You want to know the truth about the insulation? Set fire to it. It is no accident our interview with Sergei Olnitskim, commercial director of direction "Polymeric membranes and PIR» Corporation TECHNONICOL started with clear attempt to ignite the gas burner PIR-plate. The material that came to us from outer space *, stoically blackened, slightly charred on the side, but did not give any chance to go on fire.

- Sergey, in the description, we do not accidentally put the word cosmos star. How did the idea to introduce in the construction industry insulation PIRDesigned for space exploration and military purposes?

- Military and aerospace engineers, designers and chemists have to constantly look for new ideas to solve very specific problems. For example, how to ensure maximum insulation space station or fuel tank missiles with a minimum thickness of the insulation? And there is nothing surprising in the fact that the authors of these decisions create innovations that will shape the future of dozens of related industries "civil" economy. After all, in the construction and life of the people are facing similar problems with space. The most glaring example - cool balcony! It should insulate as much of the already small space - as the compartment on the space station.

Such scope is due to the properties of PIR, which withstands extreme temperatures of outer space, where temperature gradients ranging from + 120 ° C to minus 150 ° C. Therefore, the insulation on the basis of PIR was the uncontested technology to protect the fuel tanks of launch vehicles, including the space shuttle "Buran". After PIR thickness of only 1.6 centimeters able to isolate not worse than the wall thickness of the concrete of 1.34 meters. In military and industrial complex USSR PIR used as passive protection from exposure to incendiary projectiles.

With the collapse of the Soviet Union's production technology PIR was forgotten: the production line went to the scrap specialists fled to other industries.

TECHNONICOL company aims not only to improve the existing building materials, but also to develop new solutions. It is no accident today in the company of several asset own research center, designed to change the image of the construction industry through the development and implementation of effective and useful innovation. I note, for research and development, we are laying up to 4% of the turnover of our business units. This is a very high figure even for high-tech companies in Europe, USA and Japan.

So in 2013 we decided on a new technological level to revive the case of Soviet engineers and chemists, figuratively speaking: after PIR from space on roofs and balconies of our houses, public and industrial buildings.

In 2015 it was launched a modern plant for production of PIR-plates under the trade mark LOGICPIR. This venture, which we can rightly be proud of. It is one of the largest in Europe. The design capacity of the production line - 15 million m2 per year.

The line is almost completely automated and eliminates the most "human factor". We are pleased to show our factory partners and customers, excursions to the Science Center and production do not leave anyone indifferent person.

LOGICPIR plate successfully entered the market and are gaining more and more attention to corporate and private consumers. After all, the material does not support combustion, without getting wet, no deformation, can withstand high mechanical loads, it has excellent thermal insulation characteristics and saves space. This is a handy high-tech product for insulation balconies, baths, floors, walls, roofs, attics.

In the United States, for example, 76.4% of flat roofs are insulated using PIR, greater than 40% in Europe. The share of PIR-products in the European construction is growing annually by an average of 3%.

- Tell us about the structure and the physical structure of the innovative insulation LOGICPIR.

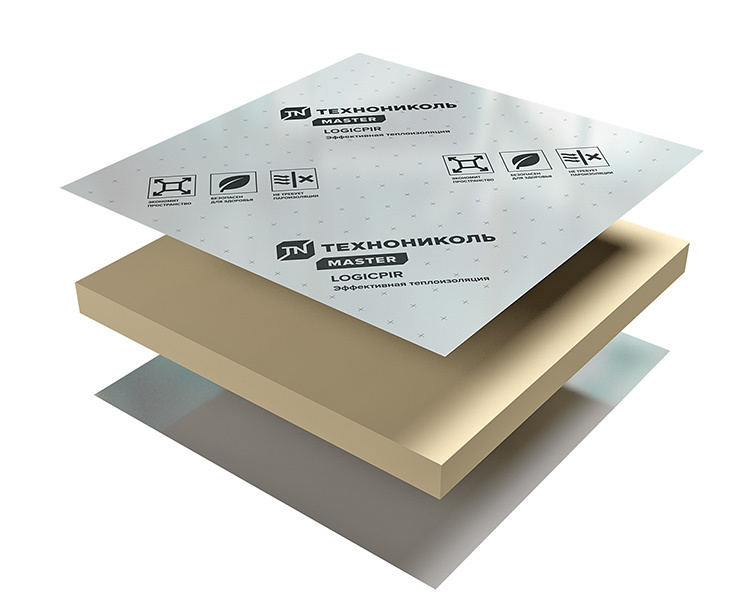

- The centuries-old practice has proved - the air contained in the porous material is an excellent thermal insulator. On the basis of this principle, the work of the foam and even ordinary straw. By LOGICPIR structure resembles a very dense and solid sponge consisting of a plurality of closed cells filled with an inert gas. Due to such a structure, the material has very low thermal conductivity - up to 0.021 W / m • K. Plus, PIR plates on both sides are lined with aluminum foil, acting as an additional reflective insulation.

- In what form is made LOGICPIR?

The optimal form for modern insulating materials - plate. We produce slabs with different dimensions in thickness, length and more - depending on the application. For example, for thermal insulation: balcony, floor, bath - requires small-size plate - 1200 on 600 mm, which can be taken away in the trunk of a personal car and is easy to install in a limited space. For the insulation of flat roofs of residential, public and industrial buildings, as well as the production of sandwich panels are manufactured with large plate size, a standard size plates 2400 to 1200 mm.

- Current issue - sustainability mother. In the media there are publications about the dangers and toxicity PIR materials, emission of toxic gases when heating the material?

- Share LOGICPIR heaters on the market is growing every year, so we have seen in the media incorrect "Stuffing", which refer to material toxicity and harm to human health, until the development of Oncology.

In fact, the major component LOGICPIR insulation - polyisocyanurate (modified polyurethane). This material, which is commonly used in interior decoration of vehicles, it is used in the manufacture of footwear, furniture, mattresses, children's toys. All these things have a national and international safety certificates to human health. All modern orthopedic pillows make it from polyurethane. Moreover, manufacturers write about it in big letters on the label, so as polyurethane - safe material.

Of course, LOGICPIR TECHNONICOL also passed all stages of research and testing, including independent European certification authorities. The material was tested for emission of harmful substances, including during heating. LOGICPIR received the certificate for use in the construction of children's institutions.

- How LOGICPIR meets construction requirements in terms of durability and biopersistence, resistance to fire?

- Closed cell polyurethane foil surface and impart high strength plates PIR - more 150kPa, while maintaining the strength and geometric characteristics of more than 50 years, even with active dynamic loads. For example, on the roofs of commercial and industrial facilities, as a rule, we found a huge amount of equipment that requires regular maintenance, and hence the frequent movement of the roof. We have calculated the limit values of the loads, and it turned out that on the roofing system LOGICPIR plates can walk the... adult African elephant! Its average weight - 7 tons. The main thing that the supporting structures of the roof did not disappoint.

With regard to the biological stability LOGICPIR, these indicators also have all the supporting opinions and certificates. On the surface LOGICPIR not develop microorganisms: mold, fungi, etc. It is crucial in designs saunas, breeding complexes.

One of the most important indicators - to the stability of the flame. PIR refers to the self-extinguishing materials. In practice this means that when subjected to fire, the top plate layer is carbonized, and attenuated without supporting combustion and preventing the fire to spread.

However, the concept of "do not lit" and "self-extinguishing" - two different things. In fact, even the steel melts at a certain temperature.

Thus, LOGICPIR exposed to fire can char and deform but will not allow the fire to spread, will increase the time for evacuation.

- What is the stated service life, during which guaranteed the preservation of the insulating properties of the material LOGICPIR?

- We produce material in 2015. But tests in the laboratory, where the simulated harsh operating conditions, seasonal changes in temperature, cycles freeze / thaw, we demonstrated that LOGICPIR almost 100% retains all its properties throughout 50 years. World experience in practice confirms this figure - in 2018 was exactly 50 years since the beginning of operation PIR materials.

- No special skills and tools for installation LOGICPIR not required. Moreover, our company has been a fun event. Our fellow marketer - Elena Lementueva not believe that LOGICPIR can be installed independently. It is suitable for technicians with a question: "Are you saying that I myself will be able to insulate a balcony?". All answered it in the affirmative. As a result, we decided to conduct an experiment: made crate (after all repairs are not a woman's business), and she mounted the insulation yourself.

LOGICPIR is extremely simple to install and does not require any radical physical effort. Weight of one plate only 500 grams. I am sure that any girl beautician will obviously heavier than one plate LOGICPIR. Therefore, for the energetic and curious girl from the friendly team TECHNONICOL this was an easy task. Needless to say that the balcony was well insulated? Plates are L-edge, to prevent so-called "cold joints". The junction plates glued aluminized tape.

- What is the scope of application LOGICPIR? In what area it is more effective on large construction sites or repaired, or in the private sector - to insulate houses, balconies, etc.?

- Scope of our material has no restrictions - it can be commercial and industrial buildings, private houses, apartments. As I said before, for each area produced slabs relevant dimensions.

- What are your recommendations for the owners of apartments and private homes - where it is better to use the heater, where it is possible to buy and what to look for when buying?

- We work with many trading partners, as well as shops format DIY. PIR is already represented in many regions in small stores and construction markets.

When you buy should pay attention to the thickness of the material. For the segment of private construction and repair we offer plates of thickness 30 mm and 50 mm. The final thickness should be selected based on the characteristics of the object of insulation.

LOGICPIR on the site you can get acquainted with the recommendations, the installation instructions for all possible designs. Ibid placed hotline number, where you can get answers to all their questions.