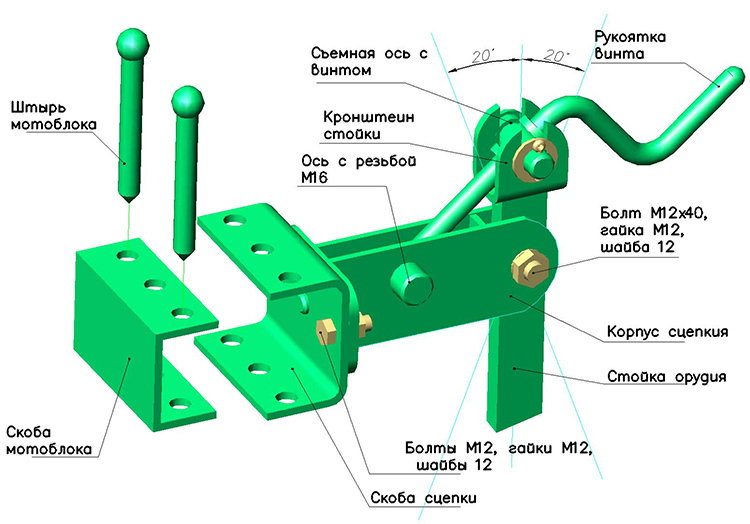

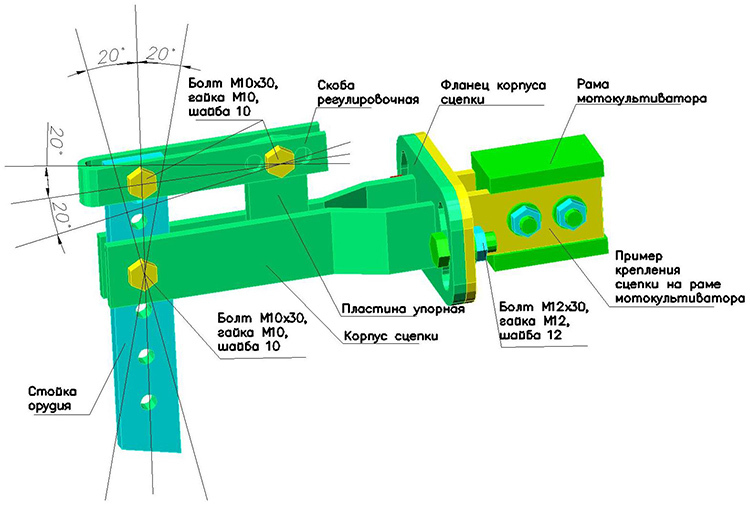

- 5 Self-production of a hitch for a walk-behind tractor

- 5.1 Drawings of a hitch for a walk-behind tractor

- 5.2 How to make a hitch for a walk-behind tractor trailer: an algorithm of actions and video instructions

- 6 The nuances of manufacturing other types of trailers for agricultural machinery

- 6.1 DIY cultivator trailer: manufacturing nuances

- 6.2 How to make a two-axle trailer for a walk-behind tractor: video instruction

- 6.3 Tipper trailer for a walk-behind tractor: design features

Trolley device for walk-behind tractor

When deciding how to make a trolley for a walk-behind tractor with your own hands, you must first decide what kind of cargo will be transported with its help. This will have a serious impact on the design of the manufactured product. Depending on the carrying capacity, trailers are usually divided into devices that allow you to transport:

- up to 70 kg. They have a simple design;

- up to 110 - 120 kg. A universal option. Most commonly used in the household;

- more than 120 kg. They have advanced functionality. They place increased demands on the strength characteristics of the materials used in the manufacture of the bearing element and finishing.

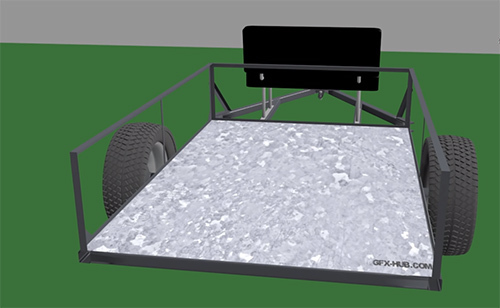

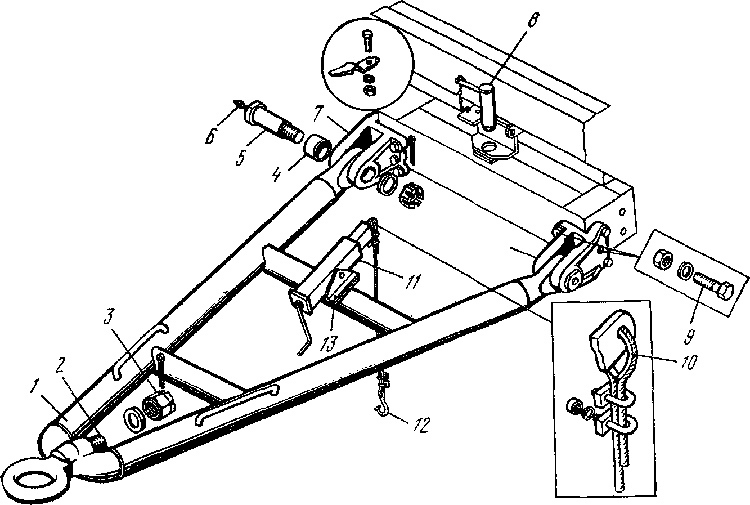

In the most general case, the trolley for walk-behind tractor includes:

- frame that takes the load during operation. For its manufacture, a channel or rolled metal can be used, depending on the required carrying capacity;

- a body into which the transported cargo will be loaded directly;

- hitch or drawbar, with which the trailer is connected to the walk-behind tractor;

- driver's seat. The configuration and size are developed taking into account the physique of the owners;

- steering gear;

- chassis.

Thinking over how to make a cart for a walk-behind tractor with your own hands, you should decide on the number of axles. For a two-axle structure, a hydraulic body tipping drive should be provided. For uniaxial enough manual.

If the carrying capacity of the device exceeds 350 kg, it is worth taking care of the braking system. Otherwise, when descending from a hill, the cart may overturn. In order for the body to remain horizontal after disconnecting from the walk-behind tractor, it is worthwhile to provide stops.

Possible options for a trailer for a walk-behind tractor with photo examples

It can be quite difficult to immediately find the right option for the needs of your family. In this case, it is worth examining the already assembled structures. This will allow you to better understand the design features and, if necessary, make some changes to the design. We offer you to see a photo of motoblocks with a trailer, which you can make with your own hands.

PHOTO: a.d-cd.net

PHOTO: a.d-cd.net PHOTO: a.d-cd.net

PHOTO: a.d-cd.net

PHOTO: koffkindom.ru

PHOTO: koffkindom.ru

PHOTO: avtoromny.clan.suDIY trailer for a walk-behind tractor: drawings, materials, manufacturing procedure

PHOTO: avtoromny.clan.suDIY trailer for a walk-behind tractor: drawings, materials, manufacturing procedure

In order for a do-it-yourself cart for a walk-behind tractor to turn out to be of high quality, you need to find the correct drawings containing all the necessary information and purchase high-quality materials. The list of required materials and tools may differ significantly depending on the carrying capacity and design features of the structure. We offer you to get acquainted with the procedure for making such a product with your own hands, if the price of a trailer for a walk-behind tractor seems too high.

PHOTO: masterbud.dp.ua

PHOTO: masterbud.dp.uaRequired materials and tools

To create a trailing device for a walk-behind tractor with your own hands, you need to prepare:

- welding machine;

- grinder with a set of disks of different sizes;

- measuring tool, including for measuring angles;

- marker or other means for applying markings;

- hammer, chisel, pliers;

- vice, clamps;

- drill with drills of different diameters;

- riveting equipment.

PHOTO: auctions.c.yimg.jp

PHOTO: auctions.c.yimg.jpThe list of materials depends on the characteristics and characteristics of the trailer being manufactured. The frame will require a metal profile, pipes, corners, channel bars. Their size is selected taking into account the requirements of the drawings. For the manufacture of a pallet, a sheet with a thickness of up to 2 mm is taken.

Attention! Various fasteners can be used to connect the elements. If the choice is made in favor of boots and nuts, the equipment for rivets can be discarded.

Wheels for a walk-behind tractor trailer can be of different diameters. Often the choice is made in favor of the wheels of "Zhiguli" or "Moskvich". This design will have good cross-country ability.

PHOTO: media2.24aul.ru

PHOTO: media2.24aul.ruDrawings with dimensions of a trailing device for a do-it-yourself walk-behind tractor

When making a trailer for a walk-behind tractor, do-it-yourself drawings with dimensions.

PHOTO: obinstrumentah.info

PHOTO: obinstrumentah.info PHOTO: prisep.ru

PHOTO: prisep.ru

Making a homemade trailer for a walk-behind tractor

To make a homemade trailer for a walk-behind tractor with your own hands, you should adhere to a certain sequence of actions. We invite you to get to know her.

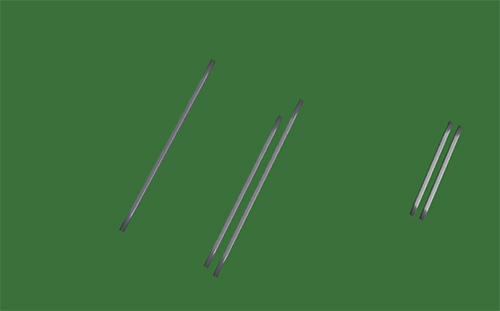

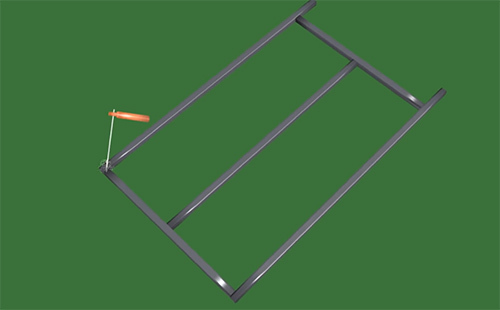

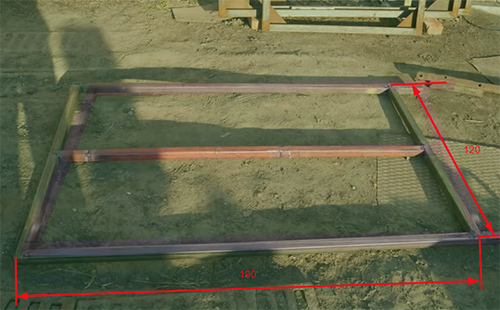

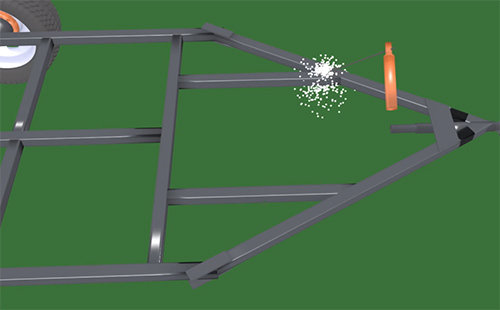

For the manufacture of the frame, rolled metal is taken with a suitable shape and cross-sectional size. The works are performed in the following sequence:

| Illustration | Procedure |

| The rental is cut to size. The number of elements and their parameters depend on the dimensions and carrying capacity of the future body |

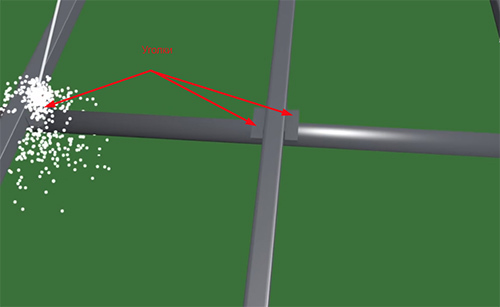

| The prepared segments are welded together, forming a frame with crossbars. Their spatial position is carefully controlled. Particular attention is paid to the corners at which adjacent elements are located |

| The assembled frame is additionally welded around the perimeter, which ensures sufficient strength of the finished structure |

Chassis

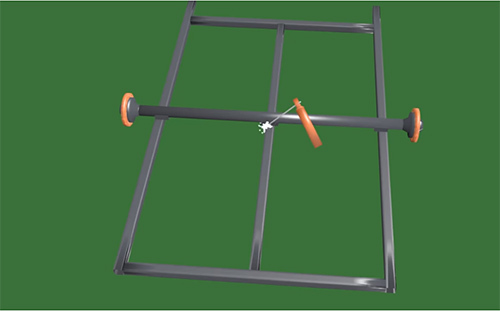

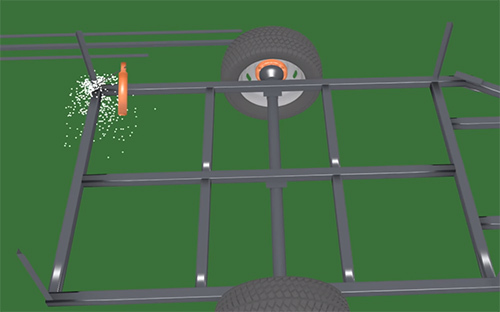

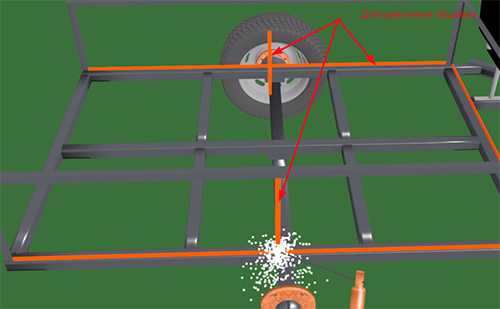

Assembly work for the manufacture of the chassis of a homemade trailer is performed in the following sequence:

| Illustration | Procedure |

| When making do-it-yourself axles for a trailer, half-shafts from "Zhiguli" are welded into the pipe. Channels are welded along the edges and in the center of the pipe, to which the frame will be attached |

| The frame is welded to the beam. For this, the structure is turned over and a welding seam is formed on the reverse side. |

| The structure is turned over. At the points of contact of the frame with the axis, the elements are welded together, having previously installed the corners |

| To further strengthen the frame, the cross members are welded. They are located in accordance with the drawing. |

| Install the wheels. Check their parallelism. Its structure is welded correctly, the wheels will fit correctly |

| The drawbar is welded, if it has not been done earlier |

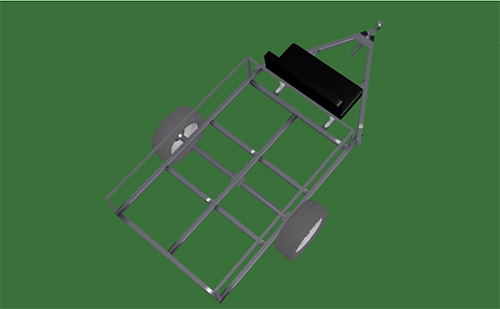

Body, frame lining

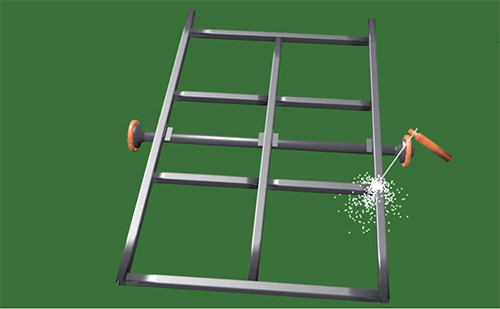

Body shaping is performed in the following sequence:

| Illustration | Procedure |

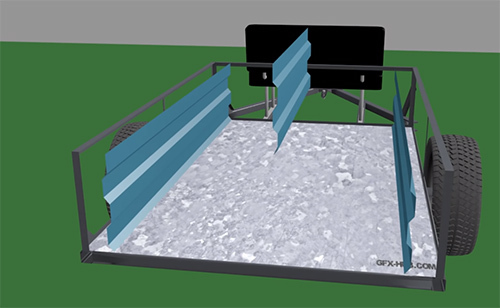

| Vertical posts are welded to the frame. Their height depends on the volume of the manufactured trailer for the walk-behind tractor. On average, their height is 42 cm |

| Vertical posts are interconnected by horizontal elements. The spatial position of each is carefully controlled. If necessary, the seat is welded. The structure is installed assembled |

| Additional elements are welded to the frame to fasten the skin. Provides horizontal and vertical details |

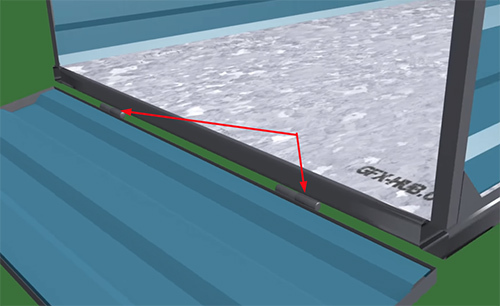

| The pallet is attached. Sheet metal up to 2 mm thick can be used. First, the pallet is grabbed, and then carefully welded around the entire perimeter |

| The sides are installed. For their manufacture, sheet metal or metal profiles are used. |

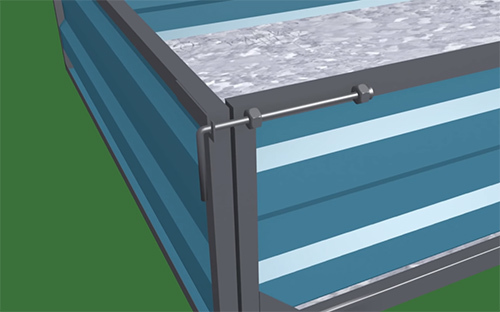

| The tailgate hinges are welded to the frame. The counterpart is welded to the tailgate itself. The element is installed in place |

| A structure is welded to fix the tailgate while driving |

Do-it-yourself brakes on a trailer to a walk-behind tractor: manufacturing procedure

So that the trailer to the walk-behind tractor does not accidentally roll, you should think in time how to make the brakes. If they are available, the safety of the trailed structure will be significantly increased. To make brakes on a trailer for a walk-behind tractor with your own hands, you need to have a traction, cable and drum available. The work is carried out in the following sequence:

- we attach the drum to the hub of one of the wheels;

- weld a piece of pipe to the brake disc;

- we put the mechanism on the axis;

- on the axle we fix the brake pads with a cable. We stretch the latter to the lever, which we install next to the driver's seat.

Attention! The brake is usually mounted on one wheel. The force it generates is sufficient to stop the trailer.

We offer you to watch a video that tells how to make brakes on a trailer for a walk-behind tractor with your own hands:

Other details

In addition to the listed elements, it is possible to install additional parts that will expand the functionality of the trailer for the walk-behind tractor. When making a trailing device with your own hands, you can provide for the installation:

- folding bench. It is attached to the front side of the body using the side parts as support;

- spare wheel, which may be required when performing work outside the home. Most often, for its placement, a side board or the lower part of the pallet is chosen. To exclude its displacement, special fasteners are used;

- small boxes or special bagslocated near the driver's seat. They are used to store small tools that may be required when performing repair work.

PHOTO: a.d-cd.net

PHOTO: a.d-cd.netSelf-production of a hitch for a walk-behind tractor

A special hitch is used to connect the trailer to the walk-behind tractor. Its dimensions and design may differ depending on the model of the walk-behind tractor. In general, such a system should ensure the stability of the structure and facilitate the controllability of the walk-behind tractor.

PHOTO: stroy-podskazka.ru

PHOTO: stroy-podskazka.ruDrawings of a hitch for a walk-behind tractor

To make a hitch for a walk-behind tractor with your own hands, you need to develop a detailed drawing. It will contain all the necessary information about the main elements and their sizes. When developing a design, the features of the walk-behind tractor are taken into account. We offer you to get acquainted with the drawings of possible options:

PHOTO: referatdb.ru

PHOTO: referatdb.ru PHOTO: referatdb.ru

PHOTO: referatdb.ru PHOTO: f.6324780.xyz

PHOTO: f.6324780.xyz

How to make a hitch for a walk-behind tractor trailer: an algorithm of actions and video instructions

Drawbar - a system of welded pipes connected to the side member of the trailer. At the junction, a hitch for the walk-behind tractor is mounted. Its installation should be relatively simple. At the same time, the connection should be strong, reliable, making it possible to ensure easy rotation of the trolley with the walk-behind tractor.

Having studied the photos, videos, having developed drawings with dimensions for making a trailer with your own hands, you can start assembling the structure. The work is carried out in the following sequence:

- at the junction of the drawbar pipes, we weld on a piece of pipe with a diameter of 40 mm and a length of 10 cm;

- we press two bearings into the pipe;

- from the side of the trailer, install a washer on the pipe. It will be used to accommodate the threaded axle from the hitch;

- we form a coupling from a square pipe. For this, a through hole is drilled, the diameter of which is equal to the transverse dimensions of the fixing pin;

- we reinforce the square tube with a sheet of metal. The edges of the pipes are bent.

We offer you to watch the video, which tells how to make a trailer hitch for the Neva walk-behind tractor with your own hands:

The nuances of manufacturing other types of trailers for agricultural machinery

Trailers can also be attached to other types of agricultural machinery. When making such a design, a number of nuances should be taken into account. Attention is paid not only to the material, but also to the size of the structural elements.

DIY cultivator trailer: manufacturing nuances

Having made a trailer for a cultivator with your own hands, you can greatly facilitate the control of such a device. As a rule, such mechanisms have less power than walk-behind tractors. This affects the dimensions of the finished structure. We suggest watching the following videos to understand the nuances of manufacturing:

How to make a two-axle trailer for a walk-behind tractor: video instruction

If you plan to transport a large amount of cargo at a time, you should refuse to use a uniaxial model. She will not be able to withstand the load. In addition, it does not always have sufficient stability when moving over rough terrain. This could cause the structure to topple over. Biaxial devices have a shifted center of gravity.

Attention! Some owners use a ready-made car bridge to make a two-axle model. The design will allow you to transport a large volume of cargo, but it will turn out to be cumbersome.

We offer you to watch the video in order to better understand how to make a trailer with two axles to the walk-behind tractor with your own hands.

Tipper trailer for a walk-behind tractor: design features

A dump trailer for a walk-behind tractor makes it easier to unload the brought cargo. This design has an offset center of gravity to facilitate body tipping.

The ability to tilt the body is ensured by a special body structure. We offer you to watch the video to get acquainted with the nuances of manufacturing dump trailers:

Share in the comments whether you had to make a trailer for a walk-behind tractor with your own hands, and which design you preferred.