Finishing work - the last and final stage of the construction of a private residence. Housing constructed of bricks, concrete blocks, natural wood. Outside, interior wooden house fully defines the style of the building. Construction of wood very warm, eco-friendly, has a positive natural energy, and with proper design is also nice.

Content

- Features of finishing wooden house

- When can I start finishing after construction

- Stages of the internal finishing of wooden houses

- Preparatory stage: how, what you want to process tree

-

The choice of materials for walls

- gypsum plasterboard

- Molded

- Block house

- Plaster

- Painting

- Using wall panels

- Wallpaper, wallpapers

- The walls in the form of log

-

The materials used for the interior floor finishes

- Laminate

- Linoleum

- carpeting

- self-leveling floor

- Parquet board, massive

- Ceramic tile

-

Stucco

- Wood

- plasterboard structures

- plastic panels

- Stretch ceiling

- Styles wooden house

- conclusion

Features of finishing wooden house

Wooden outside a small village house, country house often drawn inside a tree. Wood is very rarely subjected to staining - the texture is pleasing in appearance, because it is usually only slightly tinted, impregnated compositions against rot.

The process of building the internal decoration of the tree should not be excessively accelerated - it will negatively affect the appearance, the durability of the whole structure. Before starting the registration it is recommended to make a detailed plan to be clear about what kind of materials, types of work are needed.

To construction kept optimum microclimate, comfortable temperature inside decorate also its environmentally friendly materials. Supposed humidity of each room is taken into account in the first place - coniferous wood is not desirable used in the bath, combination bathroom, kitchen, due to excessive discharge of resin in the case of increasing temperature.

When the finish is carried out in the old, not the freshly construction, it is cleaned of residues of previous coatings - paint and other things.

When can I start finishing after construction

Immediately after the construction of the interior trim design make it is impossible - need to wait partial shrinkage of lumber, during which their size is slightly reduced, insulation - pressed. shrinking deadlines are directly dependent on the temperature, ambient humidity, the tree, the design features of the home. Built size also matters - big houses dry longer.

The structure of the laminated veneer lumber shrinks most intense the first two or three months, and in full - more than two years. Therefore, starting from the inside finish the house is recommended for at least six months after the completion of construction. Log house, unlike bar-shaped, dries almost a year. Frame construction, SIPs panels consisting of OSB and foam layer shrinkage practically do not give, because interior decoration can be done immediately after the construction.

In homes built in the winter time, the shrinkage will be minimal. To check whether the frame to dry enough, in different places it, especially on the corners, joints, glue strips of paper if they are not torn a few weeks - the inner workings can already produce.

Stages of the internal finishing of wooden houses

According to modern technology improvement interior is done in stages:

- at the beginning made zakonopachivanie;

- after inserting exterior doors and windows;

- wall coated compositions prevent putrefaction, musty, insect damage, a fungus;

- insulated ceilings of each floor, the roof;

- trail roughing, then finishing floors, treated with the protecting means if necessary;

- spend finishing decoration of ceilings;

- mounted wiring;

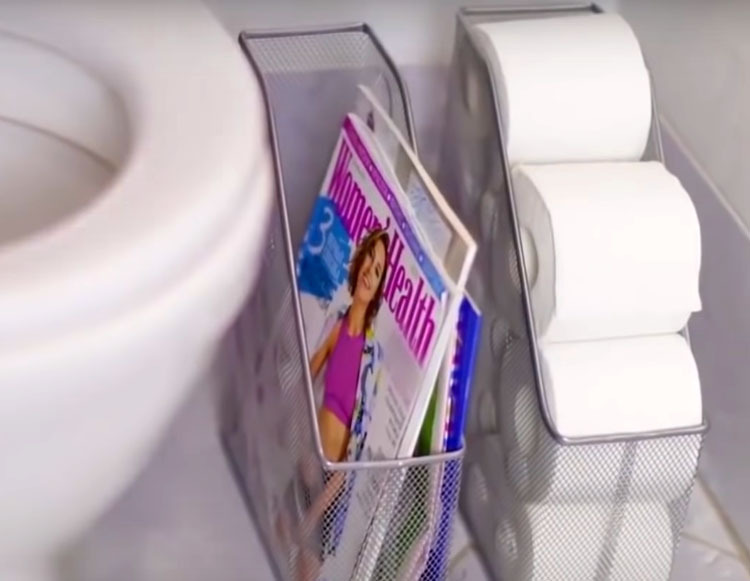

- installed, connect the heating system, sanitary devices;

- do stairs, interior doors.

The process of interior fittings at the time able to take more than the actual construction of the house, but do not hurry.

Preparatory stage: how, what you want to process tree

In the preparation stage construction requires twice prokonopatit further coating of walls made safeners. It is important to know that protection is mandatory to apply not only outside the building but inside as well. If the original timber, logs were acquired without the factory impregnation, the protection of independently created: first, all treated prior to the start of construction, and then - immediately after the construction of the house, and after a partial shrinkage - accepted comprehensive measures.

for internal processing tools should be marked accordingly, they are transparent, slightly tinted effect. What preparations are necessary:

- primer - prevent the destruction of materials, help good adhesion to subsequently applied paint;

- BIOPRO - in their composition have Antisimple and antiseptic;

- antiseptics - have the form of impregnation, coating or protecting the inside wood, forming a dense film;

- bleach - help to remove stains, often appearing in the process of shrinkage due to the emergence of the fungus. There are also useful oxalic acid, hydrogen peroxide, bleach, etc .;

- flame retardants - reduces the risk of fire, produced salt and non-salt.

Coverage begins from the bottom - processed first floors, located on the bottom, a rough floor joists, after - the space between the floors, walls and ceiling. All surfaces are carefully aligned sander, then cleaned of dust covered first antiseptic - for baths, bathroom, shower room, unheated rooms requires at least two layers. Next is antiprenom impregnation, preferably non-salt. After the primer is made, in the last instance - a decorative coating.

See also:Drawings home from the sketch to the finished project

The choice of materials for walls

Building materials for wooden house fit almost the same as for the construction of aerated concrete, brick, they are:

- Lining;

- block house;

- plasterboard, gypsum fiber board, GCR;

- interior paint;

- decorative plaster;

- wall panels of plastic;

- particleboard;

- fiberboard;

- plywood;

- wallpaper;

- wallpapers;

- ceramic tiles (for wet rooms).

If weather conditions allow the region, the walls are not made out anything further, but only impregnated with compositions that prevent spoilage. The same embodiment is permitted if a house is used only in summer.

gypsum plasterboard

Construction of plasterboard perfectly conceal large wall irregularities, as well as all communications. Of this material to construct new in-house walls, formed a niche. When used in wet rooms bathroom, toilet, recommended plate with a water-resistant coating for the kitchen, the studio - with fire resistant. Sheathing plasterboard loft material, another room having an irregular shape will look carefully original.

Drywall installation is carried out mainly in wooden crates, metal to wood structures is not recommended.

Molded

Sheathing lining is made of hardwood, softwood, at least - exotic woods. On the quality of it is divided into four types:

- Extra - panel with no visible defects, chipping, cracks, knots, dirt contrasting color;

- Class A - Good quality, slight color differences are acceptable;

- Class B - average quality, there are small chips, cracks on the front side;

- Class C - low quality, a plurality of knots, uneven coloration.

Molded mounted on lath varnished. Each other separate parts are fastened by means of studs, slots. This option is environmentally friendly, is very diverse in color, texture.

Block house

A block house represents a modified convex battens simulating part logs which cylindered. Combines elements of fastening tongue and groove, and are made as follows: whole logs cut square, what is left, well-dried, polished, becomes a block house. The material is strong, durable, has high decorativeness, but substantially vapor proof and without any special impregnation - flammable.

By processing quality of the front surface of the house unit is divided into grades Extra, A, B, C. Depending on the application is available for in-house work, simple universal, wide facade, versatile wide.

To provide sufficient sound insulation, the space between the joists insulation crates closed.

Plaster

The houses made of natural wood plaster, usually textured, get off individual zones of different rooms - a fireplace in the living room, the walls in the hallway space around doorways, windows and sills. Decorative plaster water vapor permeability, elastic, durable, not afraid of mechanical influences, manufactured all kinds of shades that allows you to choose the material for any style of an interior.

Update decorative plaster layer is recommended every four to six years.

Painting

When lumber wall quite smooth, in addition to sheathe them not necessary - you can just paint one or more different colors. Initially painted surfaces carefully grind, the seams between parts are masked by a special cord that there was no draft.

In protrudes latex paint, colored antiseptic compositions as a dye which:

- beautifully emphasize the natural wood patterns;

- Protects against the appearance of mold, mildew, rot;

- prevent the natural darkening of lumber.

Coating is performed a matte or gloss, hue and saturation depends on the number of coats applied.

Using wall panels

Wall panels are reliable, practical, beautiful look. They are available in different price categories: the most expensive are made of solid wood, cheaper - from a variety of waste. Surface finished with veneer, lacquered wood, laminated. The shape of the wall material is:

- dial-up - it has a square shape, with a side of 300 mm or 980 mm;

- sheet - 5 by 1220 to 2440 mm;

- rack - 10-12 to 120-300 in the 2400-3700 mm.

There is a classification of the basic material:

- tselnoderevyannaya cladding consisting of fine wood plus pine;

- Fiberboard - produced from wood fibers;

- DSP - is made from sawdust, shavings;

- MDF - made of highly compressed fine shavings.

The panels can also be made of plastic, with plausible imitation wood, bamboo, leather, stone, and others. Most wall panels perfectly retain heat inside the building, protected from the noise, which is particularly important in equipping children's rooms, bedrooms.

Wallpaper, wallpapers

Simple paper wallpaper - the most budget option for interior trim, but if not smooth walls, It required a special substrate, such as plasterboard, careful primer surface by gluing. Fabric options are made of wool, silk, linen, carefully emphasizing naturalness, natural finishes, the beauty of the selected style interior. Liquid wallpaper are good because they do not have seams, perfectly applied, repel dust and are easy to repair, if it became necessary. vinyl wallpaper, made of fiberglass are also used, nonwoven, coloring, washable.

More expensive "wood wallpaper" or gusvarblok, more like bunk than the traditional material. They are made of wood veneer, special, specially the dried, thermowood. These wallpapers are attached by means of small nails or "liquid nails".

Cork products look very original, created from the loose bark of the cork oak. They provide additional insulation construction, insulation. This product is excellent to decorate the interior in ethnic style.

See also:Summer kitchen at the cottage

Mural glued about the same as a simple paper, but only on a perfectly flat wall drawing will not be deformed, distorted. To suit various interior stylistics rural landscape theme or panorama of the modern metropolis, widescreen Image home lions or tigers in the natural environment of abstraction "screaming" colors and modest still lifes with flowers, wicker baskets.

The walls in the form of log

For only summer country house interior design with additional building materials are not necessary - enough to cover the logs or planks protective compounds, stains. All partitions in a house made of round logs. This home natural, environmentally friendly, suitable for country-style, rustic. Lack of registration is that the shrinkage of solid log walls is high enough, and update the fire and antiseptic coating have often enough.

To create a log apply only thoroughly dried logs - it will reduce the shrinkage, the probability of occurrence of mold, rot.

The materials used for the interior floor finishes

The floors in the house of the tree should be sturdy, no less durable than the building itself, a good blend in with the walls. The design consists of a rough base and waterproofing, heat-layer coating of the finishing. Between the sub-floor and the foundation created "airbag", retains heat. Frequently used filling, consisting of small chips, sawdust.

Their upper layer most often is performed from wide "deck" boards, but other variations are permissible:

- parquet;

- laminate;

- self-leveling floor;

- particleboard;

- linoleum;

- tile;

- carpet.

To wooden floor served for a long time, it did not change its properties under the influence of destructive factors (differences temperature, moisture, microbial damage), it is covered with antiseptics, varnish, placed underneath qualitative insulation.

Laminate

Making laminate most often mimics the texture of natural wood, at least - a stone, snake skin or a fantasy figure. The material itself is composed of four different layers of paper, impregnated with resin, fiberboard, textured paper with a picture "under the tree", the protective film coating. The thickness of the laminate is from six to twelve mm. Individual parts are connected to each other by studs and slots.

Before laying the foundation created - concrete, cement screed, which should be as smooth. The coating is dried for at least 40-60 days, from above, under the laminate itself, the roll substrate is placed. heating is not recommended to put the material on the floor.

When using adhesive bonding parts selected repellent adhesive.

Linoleum

Linoleum - relatively long-lived, low-cost coating, suitable for any room. The variety of colors, patterns, textures, materials base allows it to pick up to any interior style. This embodiment requires as flat, smooth surface for stacking - as the substrate is often used plywood. Linoleum is resistant to mechanical damage, it is unacceptable to strengthen the base of the nails - only glue, double-sided adhesive tape, and is fixed in the baseboards cramped rooms without additional materials.

If the room is large, it requires several bands laying linoleum then glued joints or joined with tape "cold welding".

carpeting

Carpeting has high thermal insulation, noise protection properties, which is accounted for in homes, consisting of two or more floors. Carpet refers to the web material is processed sides, a huge variety of colors, patterns. It is quite durable - lasts more than 15 years, is not afraid of wet cleaning, produced both from natural and synthetic fibers. Different types differ in the pile density, the thickness of the base - the thicker the carpet, the warmer it will be released next floor.

Bedroom, living room, children's suit include the long options - 30-35 mm, in the hallway, corridor - a short-nap, 3-6 mm.

self-leveling floor

Independently produce filler layer is difficult, because usually invited experts. Decoration with a solid, multi-color, format "three de" - the top layer looks transparent, and under it "bloom" bulk flowers, splashing waves of the sea, the birds are flying, floating clouds, and others.

These floors are usually lay on top of the concrete, carefully aligned surfaces. When it comes to the old house, which originally had a wooden floor, made cement on its surface, which, after it is completely dry, poured floors.

Parquet board, massive

Wood floor perfectly preserves the natural, the best microclimate for human health. He is the most durable, hygroscopic, but it is important not to be mistaken with a choice suitable for a particular species of premises:

- wood, richly secretes resin (pine, spruce, cedar, fir, larch), not suitable for places where there are changes in temperature or high humidity - kitchen, saunas, bathrooms with heated floors, the space around the fireplace and etc .;

- conifers are ideal for living rooms - bedrooms, living room, nursery, because among other things, release agents, disinfecting the air quality;

- linden, oak, beech, suitable for extremely wet areas - water it almost is not afraid;

- maple, cherry have high decorative properties, and with proper treatment, able to mimic the more valuable timber species.

See also:Choosing the design of stairs

Pre-finished flooring is usually treated with wax or varnish over it suitable toned color scheme.

Ceramic tile

Ceramic decoration, as well as most types of stone in the "warm" wooden buildings is rarely used solely for non-residential, utility room. Tile looks good in the room toilet, bathroom, kitchen, hallway. When laying tiles in wooden buildings, it is recommended the use of "sliding" guides that do not pass the natural deformation of the house during shrinkage on a tiled floor.

For a wooden house is best suitable tile, stylized natural veneer of valuable timber.

Stucco

Ability to design in his own hand-built housing is much greater than in a city apartment - the height of the space here is limited only by imagination, desire, the hosts finances. Finishing the ceiling lining most often produced from wood, at least - with the help of drywall, which is then painted, plastic sheeting, stretch film or fabric designs.

Wood

Finishing made of natural wood - a popular, best option. Such coating most environmentally friendly, it is executed as an array of expensive types and from inexpensive lining, plywood. Desirably, the moisture content of the materials does not exceed 15-18%: then the deformation will be minimized, the coating - smooth.

when the small chamber, - If the coating is selected linings, it is placed in the same direction in spacious well separated individual zones by means perpendicularly stacked panels or their various colors. When the room is made "antique", the individual elements are decorated with carved, hand-painted.

Plywood - the budget option. It is suitable for unheated, damp rooms. The topsheet is usually made of maple, alder, birch, walnut, middle - pine, spruce and fir.

plasterboard structures

Plasterboard sheathed any surface thereof easily perform two-three-tiered ceiling of any size, configuration. Ceiling tiles lighter and thinner wall, they are mounted on a frame made of wood, at least - the metal. On this ceiling is easy to place a lot of spotlights, LED strips, separately each level is highlighted on a contour, decoration in plaster or plastic, hand-painted, various images.

plastic panels

Plastic - the material simple to install. When the rough ceiling smooth enough panels are mounted directly on it, but if not - at first going to crate of wood or metal. The disadvantage of this artificial material - it is almost not breathable because between elements often picks up moisture, fungus growing mold. Of the benefits - in case of damage the individual elements are easy to replace.

For a wooden house suitable for ceiling panel light wood color with a corresponding pattern.

Stretch ceiling

The main plus of tension structures - they do not deform, even at a considerable shrinkage of the wooden buildings. If the design is still slack, it can be a little "pull up" - it is desirable that the master did. The material is stretched slightly below the beams, which affects the height of the ceiling - it should be considered when installing in low rooms. This design can be used in a single ensemble with plasterboard, while creating layered compositions. Depending on the interior style, film or textile web itself decorated different color or monochrome images: floral patterns, geometric designs, landscapes, abstractions, birds, clouds, butterflies, kittens, fruit, fish, palm trees and et al.

Experts disagree on when to start the installation of suspended ceilings. Some propose to do so almost immediately, others - one and a half or two years, when there will be complete construction of shrinkage.

Styles wooden house

The style of the interior for a private home, with the right approach, fit almost any but the most common:

- country;

- Provence;

- rustic;

- classic;

- Art Deco;

- Empire;

- minimalism;

- Scandinavian;

- loft;

- ethnic;

- modern.

Various design options for different views, the number of decoration, decoration methods. In minimalism, the interior is done mostly monotonous, hardly has any decor, loft deliberately underlined volumetric ceiling beams, the coating is forced sostarivayut, and gas and water pipes is not hiding. In the ethnic style of the room covered with opaque protective structures for art deco say gloss lacquer. Rustic involves rough, "clumsy" furnish rooms, decorated with Provence nice little floral prints on smooth walls. Classic is made in bright colors, often full of multicolored country.

conclusion

The interior design of a small log cabin, spacious cottage in the suburbs is done with his own hands or with the participation of invited experts, who will furnish, in accordance with the wishes of the customer "under the key". A modern wooden house will give warmth more than one generation of tenants and high-quality, eco-friendly materials in order maintain their health. Step by step workshops on domestic work is easy to find on the Internet, on the pages of periodicals.