Increasingly when laying electrical wiring corrugated pipes made of PVC, HDPE (low pressure polyethylene) or metal began to be used as a cable channel. This is very convenient because it allows you to easily replace burnt or broken wires without destroying the wall surface and finishing, which cannot be said about tightly walled cables. However, this case also has its own difficulties. In today's HouseChief review, we'll look at ways to get wires through a corrugated hose without factory pulling.

Read in the article

- 1 What is a corrugated conduit for electrical wiring

- 2 Material for manufacture and scope

- 3 Couplings - the easiest option

- 4 With the help of a factory "conductor"

- 5 Vacuum cleaner

- 6 Magnet and nut

- 7 A few words in conclusion

What is a corrugated conduit for electrical wiring

The corrugated pipe is a flexible ribbed hose made of various materials for hidden or surface mounting of electrical wiring. It perfectly withstands temperature extremes, moisture and allows you to preserve the integrity of the wires from various external influences. The corrugated hose makes it possible to lay electrical wiring of any complexity and length with a minimum number of joints and turns.

Important! Laying wiring in corrugated pipes is a requirement of SNiP. Building codes determine the outer and inner diameter of the corrugated hose, wall thickness, height and width of corrugated ribs. Rates may vary depending on the material used to manufacture the pipe.

Material for manufacture and scope

In the manufacture of corrugated pipes for the installation of electrical wiring, a variety of materials are used:

- Polyvinyl chloride (PVC) - the material is lightweight and self-extinguishing. These hoses are usually available in gray and are used in dry rooms because they are sensitive to direct UV rays and not resistant to moisture.

- Polypropylene (PPR). Corrugation made of this material is resistant to combustion, direct sunlight and moisture. Polypropylene hoses are used for installation of electrical wiring outdoors and in rooms with high humidity. As a rule, the color of such pipes is blue.

- Low pressure polyethylene (HDPE). The material has a high level of moisture resistance, so such hoses are used for wiring from the outside of buildings and in rooms with high levels of humidity. HDPE is flammable, making it unsuitable for use in wooden structures. It is allowed to use such corrugated hoses in screeds and in structures made of non-combustible materials. Available in black or orange.

- High pressure polyethylene (LDPE). The material is flammable, therefore it must be mounted inside structures that do not allow fire (foam block, reinforced concrete products, etc.).

- Polyamide (PA). It is a rather flexible material that is highly resistant to mechanical and physical stress. Polyamide corrugated hoses can be used in a wide temperature range of + 60... + 150 ° C, they are laid outside and inside buildings, and are also fire-resistant. Polyamide corrugated pipes are available in dark gray color.

- Metal corrugation. Mainly manufactured from durable and corrosion resistant stainless steel. This metal perfectly tolerates aggressive environments and protects the cable from various mechanical influences. Metal corrugated hoses are used for indoor and outdoor installation of electrical wiring, as well as inside structures made of combustible and non-combustible materials, on the street when laying underground and air communications.

Couplings - the easiest option

This method is the easiest, but not everyone may like it. It is suitable for those who do not want to bother pulling a cable through a long corrugated pipe or when repairing a damaged area. The bottom line is that the cable is pulled through relatively short pieces of corrugated pipe and special couplings. The joints are sealed.

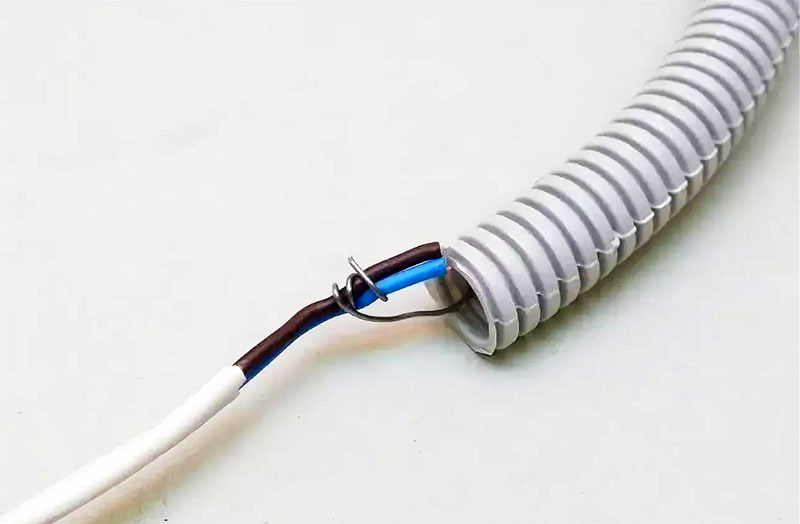

With the help of a factory "conductor"

Most manufacturers of corrugated hoses for electrical wiring integrate a steel wire (conductor) into the product. A cable is firmly attached to one of its ends, and then the other end is pulled until the cable is completely pulled into the corrugated pipe. This is the easiest way, but it also has its own nuances. Firstly, an assistant is required to pull the wire in a corrugated hose, especially a long one, and secondly, the flexible pipe must be fixed so that it does not move with the cable.

Vacuum cleaner

A rather interesting and unusual way to stretch a cable in a corrugated pipe is to use a vacuum cleaner. To do this, you need a piece of foam rubber or a paper ball, fishing line and the vacuum cleaner itself. We take a ball of paper or foam rubber and tie a strong fishing line or twine to it that exceeds the length of a corrugated hose. We insert this peculiar "wad" into one end of the pipe, and apply the vacuum cleaner hose to the second (it is better to use a nozzle for hard-to-reach places). We turn on the vacuum cleaner and wait until it tightens the ball with fishing line or twine, to which we tie the cable. We wrap the junction for better sliding with electrical tape.

More details about pulling a cable in a corrugation using a vacuum cleaner can be found in this video:

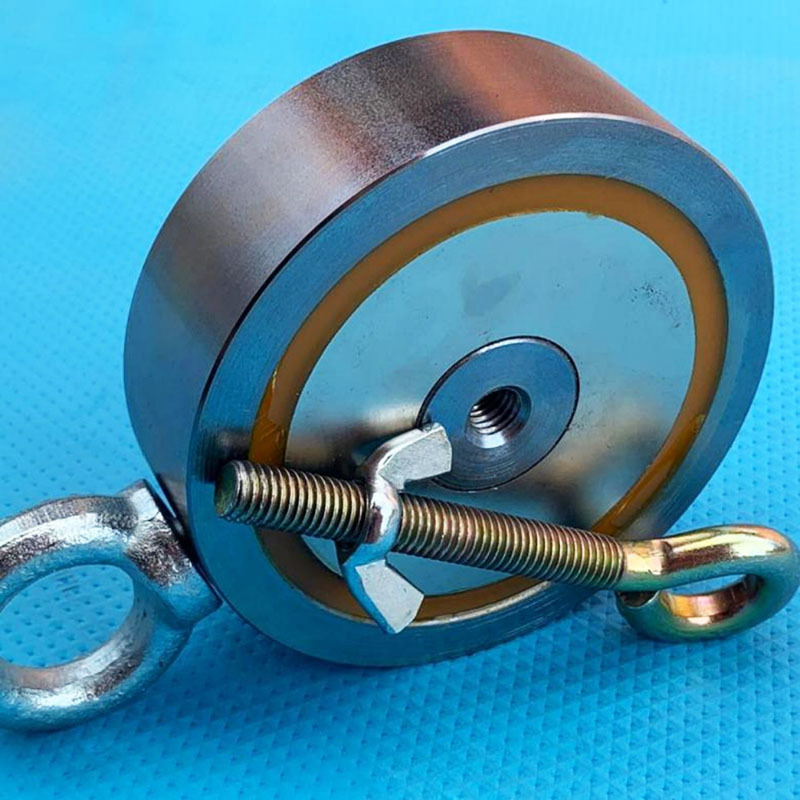

Magnet and nut

Another interesting and effective way to tighten the cable into the corrugated hose is to use a nut, fishing line or twine and a powerful magnet made of rare earth metals. Tie a fishing line or twine to a nut, washer or bolt and insert it into the corrugated pipe. Outside the hose, place a neodymium magnet against the wall and hear the metal object literally "stick" to it. Run the magnet along the entire corrugated tube until a nut or bolt with line appears on the opposite end. Tie a wire to one end of the homemade broach and gently pull it out. A second magnet can be used instead of a nut or bolt.

A few words in conclusion

Corrugated pipe is a good option to carry out an aesthetic and high-quality installation of wires, which, moreover, meets the requirements of SNiP. Whether or not to use a corrugated pipe is up to you. We hope that the information provided by us was useful to you, and you will share it with your friends.