In this article, we will look at 5 parameters that affect the energy efficiency of the walls of a residential building. After all, everyone who plans to build their own house thinks about making it warm, reliable, and spending as little money as possible on its maintenance and heating.

Read in the article

- 1 Wall material and thickness

- 2 Masonry joint material

- 3 Reinforcement material

- 4 Jumpers and armo-belts

- 5 Cold bridges

Wall material and thickness

Walls are the largest construction in terms of area in a residential building. And this means that if you do not pay due attention to their energy efficiency, then it is through them that the main heat losses will pass (up to 35%).

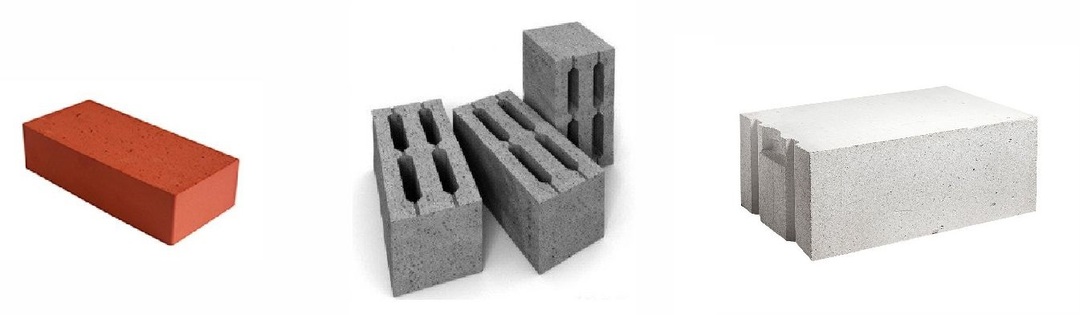

The most popular materials for building a house in the Tyumen region are: ceramic bricks, expanded clay blocks and aerated concrete. When choosing a material for a future home, you need to pay attention to its characteristics.

| Index | Ceramic brick | Expanded clay concrete block | Aerated concrete block |

| Compound | Clay, dye, water | Cement, expanded clay, sand, water | Gypsum, lime, cement, sand, water |

| Strength grade, M | 150 | 50 | 35 |

| Dry heat conductivity, W / (m ° С) | 0,42 | 0,36 | 0,11 |

| Frost resistance, F (cycles) | 75 | 50 | 75 |

| Density, kg / m3 | 1400 | 1100 | 500 |

| Deviation of geometrical dimensions, mm. | ± 7 mm | ± 7 mm | ± 2 mm |

| Minimum permissible wall thickness without insulation (for the South of the Tyumen region), Rmin = 2.25 | 380 mm brick + 50 insulation (R = 2.25) | 190 + 190 mm. block + 50 mm. insulation (R = 2.43) | 400 mm block (R = 3.00) No insulation needed |

* Data from manufacturers' websites.

Masonry joint material

Depending on the material used for the masonry joint, its thickness varies from 1 to 15 mm. And the thermal conductivity of masonry mortar is 5-10 times higher than the thermal conductivity of energy-efficient wall materials. Accordingly, the energy efficiency of the masonry as a whole will also depend on how thin and "warm" the seam will be.

There are three main types of masonry seams:

- Cement-sand mortar (thickness 10-15 mm)

- Thin-seam mineral glue (seam thickness 2-3 mm)

- Polyurethane foam adhesive (joint thickness up to 1 mm)

Cement-sand mortar is a mixture of sand and cement. Usually builders buy sand and cement machine in bags. It is inexpensive, but difficult to mix and requires a concrete mixer. And it is also applied with a thick layer of 10-15 mm, which forms large bridges of cold.

Fine-seam mineral glue - sold in bags ready-made, it remains to add water and mix with a construction mixer. Due to the optimal ratio of sand, cement and additives, it is easy to mix and apply in a thin layer of 2-3 mm.

Polyurethane foam adhesive is gaining popularity among builders due to clean masonry and the absence of wet processes, high foam yield from one cylinder and high masonry speed. Also, the thickness of the glue is less than 1 mm. - this allows you to build almost uniform walls without cold bridges. At the same time, the disadvantages include the high price, quick setting of blocks, restrictions on laying in the winter (up to -15 ° C).

Reinforcement material

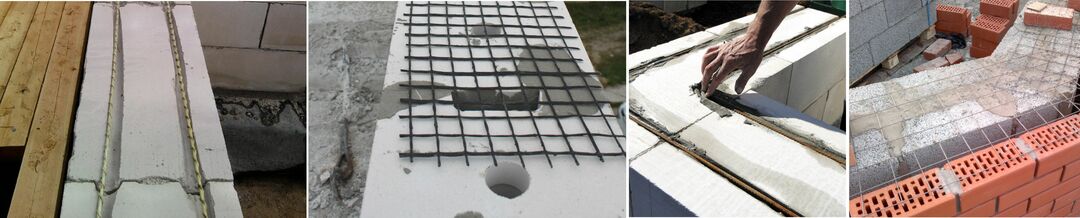

Now, in the construction of walls of residential individual houses, in the overwhelming majority of cases, two types of reinforcement are used: bar reinforcement and mesh. Each of these types of reinforcement can also be of two types: metal and composite (for example, basalt).

Usually, the reinforcement of the masonry walls is performed every 2-3 rows of masonry. And this is a fairly large percentage of "inclusions" in the masonry. For comparison, the difference in thermal conductivity between metal and basalt rods is more than 100 times! (0.35 W / m2* ° С against 48 W / m2* ° C). In simple terms, steel reinforcement and mesh are cold materials that conduct heat quickly.

Steel mesh is inexpensive, but at the same time it is heavy, requires immersion in a thick layer of mortar, which increases the thermal conductivity of the masonry. Steel reinforcement allows you to create frames of any shape due to its flexibility, but at the same time it has a lot of weight and also has a high thermal conductivity.

Basalt mesh has light weight, ease of transportation and safety in installation, as well as low thermal conductivity, which solves the problem of cold bridges. Basalt rebar also has low thermal conductivity, light weight, but lacks flexibility.

Jumpers and armo-belts

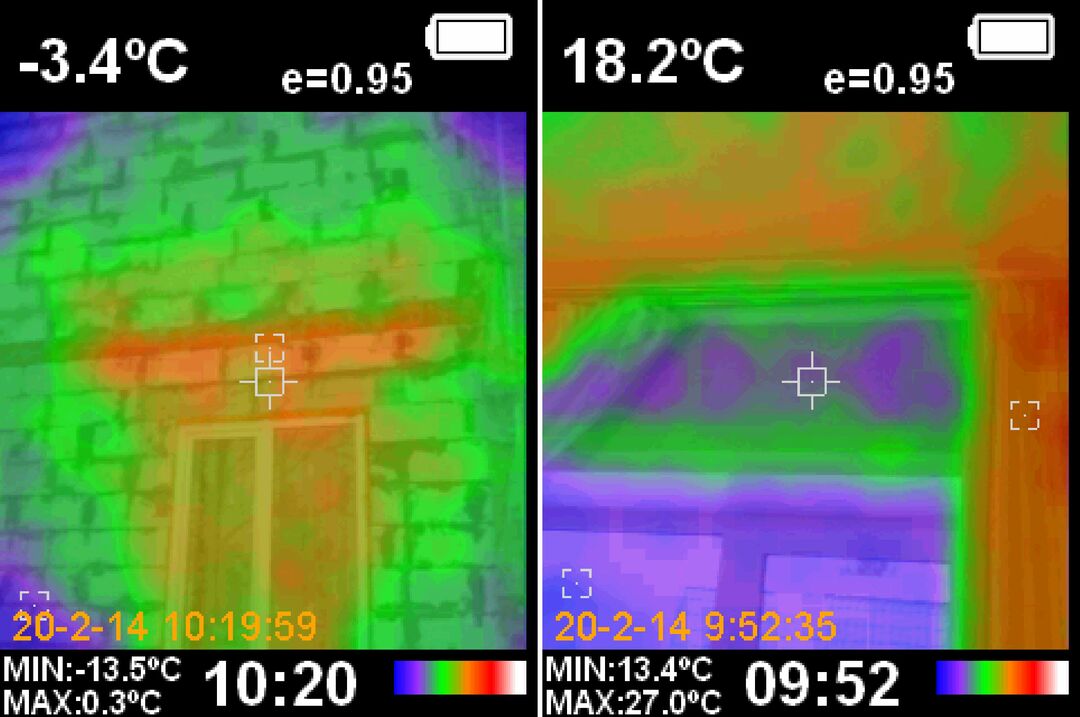

The material of the jumper device can also be different. If a reinforced concrete lintel is laid in an energy-saving wall, it will be a huge cold bridge, due to which the wall in this place will constantly freeze through, condensation will accumulate on it and, over time, mold may appear and etc.

To avoid this, the material of the lintel and the armored belt, as well as their design, must be no less warm than the walls themselves.

In the images of the thermal imager (on the left is a view from the street: the red zone, where heat escapes through the reinforced concrete jumper. On the right is a view from the house: cold zones - a window and a lintel above it).

When building houses from aerated blocks, light warm lintels (in the shape of the letter U) are used, which are created specifically for joint use with the block itself. But nevertheless, they require additional insulation, but to a much lesser extent than reinforced concrete. Typically, insulation is embedded inside such a block, and then filled with concrete.

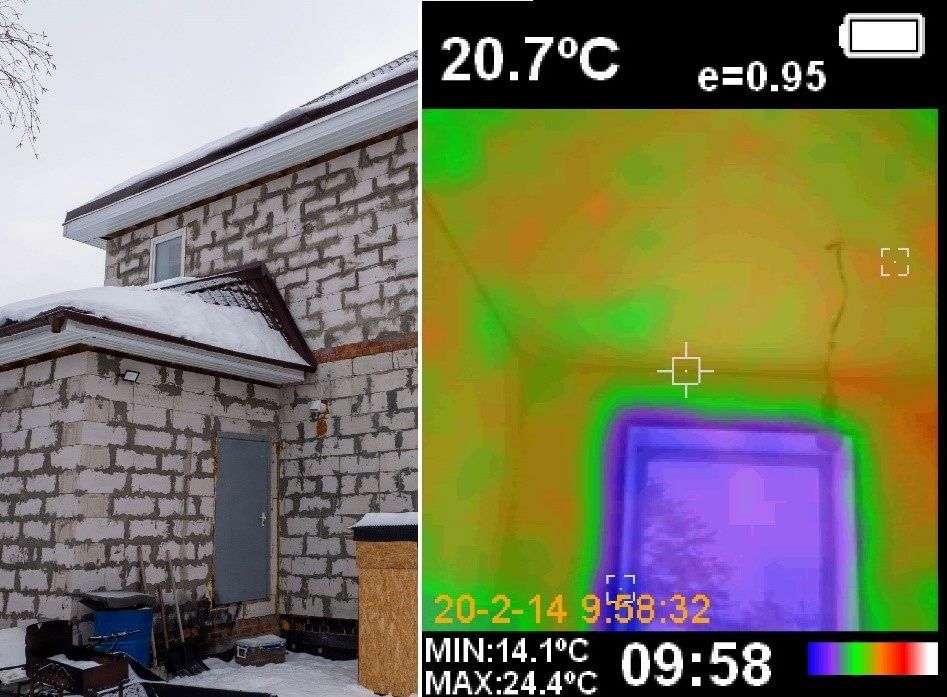

In the images of the thermal imager (on the left is a view from the street to the 2nd floor, where you can see that the lintel above the window is made of aerated concrete U-block. On the right is a view from the house: the cold zone of the window, but a uniformly distributed thermal field over the entire surface of the ceiling, walls and window lintel).

Cold bridges

As mentioned above, the more homogeneous the wall, the warmer it is. This is also prescribed in the regulatory documentation (joint venture Thermal protection of buildings). Each additional inclusion in the wall violates its uniformity. If the material from which the wall is made is not warm enough to comply with all the required standards, then it will have to be additionally insulated. And any kind of insulation must be mechanically fastened. The number of such fasteners in the facade can be up to 10 pieces for each square meter of the wall, and each of these elements is a cold bridge. That is why single-layer walls are so appreciated. In addition, in order to build a warm house, you do not need to spend money on insulation and work on its installation, you can simply correctly calculate the required wall thickness, which will correspond to the required values.

Thus, we examined 5 parameters that affect the energy efficiency of the walls of a residential building. The correctness of their choice will affect the costs of the construction itself and heating in the future.

So, you need to pay attention to:

- Physical and mechanical properties of the wall material.

- Building standards for wall thickness.

- Masonry materials and their characteristics.

- Design features of the construction of window, door lintels and reinforcement belts in front of the ceilings.

- Other materials used for construction.