There are a lot of articles with similar names on the net. However, some can simply lead to serious trouble. So our online magazine decided not to leave this question unanswered, but to try to figure out which of the posted on the network - true, but which articles should be excluded from the list of read at all, so as not to mislead novice home craftsmen. Today we'll talk about installation electrical wiring with the possibility of subsequent repair of one or another unit.

Read in the article

- 1 The first thing to look out for

- 1.1 Important nuances when laying a wire in a strobe

- 1.2 Features of the connection of cores in the junction box

- 1.3 Screw pads and their use

- 1.4 WAGO: to use or not

- 2 WAGO series for faster installation and easier repairs

- 3 A few words about safety during electrical installation

- 4 Finally

The first thing to look out for

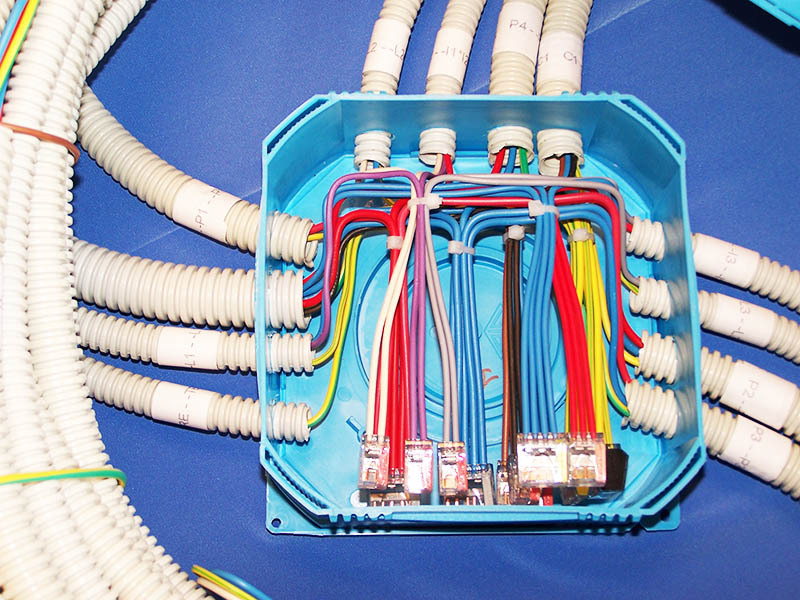

Surely everyone understands that above each socket or switch a junction box must be installed. It is necessary to be able to connect separate or combined power points. Here, many argue as to how it is correct: it is soldering, distributing (KR) or branching. It is worth clarifying that, in fact, this is an electrical box, which is also an installation box (KU). It turns out that both of these types, both KR and KU, refer to electrical or junction boxes. So, it would be correct to call it distributive.

Important nuances when laying a wire in a strobe

The main task is to ensure that the conductors inserted into the junction box are not too short. It is necessary to calculate so that there is enough for the connection, and also there is a margin of at least 5-7 cm.

It makes sense to lay vertical tails that go to sockets and switches in a corrugation. Many will ask what it is for. Everything is very simple. For example, an outlet that burns out several times (after heating from a faulty plug), and there is no core supply. Corrugation will make it possible to replace the entire tail. Well, all horizontal veins can be covered without an additional "cover".

Features of the connection of cores in the junction box

According to the rules, twisting is prohibited in the box. In fact, this is done almost everywhere. The same can be said for soldering. If it is decided to twist, then the bare ends of the veins should be about 5 cm, and the connection itself should be as tight as possible. When planning the subsequent soldering, the exposed parts of the cores are pre-tinned. After twisting the veins, it only remains to warm them up.

Related article:

In the publication, we will consider the main materials used in insulating connections in the junction box: PVC insulating tape, cotton insulating tape, heat shrink tubing and other insulating tapes used in everyday life, as well as connecting wires in a box without additional insulation.

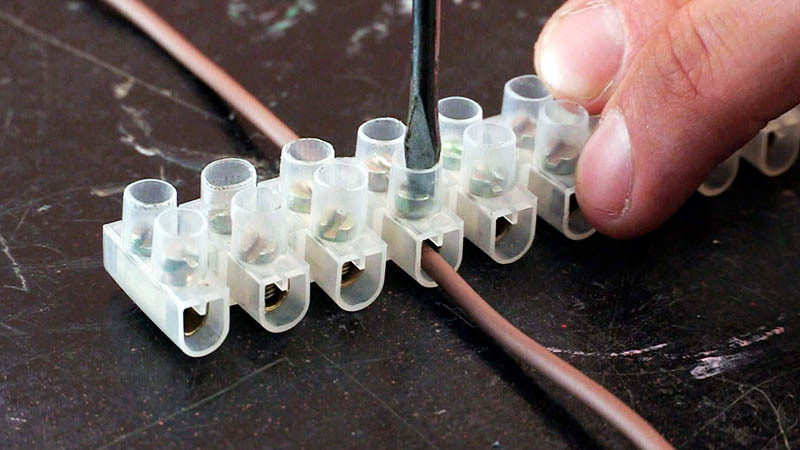

Screw pads and their use

Quite a reliable option, but such work takes a lot of time. Despite the fact that such connections have been performed since Soviet times, they still have not lost their relevance. Such pads make it possible to connect aluminum conductors with copper, which in no case should be done in the case of twisting.

WAGO: to use or not

A lot of controversy can be heard about terminal blocks WAGO. Here it is necessary to dwell in more detail. Opponents of such compounds argue that VAGO can melt. However, if you look at it, the maximum current for which the outlet is designed is 10 A. The most common machines installed on outgoing lines are designed for 16 A, sometimes for 20 A. At the same time, the most powerful thing in the apartment is washing machineconsuming 9 A.

Now - with regard to WAGO. They are designed for a current of 20-32 A. Therefore, they are completely safe for wiring in an apartment. Of course, we are not talking about connecting powerful workshop equipment somewhere in the private sector. The main thing here is to choose the right terminal block. For example, if they are empty (transparent) for copper, then a special lubricant is stuffed into them to combine aluminum to prevent oxidation. To be precise, this is a quartz-vaseline lubricant. At the same time, it is not terrible for copper, which allows using WAGO to connect these metals without consequences.

Such terminal blocks can differ in series, which is now discussed.

Related article:

Terminals for connecting wires: advantages and disadvantages, requirements, criteria for the correct choice, types of terminal blocks, an overview of manufacturers, stages of connecting wires - in our publication.

WAGO series for faster installation and easier repairs

WAGO terminal blocks can be either self-clamping or spring-loaded. They differ in series, which will be considered in tabular form for the convenience of information perception.

| Illustration | Series | Peculiarities |

| 773-30x | Self-clamping terminal blocks considered disposable. To connect, it is enough to stick the wire all the way, after which it is fixed automatically. Connector in gray or black opaque body, filled with quartz-vaseline grease, which removes oxide and prevents its formation. Designed for aluminum and copper rigid wires. |

| 773-32x | Just like the previous ones, they are self-tightening. The difference is in the transparent case, which allows you to control the degree of immersion of the conductor. Used for copper wires only. There is no lubricant inside. The number of connected cores is from two to eight. The rated current of the series is 20-24 A, the voltage is 0.4-0.6 V, the discharge voltage is 4 kV, the temperature is up to +85 ° C. |

| 222 | Lever spring clip, reusable. Allows clamping of flexible copper wire. The 10 mm stripped part of the core is inserted into the socket with the foot raised, after which it is lowered, the wire is clamped. Rated current 32 A. |

| 221 | Similar to the previous version, but more compact. |

| 224 | This model of the series makes it possible to butt-connect the cores. |

These are the main series, which have their own varieties, differing slightly.

A few words about safety during electrical installation

Electric shock is extremely dangerous to health - up to and including death. Therefore, compliance with safety precautions is necessary here. And the basic vital rule is to work in junction boxes only when the voltage is removed (disconnected input circuit breaker).

It is also necessary to pay attention to the insulation of the handles of the working tool. After all, even if the tension is removed, one should not forget that we live in Russia. There will always be a person who wants to "help his neighbor" by raising the machine's flag up.

Finally

Accuracy in electrical installations is only part of the process. You also need to think for the future, because no one is immune from breakdowns, wire burnout. Therefore, it is necessary to provide for the possibility of subsequent repair of the home electrical network. But nevertheless, the main thing in such work is attentiveness and accuracy.

We hope that today's article will be useful to our dear reader. Homius editors will be happy to answer your questions, which can be left in the comments below. There you can also discuss the pros and cons of the presented compounds and indicate what, in your opinion, is wrong in the information presented. And also - do not forget about the rating, your opinion is extremely important to us. And finally, we offer for viewing a video on today's topic, which will definitely be of interest to you. Take care of yourself, loved ones and be healthy!