So that when performing construction and finishing works there were no difficulties, it is necessary to purchase the required volume of the working mixture in advance. For this, the consumption of cement is determined per one cube of solution for screeds, masonry, plasters and foundation, and then the required amount is calculated. There are a number of features that must be taken into account when calculating. This will avoid mistakes and help optimize costs.

Read in the article

- 1 Cement consumption rates for concrete and working mixtures according to SNiPs

- 2 What determines the consumption of cement for the preparation of 1 m3 of solution

- 2.1 Purpose of the prepared solution

- 2.2 Cement grade

- 2.3 Filler characteristics

- 2.4 Other factors

- 3 Cement consumption per one cube of mortar for screed, masonry, plaster and foundation: calculation procedure

- 3.1 Floor screed

- 3.2 Masonry mortar

- 3.3 Plaster mortar

- 3.4 Foundation grout

- 4 How many bags of cement will be needed to prepare the mixture

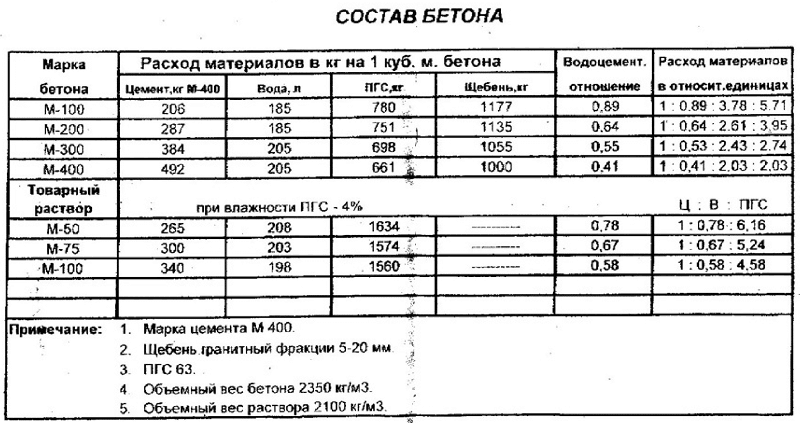

Cement consumption rates for concrete and working mixtures according to SNiPs

Consumption rates are regulated by the requirements of the relevant SNiPs. The document contains the minimum amount of a binder that must be introduced into the solution to ensure a sufficient level of strength and durability of the structure being manufactured.

Consumption rates differ significantly depending on what task the ready-made working mixture must solve. It can be used:

- when pouring the foundation;

- laying of blocks;

- pouring the screed;

- performing plastering work.

Regulatory documents reflect other requirements for the preparation of a working mixture. Failure to comply with the established rules may result in the imposition of an administrative penalty. A complete list of consumption rates can be found in the relevant SNiPs.

What determines the consumption of cement for the preparation of 1 m3 solution

The binder consumption is influenced by the purpose of the working mixture being prepared, the used brand, fillers and a number of additional factors.

Purpose of the prepared solution

The consumption of the working mixture can differ significantly depending on its purpose:

- screed - 575 kg / m3 when using M400 and 450kg / m3 when using the M500;

- foundation - 320, 300, 200, 170 kg / m3 when choosing brands M100, M150, M200, M250, M300, respectively;

- plaster - an average of 1.5 kg / m3 and does not depend on the brand used;

- walls - 230, 185, 300, 400 kg / m3 when using M150, M200, M300, M400.

Cement grade

The consumption rate largely depends on the brand used in the preparation of the working mixture. In accordance with regulatory documents, for the preparation of M100 concrete, 170 kg of a binder will be required. For M150, M 200, M 250, M300, M400, M500, you will need 200, 240, 300, 350, 400, 450 kg, respectively.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"After long-term storage, the cement loses its properties and its grade decreases."

Filler characteristics

To obtain certain properties, a certain amount of fillers is introduced into the composition of the prepared solution. These include:

- modifiers that increase the strength and frost resistance of the formed structure;

- plasticizers that increase the mobility and water resistance of the mixture;

- mobility regulators that extend the setting time - thanks to their introduction, it is possible to preserve the mobility of the mixture when it is delivered to the place of work;

- anti-frost additives, with the introduction of which it becomes possible to perform work at negative temperatures;

- setting accelerators - thanks to them, it is possible to achieve maximum setting already in the first day.

Other factors

In addition to the above, there are a number of additional factors that must be taken into account when performing calculations:

- filler volume - the more sand and gravel is added to the solution, the more binder will be required. It provides high-quality bonding of the particles of the prepared mixture;

- ratio of components - it may be different;

- cement density - the average value is 1300 kg / cu.

Cement consumption per one cube of mortar for screed, masonry, plaster and foundation: calculation procedure

The calculation can be different. We offer you to get acquainted with the methods that will help you calculate the cement consumption when performing various types of work.

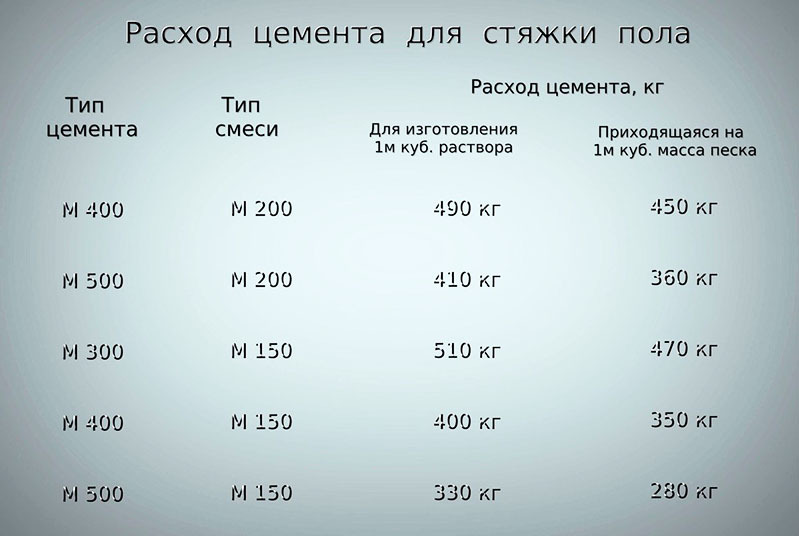

Floor screed

To prepare a concrete solution for floor screed, three parts of a sand mixture are added to one part of the cement. When calculating the upcoming consumption, proceed in the following sequence:

- the thickness of the formed layer is determined;

- the screed area is calculated - if the floor surface has an irregular shape, for ease of calculation it is divided into separate simple shapes;

- the required volume in cubic meters is determined;

- the brand that will be used in the preparation of the concrete solution is selected. Based on this, it is determined how many kilograms will be in 1 cube.

Masonry mortar

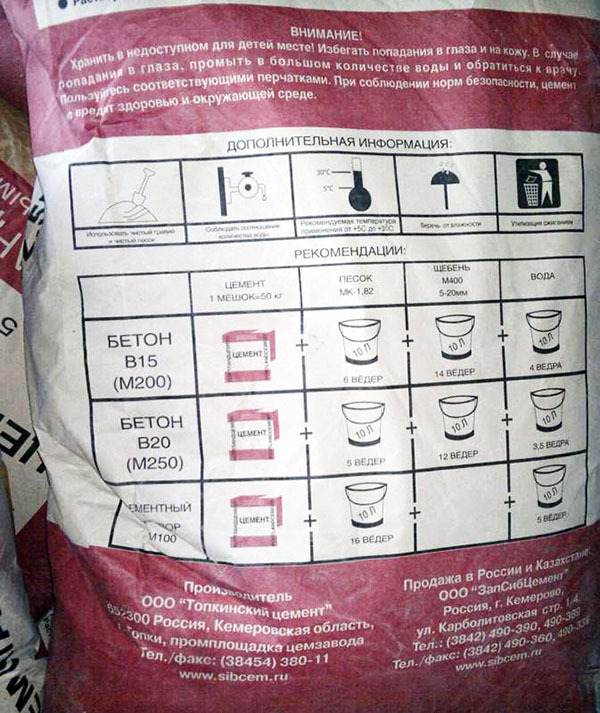

When calculating the required volume, it is taken into account that at least 75 liters of M100 mortar will be required for laying a square with a brick thickness. For its preparation, cement M400 and sand are mixed in a ratio of 1 to 4. As a result, to obtain a cube of concrete solution, it is necessary to mix 200 kg of cement and 800 kg of sand. To calculate the total, the total area of the brick walls is calculated.

Plaster mortar

When preparing the solution, the components are mixed. You need: three parts of sand and a part of cement, to which a sufficient amount of water is added. To form one square of a layer less than 12 mm thick, 1.6 kg of M400 binder or 1.4 kg of M500 will be required. When calculating the total amount, the required volume is determined based on the thickness of the layer being formed. The total area is found and multiplied by the number of kilograms in one square.

Foundation grout

When calculating the required amount, a special calculator is most often used to determine the volume and ratio of the components. If it is absent, you can make a manual calculation. For this:

- Determined with the brand of cement mortar that will be used when performing work. Most often, the choice is made in favor of the M100 - M300. The higher the load, the more solid the base must be. For private houses, M150 is chosen, for multi-storey houses - M200. For construction from wood, M50 is enough.

- Choose a brand. This will allow you to understand how much of a binder will be present in the finished solution.

- Calculate the total volume of the base.

- Determine the required amount of cement based on its brand.

Attention! When calculating, it can be roughly assumed that when using M300 / M400 cement, 3 parts of sand will fall on one part of the binder. If you plan to use the M500, the ratio changes by 1 to 5.

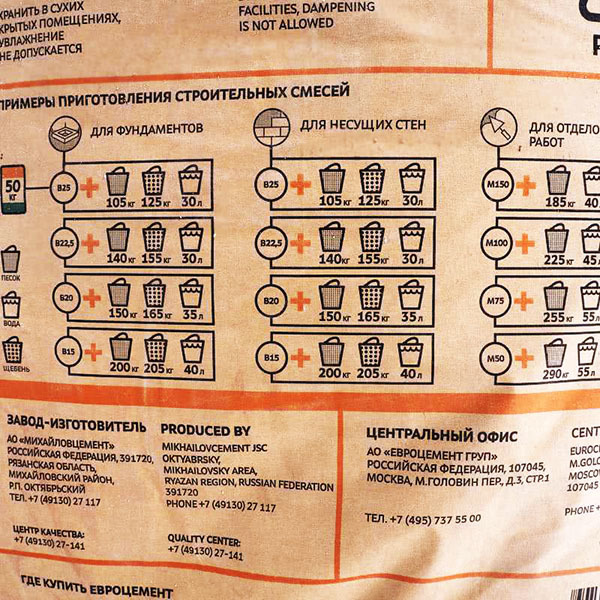

How many bags of cement will be needed to prepare the mixture

The calculation of the required number of bags is carried out using proportions. So, if a quarter of the binder is required to prepare one cube of solution, then 250 liters of cement must be purchased. The bulk density is 1.4 kg / l. To calculate the required amount of material, the specified value must be multiplied by the required volume. After that, it remains only to divide the resulting product by the number of kilograms of cement contained in one bag in order to determine how many bags to purchase.

Share in the comments if you had to calculate the required amount of cement or if you prefer to seek professional help.