Plasterboard structuresdue to their versatility, they are widely used in renovation work in residential, commercial, technical and industrial premises. Their strength and appearance not least depends on the type of fastening materials used. This article will focus on how to choose self-tapping screws for drywall, the types of hardware, their main characteristics and areas of application will be considered.

Read in the article

- 1 Classification of self-tapping screws for drywall

- 1.1 By material of manufacture

- 1.2 By type of thread (purpose)

- 1.3 By tip type

- 1.4 By size

- 1.5 By protective (anti-corrosion) coating

- 2 How to choose the right type of self-tapping screw for drywall

- 2.1 Depending on the base material

- 2.2 For attaching objects to the wall

- 3 Regulatory requirements for self-tapping screws for gypsum board (500)

- 4 Leading manufacturers

- 5 Practical advice on using self-tapping screws for gypsum board

- 6 Summing up

Classification of self-tapping screws for drywall

The building materials market offers a wide selection of fasteners that can be used when installing plasterboard structures. Most often, the classification of self-tapping screws for gypsum board is carried out according to the following parameters:

- material of manufacture;

- purpose (type of thread);

- tip type;

- sizes;

- type of anti-corrosion coating.

Let's consider the listed parameters in more detail.

By material of manufacture

The performance characteristics of drywall screws directly depend on the material of manufacture and its heat treatment. Most often, the following materials and technologies are used in production:

- carbon steel (GOST 1050) with a protective zinc and zinc-chromating coating applied by galvanizing;

- alloy steel (GOST 4543) with a phosphate coating or without an adhesive anticorrosive layer (protection against moisture is realized by simple oiling with mineral oils);

- stainless austenitic steel grade A2 or A4 (AISI 304) without additional protective coatings;

- brass - self-tapping screws are produced according to technical conditions (TU), the material is characterized by high resistance to corrosion, but low strength characteristics. It is approved for use in self-supporting structures that are not subjected to significant mechanical stress.

Self-tapping screws with self-tapping screws are made of steel 10kp, 10, 10ps (GOST 11650 and GOST 11652). They undergo additional heat treatment - hardening.

By type of thread (purpose)

The main difference between drywall screws is made by the type of thread on which the area of use depends:

- for attaching drywall to a metal profile, a fine thread pitch, a sharp hardened or drill tip is used;

- for fixing the gypsum board on a wooden frame - the thread pitch is wide. This gives an additional area of contact between the fastener and the wood, which contributes to the strength of the hold.

Important! If, for reliable fastening of drywall on a metal profile, the screws are long enough for 5-7 mm more than the thickness slabs, then for a wooden frame there is a rule - the softer the wood, the longer the screw is needed use. For example, for pine, the length of the hardware in the wood must be at least 15 mm.

By tip type

For fastening the gypsum board on a wooden frame or on a metal profile, the thickness of which does not exceed 1.2 mm, screws with a sharp tip are used. If the metal thickness is 1.2-2.0 mm, then screws with drill tips are used. With the total thickness of the metal profile exceeding 2 mm, the hole is pre-drilled.

By size

Self-tapping screws for drywall are produced in the following nomenclature of standard sizes: length 16-152 mm, diameter 3.5-4.8 mm. Most often they use the 3 most common sizes, which, in principle, will be enough to create a drywall structure of any complexity:

- TN 25 (3.5 25 mm). They are used when fixing sheets to a metal profile. Equipped with a more reliable anti-corrosion coating. The shape of the screw head allows it to be screwed into the base flush.

- TN 45 (3.5 45 mm). It is used in the installation of multilayer structures made of gypsum plasterboard. It can also be used to fix suspensions.

- TECH 9.5 (3.5 9.5). They are used to connect frame elements made of plasterboard profiles. They often have a self-tapping (drill) tip.

By protective (anti-corrosion) coating

Self-tapping screws for drywall are exposed to high humidity both during puttying and during further use. Therefore, the utmost attention is paid to the issues of anti-corrosion protection. During production, three methods of protection are used:

- Oxidation - the protective film is formed under the influence of high temperature in combination with acid vapors. The products are black with a smooth texture. The film is characterized by medium resistance to mechanical stress. Recommended for use in rooms with normal humidity.

- Phosphating - the coating is formed as a result of a chemical reaction between phosphate and iron salts. The resulting anticorrosive layer is characterized by high adhesion both to the base and to the paintwork. The appearance of the coating is black, slightly rough. Recommended for use in rooms with high humidity for fixing elements that will be painted later.

- Galvanized - applied by sendzimir or electric, forms a reliable protective coating with a thickness of 50-150 microns. It is characterized by high resistance to moisture and various chemically active components, which is especially important when finishing with decorative plasters. The appearance of the coating is white or yellow. It is used indoors with high humidity and outside buildings.

How to choose the right type of self-tapping screw for drywall

When choosing fasteners for plasterboard structures, it is recommended to pay attention to the main indicators.

Dimensions (edit). Depend on the thickness of the gypsum plasterboard structure (the number of plasterboard layers) and the base material. For example, when mounting in one sheet on a metal profile frame, it is allowed to use self-tapping screws 25 mm long. And when mounting in 2 sheets or on a base of wooden beams, the recommended screw length is 35 mm. The nomenclature of sizes of self-tapping screws used for fastening elements of plasterboard structures is:

- length 9.5-45 mm;

- thickness 2.5-4.8 mm.

Thread pitch. Depends entirely on the base material. For wooden structures, a screw with a rare thread is used, and for a metal profile - with a frequent one.

Form Factor. This indicator includes the shape of the tip, screw head and slot type. For the installation of the gypsum board, screws are used that have the shape of a countersunk or semi-countersunk head. For the installation of the supporting structures of their profiles, it is better to use self-tapping screws with a semicircular head or press washer.

Most often there are various types of cross-slotted drywall screws:

- Philips -type "H";

- Pozidriv - type "Z";

- Torx - Star type.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

"As practice shows, Pozidriv splines are best for efficient use of a screwdriver, and Torx for manual tightening with maximum force."

Manufacturing material and anti-corrosion coating. It is best to use hardened, phosphated coated screws. They have an optimal ratio of cost and performance and are suitable for almost all types of drywall work.

The video shows the main criteria for choosing self-tapping screws for drywall:

Depending on the base material

Plasterboard installation technology provides for its installation directly on a brick or concrete wall. In this case, fastening is carried out using glue mixtures and dowel-nails. Dowel-nails are a set consisting of an impact screw and a plastic dowel of the appropriate size. The impact screw also has a screw thread just like a regular screw. However, the flanges of the cut are in the form of a cone tapering towards the tip. Thus, they gain additional strength and facilitate the process of driving the screw into the dowel.

The plastic dowel has a spacer part and a mushroom-shaped or hidden collar. Regardless of the shape of the collar, the dowel is completely hammered into the drywall sheet, after which the screw is screwed in flush with the surface of the gypsum board.

For attaching objects to the wall

During the operation of a room lined with gypsum board, it is guaranteed that there will be a need to fix any object on the wall surface: a picture, a shelf, a sconce, a TV and etc. Hanging various objects on screws or nails is not possible, since the area of application of the bending force will be too small, and drywall will crumble. To solve this problem, special fasteners have been developed that increase the contact area:

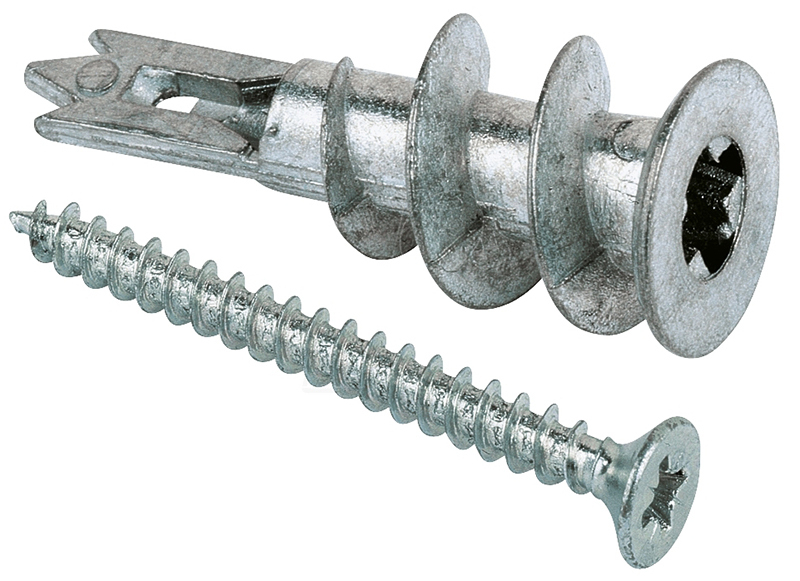

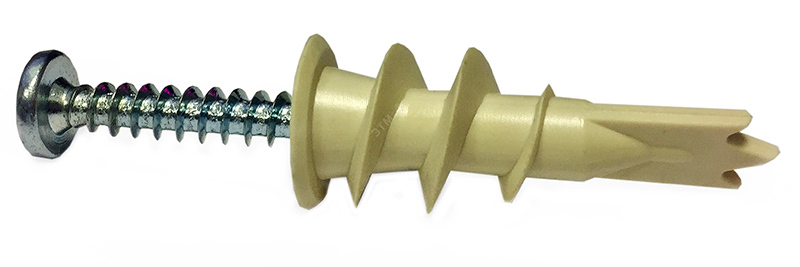

- special plastic or metal dowels-drills of large diameter. They are screwed into drywall without pre-drilling a hole. They give a minimal effect, it is allowed to use only for fastening light objects up to 5-7 kg;

- dowel "Butterfly" - consists of a plastic base, divided lengthwise into 2 parts. Hammered into a pre-drilled hole. Then the screw is screwed in, and the plastic component expands, adhering tightly to the inside of the drywall sheet. Withstands weight up to 15 kg per fastener;

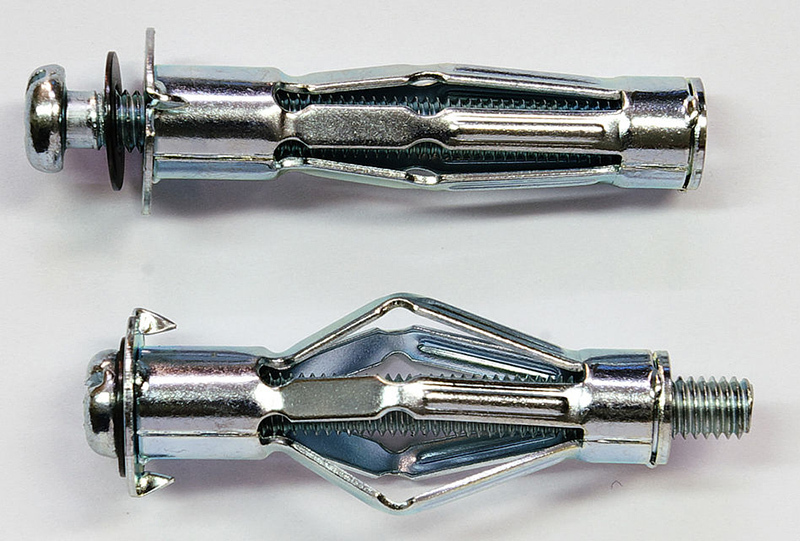

- dowel "Molly". The basic design and principle of operation is similar to the butterfly dowel. The fasteners are made of metal, and the movable part is divided into four segments. This gives a large seating area. The permissible weight, depending on the size, is 15-25 kg.

Metal and plastic dowel-drills:

The video shows the principle of operation of the Molly dowel:

Regulatory requirements for self-tapping screws for gypsum board (500)

Technical and operational characteristics of self-tapping screws for drywall must comply with the following standards:

- main standard sizes GOST 10619-80 and GOST 11651-80 for products with countersunk head, GOST 10620-80 and GOST 11652-80 for screws with half-countersunk heads;

- mechanical properties: thread pitch, hardness, thread-forming ability, torsion resistance, as well as test methods - GOST R ISO 2702-2009;

- the shape and depth of the slot - GOST R ISO 7050-2012 for a countersunk head, GOST R ISO 1483-2013 for a half-countersunk head.

Leading manufacturers

The domestic market for fasteners is filled with cheap but low-quality Chinese-made hardware. Their only advantage is the extremely low price due to the use of low-quality materials. The price for screws of European production (Poland, Czech Republic, Germany) is unreasonably high. We offer a brief overview of the leading domestic companies engaged in the production of fasteners:

- Normand fasteners - production facilities are located in Podolsk, Moscow region. Specializes in the production of fasteners, including for roofing and drywall;

- Kemcrepe - the city of Kemerovo, produces self-tapping screws with an oxidized protective coating. Raw materials for the manufacture are also of domestic production - from the city of Severstal;

- PROF-MET - the city of Dimitrovgrad, Ulyanovsk region. Produces self-tapping screws with coarse threads with an oxidized anti-corrosion coating;

- MMK-METIZ - the city of Magnitogorsk, Chelyabinsk region. Produces a wide range of hardware from high-quality domestic steel;

- Severstal Metiz - the city of Volgograd. Produces self-tapping screws in a wide range of standard sizes.

Practical advice on using self-tapping screws for gypsum board

To increase the strength characteristics of the drywall structure, it is important not only to choose the appropriate type of self-tapping screws from high-quality materials, but also to carry out the installation correctly:

- fasteners are screwed in at the same distance from each other. This will allow to more evenly distribute the load on the supporting elements;

- the use of a screwdriver not only facilitates the work, but also maintains the integrity of the gypsum board near the fastener. This further strengthens the structure;

- It is recommended to screw in the first half of the screw at high speed, and after the self-tapping screw goes deep into the supporting base, reduce the speed to the minimum;

- the depth of immersion of the head of the self-tapping screw into the sheet should not exceed 1-1.5 mm.

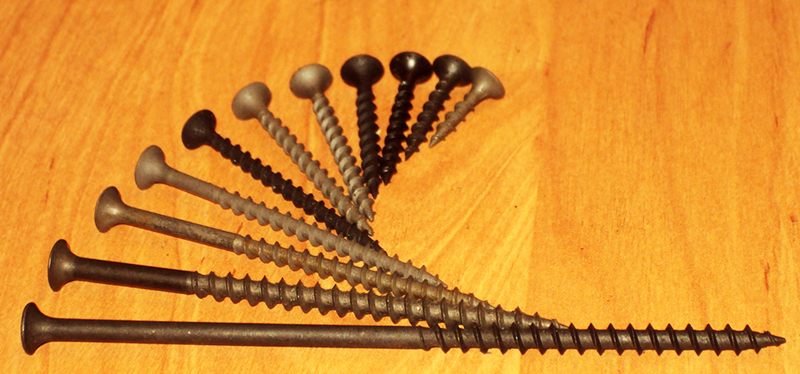

The photo below shows the main types of self-tapping screws for gypsum board.

1 out of 8

PHOTO: stroilko.info

PHOTO: detali-mebeli.ru

PHOTO: prorab.ru

PHOTO: svarog-tk.ru

PHOTO: 999111.ru

PHOTO: res.cloudinary.com

PHOTO: stroimdom44.ru

PHOTO: mr-build.ru

We bring to your attention a video in which the features of fastening drywall with your own hands are discussed in more detail:

Summing up

Choosing the right self-tapping screw for gypsum board is a responsible process. Poor-quality fasteners, errors in the selection of the required type will not only significantly complicate the work, but also reduce the strength of the entire plasterboard structure. We hope that the information above was useful to you. Recommend the article to your friends and take part in its discussion.