Advances in technology now and then leads to the appearance of new materials. A real revolution for the man called polyurethane, the appearance of which has opened the doors to a number of additional industries.

What is polyurethane

Polyurethane is a synthetic material, which may have different characteristics. You can create a flexible structure, which will be stretched like rubber or hard plastic. Widely used foam, which is widely used as a sealant or insulation.

Various structures are obtained owing to mixing of different components. Possible variations there are infinitely many. It was first produced in 1937 in Germany. Then production has spread all over the world. It is now used in numerous industries.

He has a number of competitors who are in some way superior, and in some ways inferior to the polyurethane.

properties of polyurethane

Properties depend on the specific structure and composition. But all polymers combines high elasticity option. The polymer is capable of changing its size under the influence of the load, and then return to starting position. Moreover, the resource parts is high. It is possible to apply a force of up to 50 MPa, despite the fact that the final strain will be minimal.

Important! The polymer is quite durable and has a low sensitivity to temperature. It hardly changes its properties and performance at a temperature of from -60 to +80 degrees.

Features:

- In polyurethane high hardness.

- Wear resistance.

- Elasticity even under high hardness.

- Resistance to mold, mildew and the appearance of different microorganisms breaking structure.

Specifications

Technical characteristics of the polyurethanes may vary, but they share a few options:

- The mechanical strength of various polyurethane.

- Resistance to abrasion.

- Elasticity.

- A wide range of operating temperatures.

- Dielectric properties.

- Low thermal conductivity.

- Oil resistance.

- Chemical resistance to solvents.

- Water resistance.

In general, the polymer is reliable. But it is worth noting that the operation of parts of the polyurethane at low temperatures can lead to increased brittleness and loss of useful properties.

Advantages and disadvantages

Like other materials, polyurethane has advantages and disadvantages that make it different from its analogues. Benefits include:

- Longevity and slow aging.

- Can withstand heavy loads.

- Well recovers its shape after mechanical deformation.

- Elasticity.

- Virtually no stick pollution.

- Much less weight compared to metal parts.

- It does not conduct electricity.

- Resistant to a variety of abrasives.

Polyurethane is much cheaper than other materials, which can significantly reduce the production costs of parts. Mechanisms of polyurethane operate almost silently, as the details are not strongly rub against each other and do not cause rattle.

Compared to metal, it requires much less maintenance. It provided improved resistance to impact, and elasticity of a solid surface on which it is difficult to leave scratches. Exposure to temperatures does not affect the properties, because the working range is pretty wide. We should also highlight the low weight, which seems an important factor in a variety of machinery and parts.

It is possible to create a material with any desired properties. Advantageously, it refers to the coefficient of friction for the polyurethane. It can be anything.

Important! Polyurethane during use can change its dimensions up to 600%, and then return to the initial position. None of the other common material does not possess these properties.

But it was not without flaws. By cons polyurethane include:

- Difficulties recycling.

- At low temperatures the material becomes brittle and breaks down quickly under load. Flexibility is practically zero.

- Poor resistance to twisting.

- Foamed material shrinks, which can lead to disruption of indistinct outline and shape.

- The lack of breathability makes little use material for the manufacture of some parts.

Sometimes the question arises whether a person is bad for polyurethane. To answer it, we must know the composition of the particular material. And since they are different, then no one will give a precise answer. Some of the components may actually be harmful to health, but most of all in the normal range.

types of polyurethane

There are many types of material, each of which has its own characteristics. But in almost all countries the most important are the three main types of industrial polyurethane.

Adipreny

Material, characterized in high levels of elasticity and excellent shape retention. Adipreny widely used to create the tires, gaskets, various coatings. The main purpose of the materials is considered the protection of other parts of constructions from deterioration caused by excessive, repetitive load.

Vulkollan

A separate group of materials which are capable of operating at temperatures up to 120 degrees. This figure allows the details in a large number of industries, mainly related to the creation of bearings or bushings.

Vulkopreny

Type, which is rarely used in its pure form. Vulkopreny usually used in conjunction with other polymers in order to give them the necessary strength properties.

Areas of use

Due to their properties of the polymer has been applied in a number of industries. Materials different structures perform fundamentally different and sometimes even contradictory objectives:

- Liquid polymers typically accomplished by treating building structures, bodies and more. This allows you to achieve greater resistance to impacts.

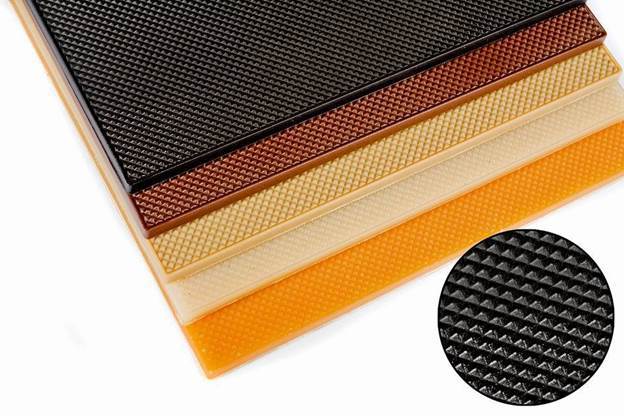

- In a foam material is often used for insulating various surfaces. Of sheet metal made support for the wheels, seals, tiles, skirting boards, and more.

- The properties of the material allow its use as linings in various technical constructions. This approach saves the item of premature failure and ensures stable operation over a long period.

- Widely used in the manufacture of shoes, making of it the sole and skin substitutes. However, lack of breathability makes these shoes comfortable is not for everyone.

- The material allows you to create a model-designed implants for medicine, which, coupled with the mechanical characteristics of the polymer makes a fairly common material for dentures.

- In engineering you can meet a large number of parts from such polymers.

Production

Parts of polyurethane are a variety of ways, such as casting, molding, extrusion, casting, and more. The most common cast, which does not require the use of a large number of additional expensive tools. In this case it can be used a simple form, simply repeats the images necessary details.

the market now you can see the material in different forms, from liquid to solid finished parts. It is necessary to allocate separately sprayed polyurethane which can be applied in a thin layer on a different surface.

Production volumes are increasing every year. And the details of the demand of this material is not reduced. It's cheap, functional, and durable. And for most of the details of this are more than enough.

molding

Most widely cast parts made of polyurethane. In this case, to create a part, the material in liquid form is poured in a molten form. Is then subjected to cooling. And in this production may be terminated. Sometimes it takes even the final processing in the form of deburring and extra layers. However, for many parts it does not matter.

So you can create even parts with complex geometry. You need to find form. production processes are easily automated, which makes it possible to create parts in large quantities, much more affordable for the process. To speed up the production of high pressure can be applied. Here the process is similar to the production of parts made of conventional plastics.

Spread obtained and applying a surface layer of the polymer on the metal item. This approach makes the item is protected from impacts. Application can be done manually or with the help of machines.

polyurethane cost

In the market there are many different types of polyurethanes and from different companies. Prices can differ dramatically. The cost depends on the company, the type, form, and a number of additional parameters. Consider the price of the most common types of rental:

- Sheet 500x500 mm with a thickness of 5 mm would cost about 1000 rubles. At wholesale purchase price may be reduced by about half. Plates with thicknesses of 10, 20, 80 mm will cost 1600, 2400, 6000 rubles respectively.

- The rods are 20 mm to 80 rubles. 35 mm will cost 300 rubles apiece. 50 mm - 400 rubles. Starting with 100 mm prices are rising sharply. 100 mm have to pay 1600 rubles and 200 mm narrower from 9500 rubles.

The liquid material is sold by weight. The price is in the range of 500 rubles per 1 kg. But this applies to domestic material. Import can cost two or even three times as much.