The bath takes a special place in the heart of the Russian person. Our mentality is based on the perception of the bath not just as a banal bathing room, but as a kind of sacred structure where the body and soul are cleansed. And what is needed for this? Of course, as our ancestors used to say, "light steam", which can only be achieved by observing the ideal balance of temperature and humidity. In this matter, it is absolutely unimportant what type of bath you are a fan of, because the main principle for all are one - in the interior there should be a favorable microclimate and a comfortable temperature mode.

Read in the article

- 1 It's a bathhouse! Does she need insulation?

- 2 What is suitable for bath insulation?

- 3 Are there universal heaters for baths made of wood, brick, aerated concrete?

- 4 The best PIR insulation and its benefits

- 5 How much insulation do you need specifically?

- 6 Installation work

It's a bathhouse! Does she need insulation?

Perhaps we all agree that there is nothing worse than a bath, from which all the steam evaporates in an instant. Therefore, during its construction and equipment, it is so important to pay special attention to thermal insulation. After all, only with the help of a multi-layer sealed profile made of wind, hydro, vapor barrier and insulation the so-called "thermos" effect is achieved, which is guaranteed to eliminate the problem of rapid "cooling" baths.

Thanks to high-quality thermal insulation, you can solve a number of tasks at once, including:

- quick warm-up and temperature maintenance (without any extra effort on your part) for a long time;

- minimization of heating costs by reducing the heat loss of the building;

- and an increase in the service life of the entire building.

You will appreciate the charm of thermal insulation in cold weather. For example, it will take at least 4 hours to warm up an uninsulated bath, while you have to constantly monitor the temperature and be distracted by throwing firewood. Baths with well-planned and equipped thermal insulation, even in the most dashing frost, are heated faster, which allows you not only to save time, energy and fuel, but also gives you the opportunity to qualitatively rest your soul and body.

Some leave timber baths without internal insulation, fearing to disrupt the natural microclimate. Of course, if your bath is a wooden structure with thick walls, which is used only in the warm season, then such a measure is adequate. But in winter, a long log fire is dangerous - the wood heats up a lot, and already at a temperature of 300 ° C there is a real threat of fire.

Due to strong temperature changes and excessive humidity, the baths are prone to fungus and efflorescence, which have an adverse effect both on human health and on all structural elements of a structure in the whole. But good insulation and vapor barrier will cope with this.

What is suitable for bath insulation?

It is worth considering the material of the walls and the purpose of the room. The main criteria that are important when choosing insulation are as follows:

- safety (no toxic substances should be released when heated);

- no deformation at extreme temperatures and high humidity (tightness can only be achieved if there is no shrinkage);

- low hygroscopicity (the material should not absorb moisture and promote the formation of mold and other microorganisms);

- ease of installation;

- price.

For log cabins, natural mezhventsovy heaters (roll felt, jute, tow or moss) are more suitable due to their environmental friendliness and efficiency, but it is worth remembering that they are flammable and hygroscopic.

Are there universal heaters for baths made of wood, brick, aerated concrete?

Yes. And not alone.

- Mineral wool. They are suitable for thermal insulation of all rooms. Despite environmental friendliness and fire safety, this material is considered "capricious", because during its installation you need comply with certain requirements (staggered joint laying, indispensable vapor barrier protection with a distance of 50 mm between layers etc.).

Mineral wool insulation - Styrofoam. It is a heater in the form of slabs, used for insulation in almost the entire bath, except for the steam room. The fact is that when heated, the foam not only emits toxic substances, but also flammable. In addition, unfortunately, there is one more disadvantage - rodents, which spoil the material from the inside.

Styrofoam - Foam glass. These are blocks with a cellular structure, the main advantages of which are chemical and biological resistance, as well as fire safety. But this is an expensive building material, for the installation of which you will need to hire a professional team.

Foam glass - Extruded expanded polystyrene. Lightweight and durable material, which is an improved version of foam. It is suitable for insulating any premises (but it is still not recommended to use it in a steam room, because the permitted temperature of use is the same as for foam).

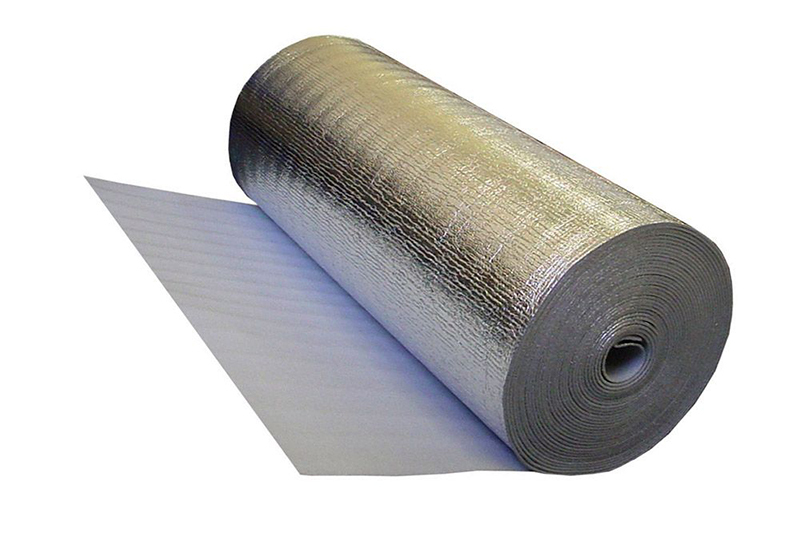

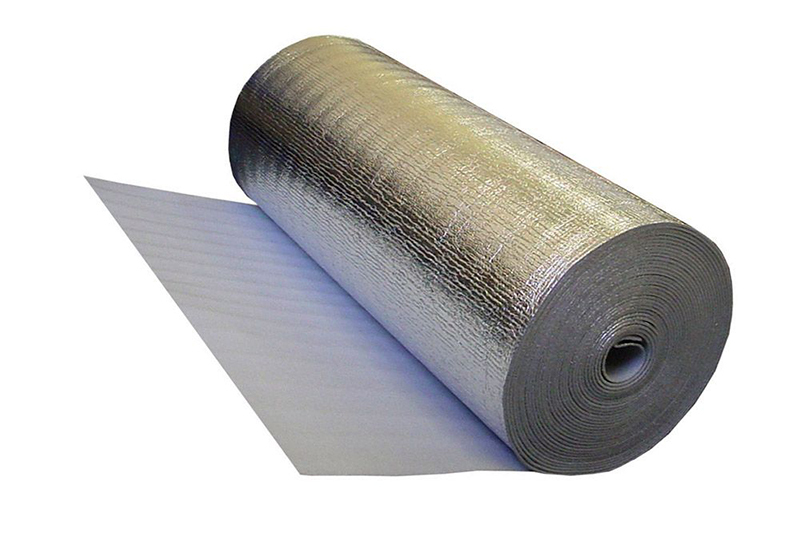

Extruded polystyrene foam - Foil insulation, which are created on the basis of mineral wool or polyisocyanurate foam and covered with aluminum foil (hence the name). The main feature of the material is a reflective layer, which allows you to quickly warm up the room and retain heat for a long time.

Foil insulation

The most popular today are precisely foil insulation. Consumers give them their choice for the speed and ease of installation, as well as for environmental safety. These qualities make it possible to use such heaters both during new construction and when rebuilding baths and saunas (even if there are walls adjacent to the residential part of the house).

An independent category of foil-clad heaters includes PIR heat-insulating plates.

The best PIR insulation and its benefits

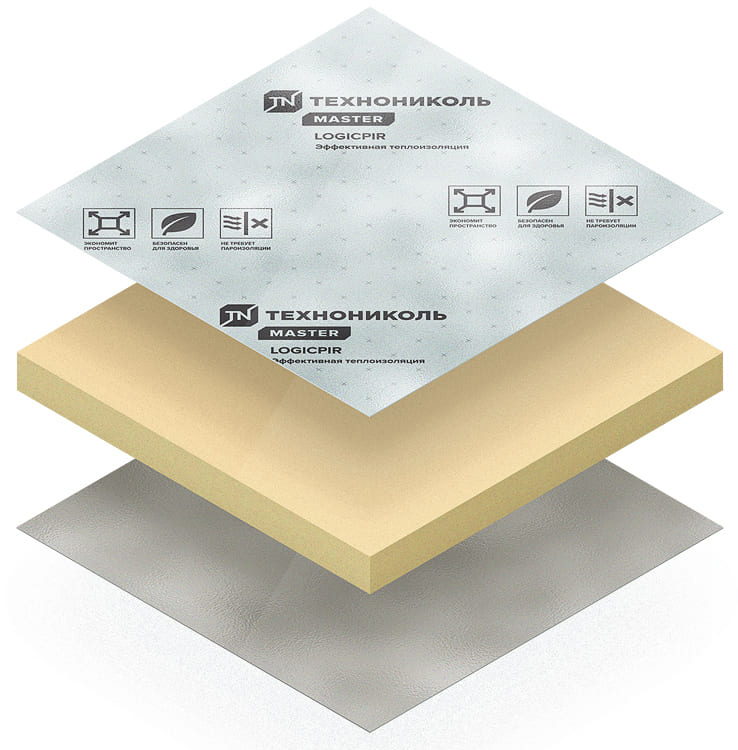

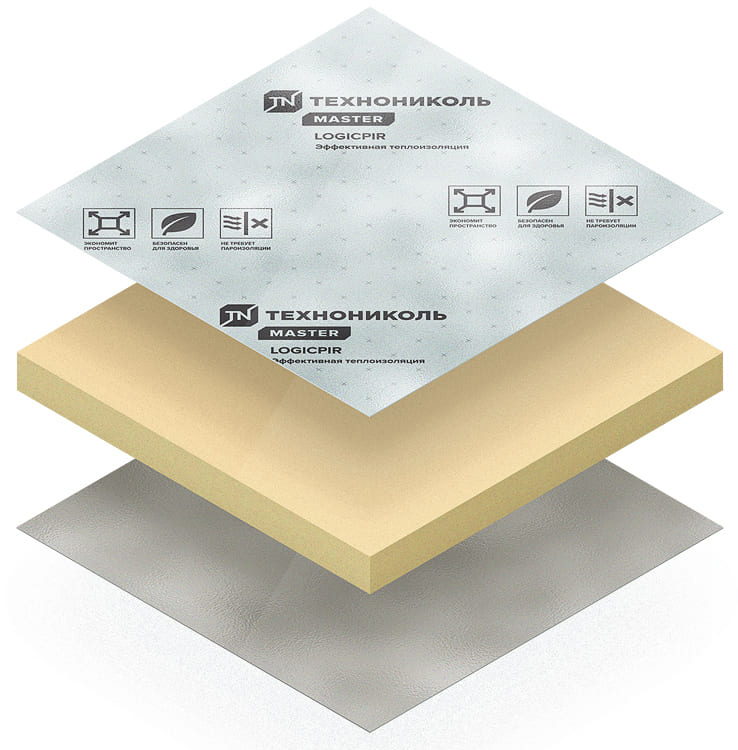

Three-layer plates stand out among foil-clad thermal insulation materials due to their increased energy efficiency. LOGICPIR Bath from company TECHNONICOL. A uniquely low thermal conductivity - 0.022 W / (m * K) - is ensured due to the special structure of the insulation:

- the core is a rigid polyurethane foam with a closed cell structure. The cells are filled with permanent gas inside;

- aluminum foil vapor and waterproof on both sides of the core. The reflectivity of the foil is within 95-95%, and the emissivity of the surface is no more than 0.5 W / m2TO4.

Now the effect, which previously required 2-3 layers of mineral wool, can be achieved with just one layer of LOGICPIR Bath.

In addition to the remarkable thermal characteristics of TECHNONICOL PIR slabs, they have a small thickness (20-50 mm) and weight (one slab weighs 500 g). It turns out that thanks to them, it is possible not only to reduce the thickness of the heat-insulating layer, saving useful space, but also to reduce the load on the supporting elements of the structure.

How much insulation do you need specifically?

Calculation of the required number of packages of LOGICPIR Sauna boards depends on the total area (S) of the surfaces to be insulated.

The number of insulation sheets corresponds to the area of the walls divided by the area of one sheet (S walls / S one sheet).

The area of one plate:

- with L-shaped edge - 0.69 m2 (1185 x 585 mm);

- with a straight edge - 0.72 m2 (1200 x 600 mm).

Packages LOGICPIR Bath with L-shaped edge contain 8, 10 and 13 plates, and with a flat end - 8 pieces.

Divide the figure obtained during the calculations by the number of sheets in one pack, and round the final result up. Now you know how many packs you need.

Installation work

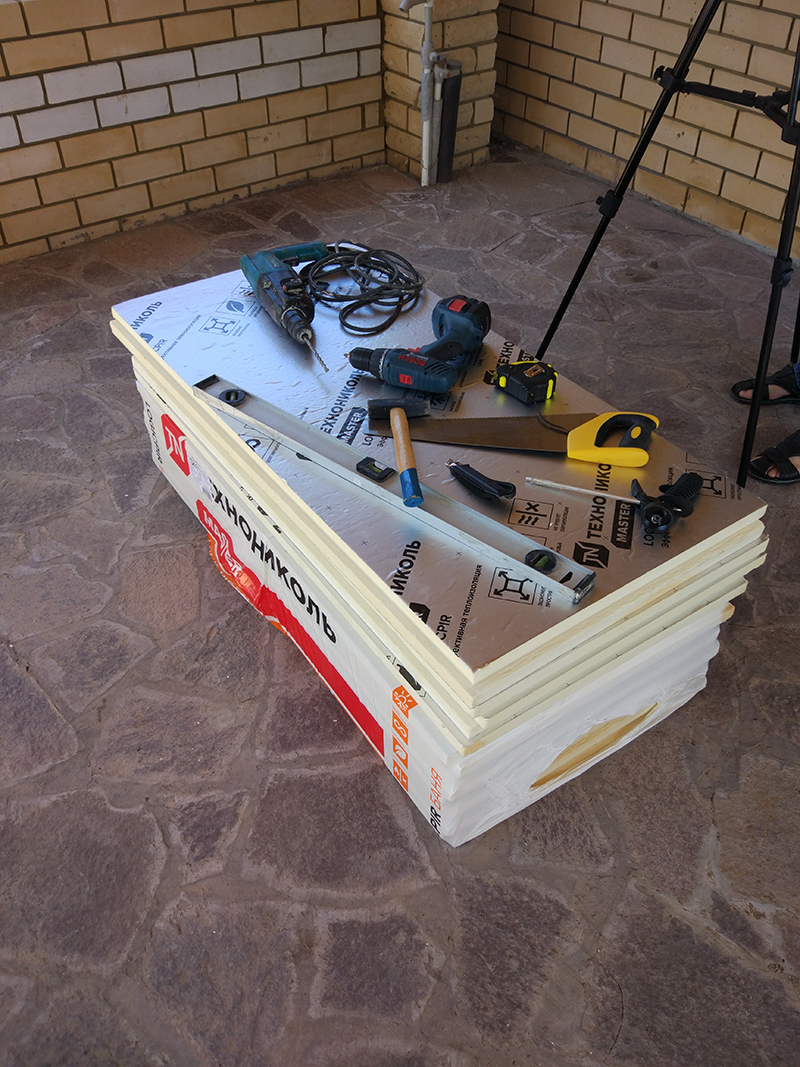

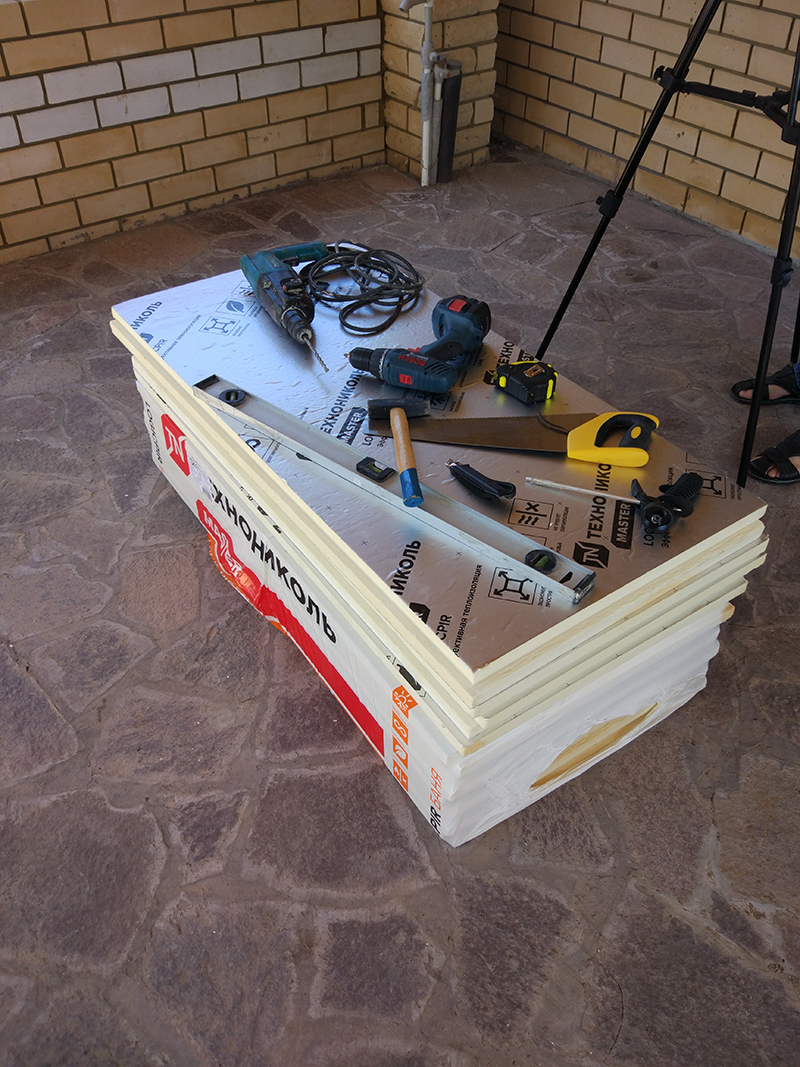

A big plus is that installation work can be carried out throughout the year, regardless of weather conditions. It is also worth noting that the material does not require special storage conditions - you can easily fold packages horizontally both indoors and outdoors under an awning or roof.

Installation work does not require special knowledge or expensive professional tools. Therefore, by choosing LOGICPIR insulation, you save on hiring a construction team. Great bonus, right? The specialists of the TECHNONICOL company will collect all the necessary materials, taking into account all the features of a specific insulated object, so that you do not have any difficulties during construction work.

Installation is carried out in four stages.

Your first step is to check the surface for fixing the insulation boards. It should be firm, flat and dry.

After making sure that there are no gaps of more than 5 mm (a two-meter rail will help you here), feel free to proceed to direct fixation of the insulation with LOGICPIR glue-foam, which will maintain its integrity and tightness constructions. If you have excess insulation, then it is easy to cut them off with a construction knife.

We fix the insulation on the wooden ceiling with self-tapping screws (the recommended distance between them is at least 400 mm).

Do not forget to place the slabs with a gap between the seams so that the corners are not adjacent to each other.

The next step is to create an airtight vapor barrier. LOGIPIR boards are available with flat and L-shaped edges, which are equally tightly joined. All edges and heads of the screwed-in self-tapping screws must be well glued with TECHNONICOL elastic waterproofing tape, which will protect against the penetration of condensate. It retains its properties at large temperature fluctuations, so do not be afraid of delamination. The most important rule is to start gluing the tape when the air temperature is above + 5 ° C.

Finishing work is the final phase. Often deciduous lining is used for decoration. The lamellas are fixed on top of the wooden guides with metal fasteners perpendicular to the crate. This creates a space for ventilation between the surface of the foil and the clapboard. Experts recommend leaving small gaps near the ceiling and floor, which will then be covered with a baseboard.

At the end of the work, the surface can be treated with linseed oil, wax antiseptic, or even left without impregnation, because the tree has an excellent texture and an amazing aroma in itself.

Not sure which insulation material to choose? Remember everything we talked about above.

Modern and high-tech slabs LOGICPIR Bath from the international manufacturer of building materials TECHNONICOL are rightfully the best in existence today.

Energy efficiency, durability, non-susceptibility to the spread of fungus remain throughout the entire service life (more than 50 years). And the fire safety of the material is generally beyond praise! LOGICPIR boards prevent the spread of flame - when ignited, the outer layer is charred, forming a porous carbon matrix, and "self-extinguishing".

But what deserves special attention is the absolute environmental safety of LOGICPIR, which was confirmed during tests at the Institute of Chemistry of Solutions of the Russian Academy of Sciences. Experimentally, researchers have proved the complete absence of toxic substances in the conditions of baths and saunas. Thus, LOGICPIR Bath complies with GOST R for reflective insulation.

Take advantage of modern technical advances to insulate a bath or sauna with LOGICPIR Sauna stoves. You will not be able to remain indifferent and you will enjoy the result for many years!

ONLY IN JULY, AUGUST AND SEPTEMBER 2020 YOU CAN GET A 10% DISCOUNT * BY A PROMO CODE HOUSECHIEF ON THE FOLLOWING LOGICPIR HEATERS FROM TECHNONICOL COMPANY:

| Name | Product code |

| LOGICPIR BATH L-1190Х590Х50 (5 PLATES, 3.51 SQ.M) | 651243 |

| LOGICPIR Floors FL / FL G4 L-1190 × 590x50 | 650653 |

| LOGICPIR L-1190Х590Х30 (8 PLATES, 5.62 SQ.M) | 650050 |

| LOGICPIR Balcony L-1190 × 590x40 (6 slabs, 4.16 sq.m.) | 651854 |

* In order to receive a 10% discount, you need to register in the TechnoNIKOL online store.

MATERIAL PREPARED WITH SUPPORT

The bath takes a special place in the heart of the Russian person. Our mentality is based on the perception of the bath not just as a banal bathing room, but as a kind of sacred structure where the body and soul are cleansed. And what is needed for this? Of course, as our ancestors used to say, "light steam", which can only be achieved by observing the ideal balance of temperature and humidity. In this matter, it is absolutely unimportant what type of bath you are a fan of, because the main principle for all are one - in the interior there should be a favorable microclimate and a comfortable temperature mode.

Read in the article

- 1 It's a bathhouse! Does she need insulation?

- 2 What is suitable for bath insulation?

- 3 Are there universal heaters for baths made of wood, brick, aerated concrete?

- 4 The best PIR insulation and its benefits

- 5 How much insulation do you need specifically?

- 6 Installation work

It's a bathhouse! Does she need insulation?

Perhaps we all agree that there is nothing worse than a bath, from which all the steam evaporates in an instant. Therefore, during its construction and equipment, it is so important to pay special attention to thermal insulation. After all, only with the help of a multi-layer sealed profile made of wind, hydro, vapor barrier and insulation the so-called "thermos" effect is achieved, which is guaranteed to eliminate the problem of rapid "cooling" baths.

Thanks to high-quality thermal insulation, you can solve a number of tasks at once, including:

- quick warm-up and temperature maintenance (without any extra effort on your part) for a long time;

- minimization of heating costs by reducing the heat loss of the building;

- and an increase in the service life of the entire building.

You will appreciate the charm of thermal insulation in cold weather. For example, it will take at least 4 hours to warm up an uninsulated bath, while you have to constantly monitor the temperature and be distracted by throwing firewood. Baths with well-planned and equipped thermal insulation, even in the most dashing frost, are heated faster, which allows you not only to save time, energy and fuel, but also gives you the opportunity to qualitatively rest your soul and body.

Some leave timber baths without internal insulation, fearing to disrupt the natural microclimate. Of course, if your bath is a wooden structure with thick walls, which is used only in the warm season, then such a measure is adequate. But in winter, a long log fire is dangerous - the wood heats up a lot, and already at a temperature of 300 ° C there is a real threat of fire.

Due to strong temperature changes and excessive humidity, the baths are prone to fungus and efflorescence, which have an adverse effect both on human health and on all structural elements of a structure in the whole. But good insulation and vapor barrier will cope with this.

What is suitable for bath insulation?

It is worth considering the material of the walls and the purpose of the room. The main criteria that are important when choosing insulation are as follows:

- safety (no toxic substances should be released when heated);

- no deformation at extreme temperatures and high humidity (tightness can only be achieved if there is no shrinkage);

- low hygroscopicity (the material should not absorb moisture and promote the formation of mold and other microorganisms);

- ease of installation;

- price.

For log cabins, natural mezhventsovy heaters (roll felt, jute, tow or moss) are more suitable due to their environmental friendliness and efficiency, but it is worth remembering that they are flammable and hygroscopic.

Are there universal heaters for baths made of wood, brick, aerated concrete?

Yes. And not alone.

- Mineral wool. They are suitable for thermal insulation of all rooms. Despite environmental friendliness and fire safety, this material is considered "capricious", because during its installation you need comply with certain requirements (staggered joint laying, indispensable vapor barrier protection with a distance of 50 mm between layers etc.).

Mineral wool insulation - Styrofoam. It is a heater in the form of slabs, used for insulation in almost the entire bath, except for the steam room. The fact is that when heated, the foam not only emits toxic substances, but also flammable. In addition, unfortunately, there is one more disadvantage - rodents, which spoil the material from the inside.

Styrofoam - Foam glass. These are blocks with a cellular structure, the main advantages of which are chemical and biological resistance, as well as fire safety. But this is an expensive building material, for the installation of which you will need to hire a professional team.

Foam glass - Extruded expanded polystyrene. Lightweight and durable material, which is an improved version of foam. It is suitable for insulating any premises (but it is still not recommended to use it in a steam room, because the permitted temperature of use is the same as for foam).

Extruded polystyrene foam - Foil insulation, which are created on the basis of mineral wool or polyisocyanurate foam and covered with aluminum foil (hence the name). The main feature of the material is a reflective layer, which allows you to quickly warm up the room and retain heat for a long time.

Foil insulation

The most popular today are precisely foil insulation. Consumers give them their choice for the speed and ease of installation, as well as for environmental safety. These qualities make it possible to use such heaters both during new construction and when rebuilding baths and saunas (even if there are walls adjacent to the residential part of the house).

An independent category of foil-clad heaters includes PIR heat-insulating plates.

The best PIR insulation and its benefits

Three-layer plates stand out among foil-clad thermal insulation materials due to their increased energy efficiency. LOGICPIR Bath from company TECHNONICOL. A uniquely low thermal conductivity - 0.022 W / (m * K) - is ensured due to the special structure of the insulation:

- the core is a rigid polyurethane foam with a closed cell structure. The cells are filled with permanent gas inside;

- aluminum foil vapor and waterproof on both sides of the core. The reflectivity of the foil is within 95-95%, and the emissivity of the surface is no more than 0.5 W / m2TO4.

Now the effect, which previously required 2-3 layers of mineral wool, can be achieved with just one layer of LOGICPIR Bath.

In addition to the remarkable thermal characteristics of TECHNONICOL PIR slabs, they have a small thickness (20-50 mm) and weight (one slab weighs 500 g). It turns out that thanks to them, it is possible not only to reduce the thickness of the heat-insulating layer, saving useful space, but also to reduce the load on the supporting elements of the structure.

How much insulation do you need specifically?

Calculation of the required number of packages of LOGICPIR Sauna boards depends on the total area (S) of the surfaces to be insulated.

The number of insulation sheets corresponds to the area of the walls divided by the area of one sheet (S walls / S one sheet).

The area of one plate:

- with L-shaped edge - 0.69 m2 (1185 x 585 mm);

- with a straight edge - 0.72 m2 (1200 x 600 mm).

Packages LOGICPIR Bath with L-shaped edge contain 8, 10 and 13 plates, and with a flat end - 8 pieces.

Divide the figure obtained during the calculations by the number of sheets in one pack, and round the final result up. Now you know how many packs you need.

Installation work

A big plus is that installation work can be carried out throughout the year, regardless of weather conditions. It is also worth noting that the material does not require special storage conditions - you can easily fold packages horizontally both indoors and outdoors under an awning or roof.

Installation work does not require special knowledge or expensive professional tools. Therefore, by choosing LOGICPIR insulation, you save on hiring a construction team. Great bonus, right? The specialists of the TECHNONICOL company will collect all the necessary materials, taking into account all the features of a specific insulated object, so that you do not have any difficulties during construction work.

Installation is carried out in four stages.

Your first step is to check the surface for fixing the insulation boards. It should be firm, flat and dry.

After making sure that there are no gaps of more than 5 mm (a two-meter rail will help you here), feel free to proceed to direct fixation of the insulation with LOGICPIR glue-foam, which will maintain its integrity and tightness constructions. If you have excess insulation, then it is easy to cut them off with a construction knife.

We fix the insulation on the wooden ceiling with self-tapping screws (the recommended distance between them is at least 400 mm).

Do not forget to place the slabs with a gap between the seams so that the corners are not adjacent to each other.

The next step is to create an airtight vapor barrier. LOGIPIR boards are available with flat and L-shaped edges, which are equally tightly joined. All edges and heads of the screwed-in self-tapping screws must be well glued with TECHNONICOL elastic waterproofing tape, which will protect against the penetration of condensate. It retains its properties at large temperature fluctuations, so do not be afraid of delamination. The most important rule is to start gluing the tape when the air temperature is above + 5 ° C.

Finishing work is the final phase. Often deciduous lining is used for decoration. The lamellas are fixed on top of the wooden guides with metal fasteners perpendicular to the crate. This creates a space for ventilation between the surface of the foil and the clapboard. Experts recommend leaving small gaps near the ceiling and floor, which will then be covered with a baseboard.

At the end of the work, the surface can be treated with linseed oil, wax antiseptic, or even left without impregnation, because the tree has an excellent texture and an amazing aroma in itself.

Not sure which insulation material to choose? Remember everything we talked about above.

Modern and high-tech slabs LOGICPIR Bath from the international manufacturer of building materials TECHNONICOL are rightfully the best in existence today.

Energy efficiency, durability, non-susceptibility to the spread of fungus remain throughout the entire service life (more than 50 years). And the fire safety of the material is generally beyond praise! LOGICPIR boards prevent the spread of flame - when ignited, the outer layer is charred, forming a porous carbon matrix, and "self-extinguishing".

But what deserves special attention is the absolute environmental safety of LOGICPIR, which was confirmed during tests at the Institute of Chemistry of Solutions of the Russian Academy of Sciences. Experimentally, researchers have proved the complete absence of toxic substances in the conditions of baths and saunas. Thus, LOGICPIR Bath complies with GOST R for reflective insulation.

Take advantage of modern technical advances to insulate a bath or sauna with LOGICPIR Sauna stoves. You will not be able to remain indifferent and you will enjoy the result for many years!

ONLY IN JULY, AUGUST AND SEPTEMBER 2020 YOU CAN GET A 10% DISCOUNT * BY A PROMO CODE HOUSECHIEF ON THE FOLLOWING LOGICPIR HEATERS FROM TECHNONICOL COMPANY:

| Name | Product code |

| LOGICPIR BATH L-1190Х590Х50 (5 PLATES, 3.51 SQ.M) | 651243 |

| LOGICPIR Floors FL / FL G4 L-1190 × 590x50 | 650653 |

| LOGICPIR L-1190Х590Х30 (8 PLATES, 5.62 SQ.M) | 650050 |

| LOGICPIR Balcony L-1190 × 590x40 (6 slabs, 4.16 sq.m.) | 651854 |

* In order to receive a 10% discount, you need to register in the TechnoNIKOL online store.

MATERIAL PREPARED WITH SUPPORT