When arranging premises, the operation of which is associated with high humidity (bathroom, bath, pool, etc.), it is necessary to ensure reliable waterproofing. It will protect building structures from the destructive effects of moisture, as well as from the claims of neighbors below, in the event of pipe leaks in the apartment. The new word in construction is the RPG panels, which we will take a look at in today's HouseChief review.

Read in the article

- 1 What are RPG panels

- 2 Construction of waterproofing panels

- 3 Where RPG panels are used

- 4 Advantages and disadvantages of RPG panels

- 5 Assortment of panels and their application depending on the thickness

- 5.1 RPG 10 mm

- 5.2 Using RPG panels 20mm

- 5.3 Slabs with a waterproofing layer of 30-40 mm

- 5.4 Expansion with RPG panels 50-60mm

- 5.5 Waterproofing panels RPG 80-100 mm

- 6 Installation features

- 7 A few words in conclusion

What are RPG panels

RPG panels are hydro-, sound- and heat-insulating material based on extruded polystyrene foam. It has long been successfully used in construction as a solid insulation. Taking polystyrene foam as a basis, building materials manufacturers reinforced it with a reinforcing fiberglass mesh and two special layers that improve technical characteristics.

The result is a multifunctional material that can be simultaneously used for:

- leveling surfaces;

- soundproofing;

- wall insulation and floors;

- waterproofing works;

- bases for finishing.

Construction of waterproofing panels

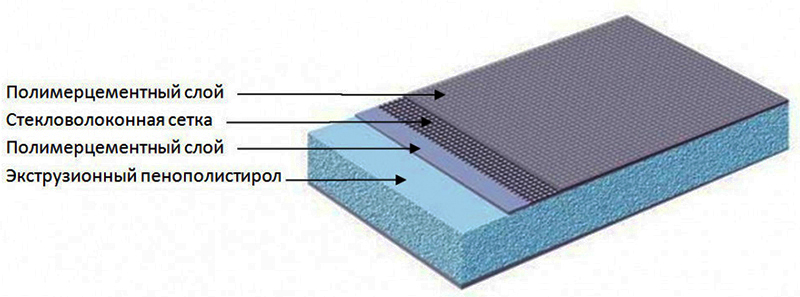

Such high technical characteristics of RPG panels are achieved due to the special design of the material, in particular:

- Extruded XPS foam core.

- Reinforcing fiberglass mesh.

- Upper and lower polymer-cement layer.

It is extruded XPS, not EPS foam, that is used as the main component for making RPG boards, since it does not rot, does not absorb moisture and does not react with construction solutions. In addition, this material does not have linear expansion, which means that the finishing layer does not deform during temperature fluctuations.

Fiberglass mesh, used as a one- or two-sided reinforcement layer, enhances the strength characteristics of the panel. This allows you to create structures from them that do not require a frame system.

Polymer cement layers are a binder component.

Where RPG panels are used

Due to their qualities, RPG waterproofing boards have a wide range of applications. In particular, they are used:

- to create a basic base for the arrangement of floors;

- as an interlayer between different materials;

- to create structures that do not require a frame (showers, partitions, podiums, etc.);

- for leveling walls with simultaneous insulation and sound insulation;

- for insulation of loggias, balconies, foundations and walls of buildings of all types;

- for waterproofing in rooms with high humidity;

- for facing internal and external slopes, as well as arched openings;

- for roofing works;

- when arranging adjoining blind areas;

- in landscape construction.

Despite the fact that RPG panels are a material with excellent technical characteristics, they are not used universally. This is due to the rather high price, which is quite justified.

Advantages and disadvantages of RPG panels

Panels with a waterproofed surface have a lot of positive qualities. In particular, this is high adhesion to concrete, fire resistance, reliable heat and waterproofing (material immersed in liquid remains practically dry, since it absorbs 0.1% per day). It is also worth noting the following advantages of RPG panels:

- flexibility, allowing you to create frameless structures and produce surface finishes of almost any configuration;

- low level of vapor permeability, which excludes the formation of condensation under the panels;

- low weight, which with a material thickness of 10 mm is about 2 kg / m²;

- non-susceptibility to the formation of fungi and mold;

- resistance to temperature extremes;

- the ability to use to create frameless structures;

- ease and simplicity of panel installation, which even a person without construction experience can handle;

- environmental friendliness and hypoallergenicity;

- high resistance to mechanical stress;

- durability of the material, the service life of which reaches 50 years.

As you can see, RPG panels have a lot of positive qualities, and only the high price of the material can be attributed to the disadvantages.

Assortment of panels and their application depending on the thickness

The assortment of RPG panels is represented by slabs with a thickness of 4, 6, 10, 20, 30, 40, 50, 60, 80 and 100 mm. The area of application of the material largely depends on this indicator.

RPG 10 mm

The thinnest panels are used to insulate and level floors, ceilings and walls. They are also used for waterproofing shower cabins and as a rough base for warm floors. RPG 10mm panels are often used as a base for finishing. Installation is carried out using PU polyurethane glue, dowels with screws or a combination of these.

Despite the fact that the panels are not afraid of moisture, the places of their connection with each other and adjoining to other structures require additional waterproofing and gluing with a special tape. The surface of the material does not need plastering before painting or laying porcelain stoneware tiles. Due to its insignificant thickness, the RPG 10 mm cannot be used to create frameless structures.

Before the finish painting or gluing wallpaper it is necessary to stick on the surface of the panels glass canvas and execute putty work.

Using RPG panels 20mm

These panels are more functional than the previous version. They are suitable for additional internal insulation of apartments and houses, arrangement of a bathroom in wooden buildings, creating external slopes, leveling walls and ceilings with simultaneous insulation. Also from RPG 20 mm it is possible to create closable boxes of any shape.

Installation of slabs and waterproofing of joints is carried out in the same way as in the case of 10 mm panels. However, a material of this thickness is not suitable for arranging base floors and creating frameless partitions.

Slabs with a waterproofing layer of 30-40 mm

RPG boards with a thickness of 30-40 mm can be used for external insulation of walls in brick, timber and panel houses. The material is suitable for arranging base floors, creating boxes for ventilation and utilities. RPG panels 30-40 mm can be used to create frameless under-bath screens, pallets, podiums and columns.

Expansion with RPG panels 50-60mm

Panels of this thickness can be used for the manufacture of interior partitions and frameless steps. They are also used to create original furniture of various configurations for SPA salons, saunas and large bathrooms. By the way, despite the rigidity of the panels, sit on couches or sofas made of this material is quite comfortable, since they return the heat of the human body even in cool the room.

Waterproofing panels RPG 80-100 mm

Polystyrene boards with a waterproofing layer 80-100 mm thick can be considered a full-fledged building material. They are used to create interior partitions, small pools, fountains and even when arranging the roof. It is also allowed to erect light utility buildings.

Installation features

RPG panels are so easy to install that even a person with no construction experience can handle it. The material is made of polystyrene sheets with dimensions of 2500 × 600 mm and various thicknesses. They have a tongue-and-groove or quarter-type locking connection, which can be compared with the clapboard or laminated board of the first generation.

If necessary, the slabs can be easily cut or bent to give the structure the desired configuration. The inner side of the panels remains porous, while the outer surface is reinforced with fiberglass mesh and a special polymer-cement composition.

Installation of panels with a waterproofing layer is carried out using:

- special adhesives - dry or ready-made;

- polyurethane foam pro-series;

- "Liquid nails" for expanded polystyrene;

- dowel-nails systems.

A few words in conclusion

RPG panels with a waterproofing surface are widely used in construction and renovation work. If it were not for the high price of the material, then it would have replaced plaster or drywall sheets long ago.

We hope that our article was useful to you, and you learned something new for yourself. We are waiting for your feedback in the comment form.