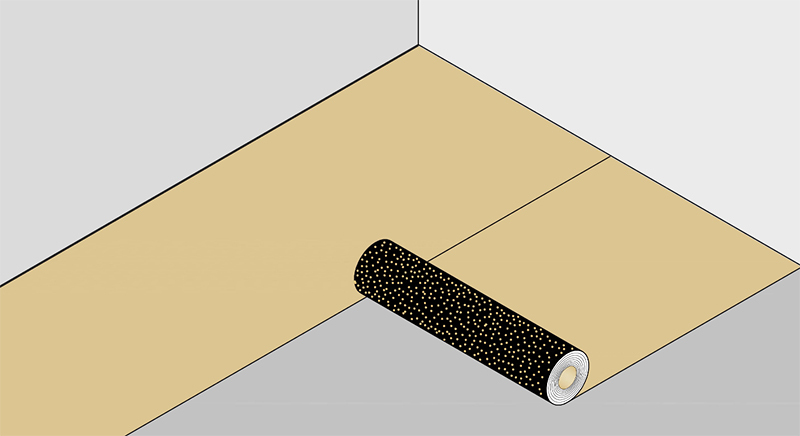

To flooring it turned out smooth and of high quality, it is necessary to lay it correctly. All stages deserve attention. We propose to figure out which linoleum substrate is better and why. This will help you find the best option for your home.

Read in the article

- 1 Functions of the linoleum substrate

- 2 Performance characteristics, advantages and disadvantages of substrates by type

- 2.1 Jute and cork

- 2.2 Coniferous, linseed and felt

- 2.3 Polypropylene and foil

- 2.4 Combined

- 3 Is a substrate always needed for linoleum: we take into account the situation

- 3.1 When a backing is needed: possible situations

- 3.2 When to Neglect: The Essential Checklist

- 4 Which substrate for linoleum is better: when choosing, we take into account the goals pursued

- 4.1 For cold floor insulation

- 4.2 For soundproofing

- 4.3 For leveling the base

- 5 Leading manufacturers

- 6 Popular varieties depending on the financial ability of consumers

- 6.1 Budget price segment

- 6.2 Medium and high price category

Functions of the linoleum substrate

The linoleum substrate performs several functions at once. This layer:

- enhances sound insulation level decorative coating;

- increases thermal insulation characteristics, which is especially important for the first floors;

- levels the base. The underlay allows you to smooth out existing irregularities and defects in the base;

- creates an optimal indoor microclimate, regardless of its purpose;

- prevents the appearance of mold and mildew on the surface of linoleum.

Performance characteristics, advantages and disadvantages of substrates by type

The performance characteristics of the substrate are directly dependent on the material used in the production. Manufacturers offer a fairly large assortment. Each type has its own advantages and disadvantages. We invite you to get to know them.

Jute and cork

For the production of jute backing, a coarse textile fabric made from plant fibers is used. For the production of the latter, annual spinning plants are used.

The advantages of such a substrate include:

- environmental friendliness;

- high rigidity and elasticity;

- good heat and sound insulation characteristics;

- resistance to fire, biological resistance due to processing with special compounds;

- ease of styling;

- the ability to mask the subfloor;

- durability.

The main disadvantage of jute linoleum backing is its high cost.

For the manufacture of a cork substrate, it is worth attributing crushed bark. Stopper is an intermediate derivative wood, which contains lignin and wax. Thanks to this, the material turns out to be solid and resists moisture well. It also has sufficient elasticity. The advantages of a cork backing for linoleum include:

- high heat and sound insulating characteristics;

- hypoallergenic;

- the ability to align the base well;

- good resistance to mold, rot and mildew.

Among the shortcomings, it is worth noting:

- softness of the material;

- restriction on use in high humidity conditions;

- deformation under the weight of heavy objects;

- increased requirements for installation work;

- high cost.

Coniferous, linseed and felt

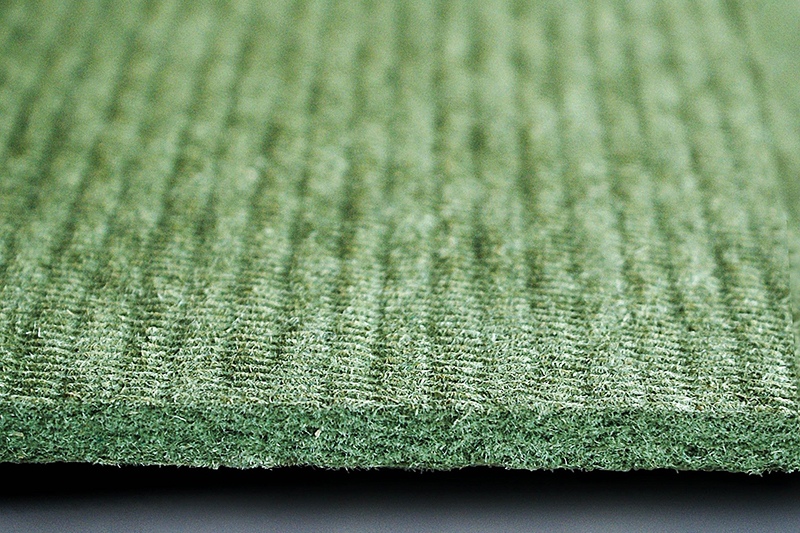

Needle linoleum underlay is a relatively new insulating material. For its manufacture, the remains from the processing of coniferous wood are used. The material has high sound insulation characteristics and retains heat well.

Attention! Initially, the coniferous linoleum substrate has a specific smell, but over time it disappears.

The linen backing provides good air exchange between the decorative coating and the concrete base. This prevents the growth of mold and mildew. Such material attracts with environmental friendliness and resists fire well, since it is treated with special impregnation during the production process. Demonstrates good heat and sound insulating properties. Among the shortcomings, it is worth noting poor resistance to deformation with medium strength and stiffness.

Felt backing for linoleum is made of wool by felting. After processing the raw material with steam, it is combined into a single piece. Additionally, the material is treated with special substances that protect the felt from decay and fire. Natural material is environmentally friendly, elastic, soft, abrasion resistant. It conducts well and retains heat.

Polypropylene and foil

A polypropylene foam backing for linoleum is an affordable option. The duration of operation of such a layer depends on the conditions. On average, it is 5-10 years. The advantages include ease of installation and repair. The disadvantages include excessive softness due to the small thickness of the material.

Foam-based material consists of isolone. Aluminum foil is used as a heat reflector. Often used for installation underfloor heating systems. Possesses high strength and moisture resistance.

Combined

Several different materials are used simultaneously to make such a substrate. Manufacturers offer a coating consisting of flax and jute, flax, jute and felt, cork chips and bitumen. The latter is used as a binder.

Among the shortcomings, it is worth noting the lack of moisture resistant properties, low ventilation capacity due to high density. Among the advantages, it should be noted high wear resistance, naturalness, good resistance to deformation with high noise insulation characteristics.

Related article:

Linoleum for laminate: photo in the interior, existing varieties, size and color schemes, recommendations for choosing a suitable option, reviews of real buyers.

Is a substrate always needed for linoleum: we take into account the situation

When choosing a substrate for linoleum, it is imperative to take into account the conditions for the future operation of the floor covering. In some situations, you can safely refuse an additional layer. To do this, you need to decide when the substrate is needed, and when the installation can be done without it.

When a backing is needed: possible situations

Despite additional financial investments, it is imperative to purchase a substrate if in the house:

- cold floor. A well-chosen substrate will increase the level of thermal insulation of the floor surface, becoming a protective barrier against the cold. Relevant for private houses and apartments located on the ground floor. At the same time, preference should be given to the material on a natural basis;

- uneven floor. When making a screed with your own hands, it is quite difficult to form an even base. Substrate eliminates existing problems, for example, on a wooden floor;

- it is planned to lay single-layer linoleum. Having decided to save on decorative coating, it is worth taking care in advance of ensuring a sufficient level of thermal insulation by laying an additional layer.

When to Neglect: The Essential Checklist

In some cases, you can save money and refuse to buy a substrate. Linoleum can be laid immediately if:

- it is laid on the old floor. You can do this if the base is initially flat and free of flaws. If there are defects, the old floor covering must be dismantled;

- a multilayer material with a jute or foam base, comparable in its characteristics with a standard base, was selected. This greatly simplifies the installation work.

Related article:

Linoleum adhesive: how to choose a brand, the main types of adhesives and their features, leading manufacturers, popular brands, features of gluing linoleum on various substrates.

Which substrate for linoleum is better: when choosing, we take into account the goals pursued

In order for the substrate to cope well with the task assigned to it, the purpose of the purchase should be taken into account when choosing the appropriate option. This will allow you to select the best option for specific operating conditions.

For cold floor insulation

Quite often, the substrate is used to increase the thermal insulation of the floor covering. Thanks to its presence, it is possible to reduce the outflow of heat from the room. For this purpose, it is best to use a combined material consisting of linen, wool and jute. This floor is much more comfortable to walk on.

For soundproofing

To ensure a sufficient level of sound insulation, you need to pay attention to the structure of the material and its thickness. Most often, preference is given to fibrous substrates and products made of cork. It is permissible to use a layer of foamed polymer.

For leveling the base

If the base cannot boast of perfect evenness, the linoleum underlay will help align it. For this, it is worth choosing a material with a high density. Combined polymer coatings, as well as products made from pine needles, have proven themselves well.

Related article:

Laying linoleum indoors: general requirements and rules, what preliminary work needs to be done, how correctly to remove the size of the room, the criteria for choosing a coating, the main work on laying linoleum - in our publications.

Leading manufacturers

When choosing a suitable option, you should pay attention to the products of leading manufacturers. The leading positions are traditionally occupied by products:

- Technotex. A well-known Russian company offers a wide range of products. You can always choose the appropriate option in terms of density, thickness and cost. There are jute, linen and combined materials;

- Vintage Floor. The company from Portugal offers high-quality and expensive ecological products. Small thickness (up to 3 mm) makes it possible to use it when preparing a flat base without defects;

- Steico. German products are made from natural raw materials. Differs in high cost;

- Petroform. Long-lasting artificial material.

Popular varieties depending on the financial ability of consumers

The cost of a linoleum backing can vary significantly. When choosing a suitable option, you should definitely take into account your financial capabilities. Before giving preference to a certain variety, it is worth considering which of them are in high demand among consumers.

Budget price segment

The budget options include a foam backing. The cost of such material depends on its thickness. The price of one square starts from 20 rubles with a thickness of 2 - 3 mm.

Medium and high price category

Other products belong to the middle and high price category. A square of a coniferous layer with a thickness of 3 mm will cost at least 80 rubles. The cost of cork starts from 125 rubles per 1 m². The thicker the material, the higher the selling price will be.

Share in the comments which substrate you have decided to give preference to and why.