Few know how to properly dock linoleum together; this experience comes after repeated attempts, not always successful. If you are looking for a floor covering that is relatively inexpensive, durable and easy to maintain, and can also be installed without assistance, then linoleum is the best choice. The main thing is to lay it down without mistakes in repair, which are typical for many beginners. They are most often noticeable precisely at the joints. It is especially difficult to cope with the task if the junction is in a noticeable area, because it is important that it is not at all conspicuous. How to solve this problem - in a small review from HouseChief.

Read in the article

- 1 How the junction depends on the quality of linoleum

- 2 How the junction depends on the pattern of linoleum

- 3 How to connect correctly: butt or overlap

- 4 Linoleum joining options

- 4.1 How to properly join linoleum with each other by cold welding

- 4.1.1 Algorithm for using cold welding

- 4.2 Features of hot welding of linoleum

- 4.2.1 How does hot welding work?

- 4.3 Joining canvases with tape and sills

- 4.1 How to properly join linoleum with each other by cold welding

How the junction depends on the quality of linoleum

There are quite a few types of this flooring, but they all fall into two main categories. It is a material for domestic and commercial use. Household appliances usually have a smaller thickness and are not as resistant to external influences as commercial ones, this is not surprising: after all, the load at home is not the same as, for example, in an office.

Nevertheless, if you can afford to purchase commercial linoleum, then stop the choice on it. Despite the expense, you will receive significant savings over time, because it will last at least twice as long. And give up the idea of laying material less than 3 mm thick, it will fail in a year or two.

Note! This floor covering only appears to be monolithic in appearance. In fact, it consists of three layers: the outer one, consisting of PVC, an interlayer of fiberglass mesh and a foam backing.

When joining materials, it is important to take into account all these characteristics, and it is especially important to take them into account if you need to combine two types of linoleum.

How the junction depends on the pattern of linoleum

PVC flooring has a varied assortment and colors. It can imitate natural wood or stone, look like parquet or leather, and have a bright pattern. It is important to take into account the peculiarities of the colors when joining the canvases.

In this case, be sure to take into account the necessary allowance for such a fit when purchasing. This will be additional costs, but without connecting all the lines of the drawing, the joint will immediately catch the eye, violating the whole harmony of your interior.

How to connect correctly: butt or overlap

There is a great temptation to overlap the panels. It is simple, it is difficult to make a mistake in a seam and, at first glance, more reliable. But do not delude yourself: the overlap is vulnerable to moisture penetration, in addition, it forms a noticeable unevenness on the floor that you can trip over. Those who argue for such a choice by the possible shrinkage of the material, most likely, do not know that modern high-quality coatings do not give such shrinkage.

Linoleum joining options

What should be the ideal linoleum joint? It should be neat, inconspicuous, durable and airtight. Only in this case you will get a solid canvas that will not let moisture and dirt through.

There are 4 options to achieve this result:

- using double-sided special tape;

- cold welding using glue;

- sills or partitions;

- hot welding on a special cord.

All these options give a good quality result, but there are some nuances in the application of these methods that you need to know about.

How to properly join linoleum with each other by cold welding

For this type of connection, you need to purchase a special glue for linoleum. How does it differ from conventional formulations? The fact is that such compositions do not just glue the edges of the material, they dissolve them a little, which makes it possible to connect at the molecular level.

Cold welds for PVC are highly toxic, so you need to work with them extremely carefully, using personal protective equipment, in a ventilated area.

Types of cold welding and their features:

- Type A - suitable for new canvases without additional insulation layer of felt structure. It is used at joints of short length, rather liquid, dries in 30-40 minutes.

- Type C - joins the canvases in the presence of a gap, suitable for repair work, thick, well joins thin canvases.

- Type T - for coatings with a polyester base, it is considered universal, as it is suitable for working with new materials and for repairs. The most expensive type of glue, used primarily on commercial linoleum.

A comment

Mikhail Starostin

Head of the team of the repair and construction company "Dom Premium"

“All types of cold welding are very durable joints, and if the composition gets on the front part of the coating, it is quite difficult to remove it. You have to wait until the drop has completely solidified and then remove it with a knife. "

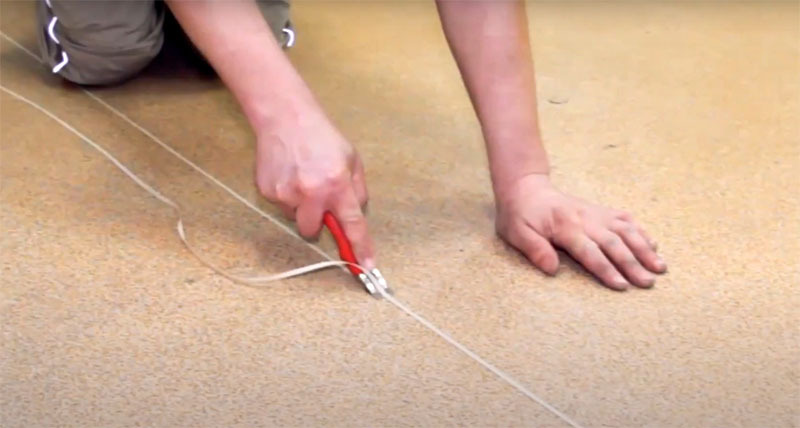

Algorithm for using cold welding

Features of hot welding of linoleum

If you want to get a guaranteed strong joint that will withstand an increased load, then the best option is hot welding of linoleum. It is extremely rarely used for floor decoration in private houses and apartments. Basically, this type of connection is used when joining a commercial coating.

Hot welding requires several special tools, so it is impossible to repeat this experience on your own at home. Even if you purchase equipment, there is a high probability of spoiling the material, since only professionals can choose the right temperature so as not to melt the canvas and not get dross on the seam. The device heats up to +450 ° C, which is a very high temperature that can ruin your flooring if the equipment is used incorrectly.

How does hot welding work?

Joining canvases with tape and sills

The simplest linoleum connector is considered to be double-sided tape. He glues the material to the floor and holds the canvases together. This can be done quickly and inexpensively, but this method is not considered reliable, because with it the canvases do not join together, but only stick to the floor.

Paths are more appropriate when joining linoleum with other materials, such as floor tiles. This method of joining will hide the difference in height and protect the junction from moisture and debris. If there is a need to dock a place at an angle, use a special profile.

The question of an even joint is not only when laying a new canvas, but also when repairing an old one, gluing pieces. Here is a small but very useful video on this topic:

If you still have questions on the topic, write in the comments. And share your opinion on which of the methods seems to you the most effective.