Until relatively recently, the only possible way to level the floors was a conventional cement screed, exposed along the lighthouses. Today, manufacturers offer many different brands of self-leveling floor, which practically does not need to be leveled. The only problem is the high cost of foreign-made materials. However, the Russian manufacturer also does not stand still, offering cheaper, but no less high-quality mixtures. In today's article we will talk about self-leveling floors "Prospectors", which are gaining more and more popularity in our country.

Read in the article

- 1 Briefly about the producer of self-leveling floor "Miners"

- 2 Where self-leveling floors "Prospectors" are used

- 3 Some performance characteristics of self-leveling floors "Prospectors", depending on the type

- 3.1 Self-leveling floors "Prospectors Rapid-hardening": features of the mixture

- 3.2 Prospectors Thin and its differences

- 3.3 Prospectors Tolstoy - another construction composition

- 3.4 Prospectors Practical with less durability

- 3.5 The most interesting composition "Prospectors High Strength Self-Leveling"

- 4 Advantages of the "Prospectors" compositions and their disadvantages

- 5 Calculation of the consumption of the building mixture when pouring the floor

- 6 Installation of self-leveling floor "Prospectors": work progress step by step

- 6.1 Preparing the floor for pouring

- 6.2 Fill tool

- 6.3 Mixing the self-leveling floor

- 7 Possible defects of the self-leveling floor and their causes

- 7.1 Problem number 1: peeling of the self-leveling floor from the base

- 7.2 Problem # 2: surface cracking

- 7.3 Problem # 3: lack of smoothness - rough surface

- 8 Let's sum up

Briefly about the producer of self-leveling floor "Miners"

The firm "Prospectors" was organized by six fellow students of the Moscow Aviation Institute, who in the dashing nineties decided to change the "sky" for a more practical "land". At first, the company was exclusively engaged in the manufacture of plaster putty. The excitement around various variations of European-quality renovation in those years helped the guys quickly unwind, gaining momentum. Today the geography of plants producing dry construction mixtures is quite extensive. Enterprises in Moscow and Stary Oskol operate under this brand. The firm did not bypass the Khabarovsk Territory, the Ulyanovsk Region, the Republic of Buryatia.

In addition to building mixtures, which are produced at factories of more than 2500 tons per day, the company also produces equipment for their use. But today we will talk about such a mixture of them as a self-leveling floor.

Where self-leveling floors "Prospectors" are used

The scopes of self-leveling floors are limited to horizontal surfaces. This can be a rough screed or leveling layer in residential and industrial premises, as well as a topcoat (in rare cases). The use of such mixtures for leveling walls or ceilings is impossible.

Some performance characteristics of self-leveling floors "Prospectors", depending on the type

There are several types of similar building mixtures, including:

- fast hardening;

- thin;

- thick;

- practical;

- self-leveling high strength.

Each of the types has its own characteristics and is used in a specific specific case.

Self-leveling floors "Prospectors Rapid-hardening": features of the mixture

Comments are superfluous, the name speaks for itself. But there are a few things worth mentioning. The composition is intended for screed (both rough and final), and its drying time is 4 hours. The layer thickness is strictly from 5 to 9 cm. This mixture requires additional leveling when pouring, using a special needle roller. Although it is recommended to perform such actions, working with other compounds. The compressive strength is 15 MPa.

Prospectors Thin and its differences

This composition is very fluid. Pouring is done over the rough screed, the layer should not exceed 2-3 cm. Actually, this is the maximum difference that such a self-leveling floor can level. Compressive strength corresponds to the previous version. Drying time 6 hours.

Prospectors Tolstoy - another construction composition

It is used for rough screed, leveling differences up to 100 mm. Drying time is longer than in previous versions. The screed can only be used after 48 hours.

Prospectors Practical with less durability

This composition is more resistant to cracks, but its compressive strength is slightly lower - 12 MPa. The drying time of the mixture is 4-6 hours, but the viability of the finished solution is only 40 minutes, so after mixing it, you should hurry up.

The most interesting composition "Prospectors High Strength Self-Leveling"

Weather- and frost-resistant, very durable after drying. When pouring, you just need to push it in the corners into which the composition could not flow. After 24 hours, the master gets a perfectly leveled floor, which can be coated with, for example, epoxy without any treatment. Laying tiles on such a floor turns into a holiday at all. When using a more liquid tile adhesive than usual, the laying time of the coating is several times reduced, and the need for using a building level disappears.

All compositions can be dyed in different colors by mixing ("Prospectors" color is sold separately). The forms of production of such building mixtures are kraft bags of 20 and 25 kg.

Advantages of the "Prospectors" compositions and their disadvantages

The advantages of using the "Prospector" self-leveling floor can be listed for a very long time, and therefore it is worth noting only the main ones, among which:

- convenience of working with mixtures, no need to display beacons and, as a result, reduction in repair time;

- lack of seams on the finished surface;

- resistance to mechanical damage and fire safety;

- production capability accurate calculation of the mixture consumption;

- durability, environmental friendliness of the composition.

But in the "barrel of honey" you need to add a "fly in the ointment", having considered the disadvantages:

- the cost, in comparison with a cement screed, is quite high;

- plus strength turns into minus if dismantling is necessary;

- violation of the manufacturer's recommendations for mixing leads to a loss of basic strength properties.

Calculation of the consumption of the building mixture when pouring the floor

On each package of the self-leveling floor "Prospectors", the average consumption of the composition per 1 m² with a layer thickness of 1 cm is indicated. This indicator is different for each type. It composes:

- Prospectors Fast-hardening - up to 17 kg / m²;

- Thin - the same 17 kg / cm²;

- Thick - up to 18 kg / cm²;

- Practical - 14-15 kg / cm².

Installation of self-leveling floor "Prospectors": work progress step by step

To begin with, as before any other work, you need to prepare the entire tool that will be used, as well as the required amount of dry mixture and water. But the composition cannot be poured onto an unprepared surface, so it is worth considering what needs to be done at this stage.

Preparing the floor for pouring

The preparation of the floor for pouring the mixture "Prospectors" is carried out in several stages.

- The old coating is removed.

- Garbage is removed, the surface is dust-free.

- Concrete build-ups get lost, cracks and chips are smeared over. Holes in ceilings are best filled with polyurethane foam.

- The entire floor surface is carefully primed.

- A damper tape is glued along the edge, and the height of the future self-leveling floor can be marked on it.

Fill tool

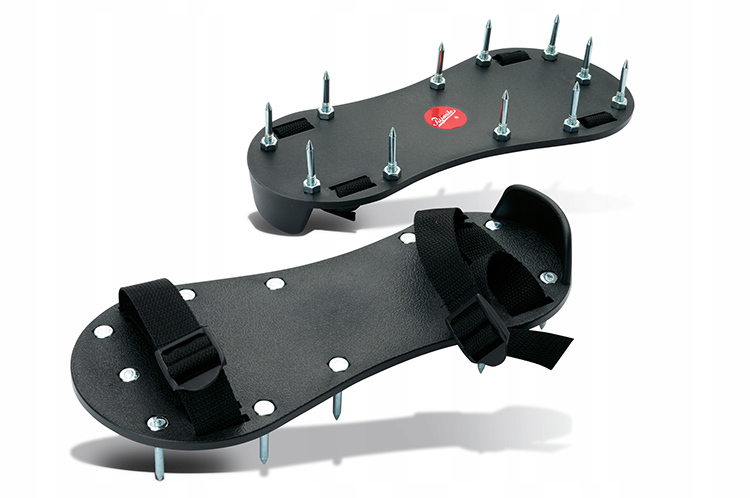

The set of tools, regardless of the type of mixture, is always standard. This is a drill or mixer with an attachment for mixing the mixture, a squeegee, a needle roller. In order for the master to move around the uncured solution without harming the surface, needle soles are used.

Mixing the self-leveling floor

When mixing a self-leveling floor, the dry mixture is poured into the water, and not vice versa - this is very important. For 25 kg, no more than 6 liters of water is added, then it is necessary to look at the consistency. It is more convenient if the work is performed by 2 people - one kneads, the second pours and levels.

Pouring is done from the far corner of the room to the exit. After spilling, the mixture is accelerated with a squeegee. After the room is completely filled, the surface must be rolled with a needle roller, which will help to expel the air remaining in the mixture.

Possible defects of the self-leveling floor and their causes

If the manufacturer's recommendations are not followed, many problems can arise after the self-leveling floor has dried. It makes sense to consider the main defects that are found in houses and apartments, as well as the reasons for their occurrence.

Problem number 1: peeling of the self-leveling floor from the base

The reason for such a nuisance may be insufficiently thorough dedusting of the surface before pouring. Also, the fault may be a poor-quality mixture, which was used for priming. The next possible reason is poor mixing of the composition when it is added to the water. Finally, insufficient needle rolling. The air remaining inside changes its properties under the influence of temperature differences, which leads to delamination.

Problem # 2: surface cracking

It is also quite common. The main reason is non-compliance with the pouring technology in terms of the layer thickness. A layer that is too thick cannot dry out as provided by the manufacturer. Also, improper mixing may be the culprit, namely, adding more water than the instructions require.

A wet or moving screed also causes the self-leveling floor to crack. And, of course, the use of an expired composition or its incorrect storage.

Problem # 3: lack of smoothness - rough surface

Here all the blame again falls on the shoulders of the master. Insufficient dedusting with a thin layer leads to just such consequences. Dry dust floats to the top and forms a sandpaper-like surface. The dustiness of the air in the room during the drying of the self-leveling floor will also lead to the same result.

There are other problems that arise after the self-leveling floor dries. But they all appear only due to non-compliance with the manufacturer's recommendations.

Let's sum up

Such mixtures greatly facilitate the process of leveling surfaces. As for the self-leveling floor "Prospectors", this composition, being on the same level with foreign counterparts in quality, significantly surpassed them in availability. Its cost is higher than that of cement or PCS, however, it cannot be called transcendental. Self-leveling floor "Prospectors" is available at a price to any consumer. And if the master strictly adheres to the manufacturer's recommendations related to storage, mixing and pouring the floor with a similar composition, he can be completely confident in the result. The floors are flat, smooth and durable. A bonus to this is low labor costs and the absence of the need to display beacons.

We hope that the information presented today was interesting and useful to our reader. The huge amount of information collected about the self-leveling floors "Prospectors" cannot be accommodated in one article, so a lot has been left behind the scenes. If something seemed incomprehensible to you, state the essence in the comments below. HouseChief editors will definitely clarify all the unclear points.

Did you like today's article? Then don't forget to rate it. Finally, we offer for viewing a short but very informative video on today's topic.