Various indicators are used to characterize the operational and physical and mechanical properties of materials. The modulus of elasticity of concrete, which characterizes the ability to elastically deform as a result of the action of external force and pressure, has become widespread. To understand the properties of the ready-made concrete solution, it is worth finding out what it is, what it depends on and how it is determined.

Read in the article

- 1 Concrete modulus of elasticity and units

- 2 Factors affecting the modulus of elasticity of concrete

- 2.1 Quality and volumetric content of aggregates

- 2.2 Concrete class

- 2.3 Air temperature and humidity

- 2.4 Exposure time and curing conditions of the mixture

- 2.5 Age of concrete and structural reinforcement

- 3 Modulus of elasticity of concrete (Eb): methods of determining the value

- 3.1 Mechanical test

- 3.1.1 Materials and tools

- 3.1.2 Sample testing scheme

- 3.2 Non-destructive ultrasonic method

- 3.1 Mechanical test

Concrete modulus of elasticity and units

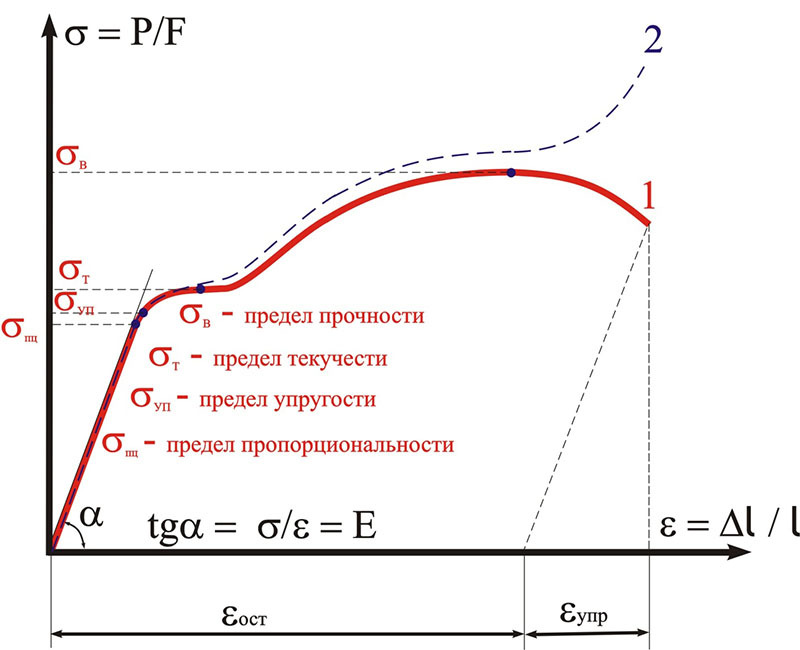

During operation, solids are loaded and begin to deform. At first, the flowing deformation changes are reversible, and their magnitude from the applied force is linear. As soon as the load is removed, the product completely restores its original shape. To describe the ongoing processes, Hooke's law is used, according to which, as a coefficient proportionality between absolute compression or elongation and applied force modulus is used elasticity.

The definition of this indicator is as follows: modulus of elasticity - the coefficient of proportionality between the normal stress and the corresponding relative longitudinal deformation. Measured in kgf / cm² (N / m², Pa). It is called Young's modulus.

As soon as the load exceeds a certain level, the phase of irreversible changes begins. Deformability becomes inelastic. The shear increases without further load application. In the creep zone, internal bonds begin to break down and the concrete structure loses strength.

Factors affecting the modulus of elasticity of concrete

The value of the modulus of elasticity can vary significantly. It is influenced by many factors. To get the desired result, it is worth getting to know them in advance.

Quality and volumetric content of aggregates

Concrete is a mixture of some cement and aggregates. The quality and concentration of the latter have a direct impact on the value of the elastic modulus. If the structure is inhomogeneous, the likelihood of a complex stress state increases significantly. The main load falls on the hard particles. Areas with voids and pores undergo transverse tension.

Attention! The introduction of coarse aggregate into the composition helps to increase the elastic properties of reinforced concrete.

Concrete class

The concrete class has a direct impact on the elasticity model. The higher the class, the greater the compressive strength and density the composition will have and the better it will resist the acting load. Highest value – near concrete B60 – numerically equal to 39.5 MPa × 10-3. The smallest value is at B10 and corresponds to 19 MPa × 10-3.

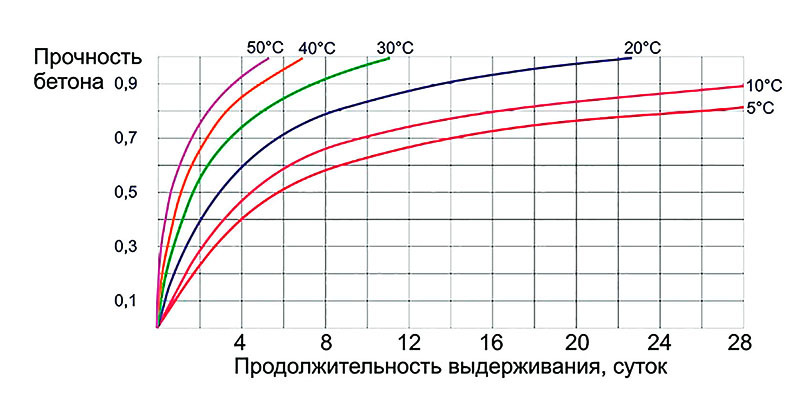

Air temperature and humidity

As the temperature rises, the deformation in concrete increases and the elastic properties decrease. This contributes to an increase in the internal energy of the mixture, as well as the linear expansion of the material, the trajectories of molecular motion, and an increase in plasticity.

Attention! Temperature fluctuations are only taken into account if their range exceeds 20 ° C.

Moisture affects the elasticity of the material. The creep coefficient is used in the calculations. The higher the percentage of water vapor, the lower the plastic deformation will be.

Exposure time and curing conditions of the mixture

The duration of the load on the concrete structure also affects the modulus of elasticity. If loading is carried out, instantly the deformation of the structure increases in proportion to the applied external forces. Prolonged voltage leads to a decrease in the magnitude of the module. The dependence is non-linear. Plastic and elastic deformation add up.

The conditions under which concrete gains its strength can vary. In natural conditions, the value is always higher. If the material is processed in an autoclave or steamed under atmospheric pressure, the value will decrease slightly. The reason for this is the formation of a large number of voids and pores due to uneven temperature expansion of the volume, a decrease in the quality of hydration of cement grains.

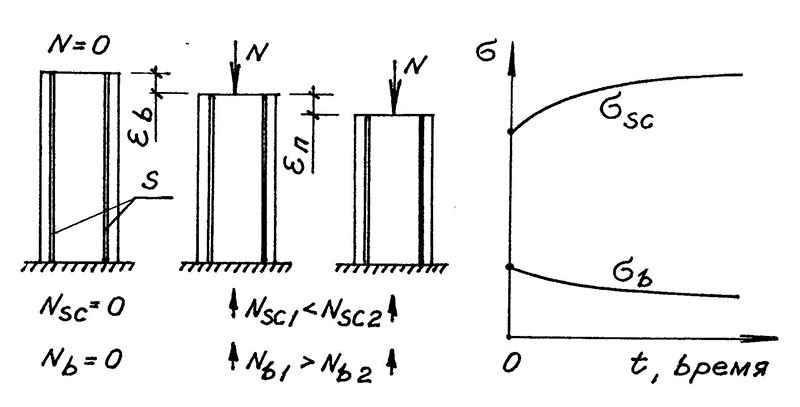

Age of concrete and structural reinforcement

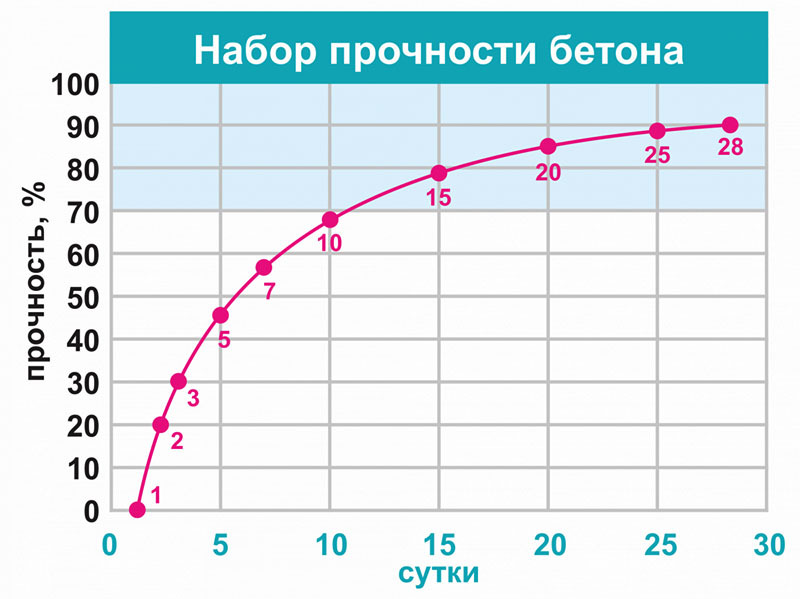

Freshly poured concrete takes four weeks to cure. After the specified period, the mixture will have elastic properties and sufficient plasticity. The maximum hardness will only be reached after 200-250 days. It is at this time that the modulus of elasticity reaches its maximum value corresponding to the brand strength.

In order for the mounted structure to last longer, it must be reinforced. As reinforcing elements, a mesh or a frame is taken, for the manufacture of which reinforcement belonging to the classes AI, AIII, A500C, At800, wood and composites was used. All these elements in the process of operation perceive tensile and compressive loads acting on the bud.

Thanks to the reinforcement, it is possible to increase the elasticity and strength characteristics of the structure. The likelihood of cracking of the deformation and shrinkage type is reduced.

Modulus of elasticity of concrete (Eb): methods of determining the value

The procedure for determining Eb may differ slightly. Each method has its own distinctive features. It is worth familiarizing yourself with the nuances of each method in order to avoid mistakes at the time of determining the value.

Mechanical test

During mechanical tests, the sample is destroyed. The research is carried out taking into account the requirements of GOST 24452, which establish the requirements for the samples used and the procedure for conducting research.

Materials and tools

For research, samples are used that have the shape of a circle or a square. The ratio of height and cross-section is taken equal to four. Samples are drilled out, drilled out or cut from the finished product. They are kept under a damp cloth prior to testing.

To obtain the desired value, the samples are placed on a press equipped with special bases that allow you to measure the deformation. The instruments are positioned at different angles to the sample edge. Steel frames are used to fix the indicators. In some cases, the indicators are glued to the support inserts.

Attention! If the structure operates in high humidity conditions, special training is required in accordance with GOST 24452-80.

Sample testing scheme

The tests are carried out in the following sequence:

- Samples are prepared and placed under a press with indicators, achieving alignment of the sample axes and the center of the plate. Destructive load is assigned in t / m2. The value depends on the grade strength of the concrete.

- A stepwise increase in the load is performed with a step of 10% of the destructive one and with an interval of 4-5 minutes.

- Bring the value to 40-45% of the maximum. In the absence of additional requirements, the devices are removed, and further loading is performed at a constant speed.

- The results for each sample are processed when the load is 30% of the breaking load. The data is displayed in the test log.

According to the research carried out, the initial modulus of elasticity Eb is determined. The guideline values for each class are contained in the building code tables and product labeling. For B15, B20, B25, B30, obtained under natural hardening conditions, the coefficient is 23, 27, 30, 32.5 MPa × 10-3 respectively, under heat treatment conditions - 25, 24.5, 27, 29.

Non-destructive ultrasonic method

The mechanical method involves removing a sample from an already finished structure. This is not always convenient and involves a number of difficulties. The ultrasonic method makes it possible to do without local destruction. In conditions of high humidity, the error is 15 -75% due to the higher propagation speed of ultrasonic waves in the aquatic environment. There is a method that allows you to find the value at different moisture content of the material. The tests are carried out on samples with different water saturation.

To find the standard and calculated values, correction factors are used, taking into account the corresponding values. The technique is given in SP 63.13330.2012.

Share in the comments which method you trust the most for determining the modulus of elasticity of concrete and which one you had to use.