Content:

- What is orthophosphoric acid?

- Precautions

- Removal of rust

- Etching of parts with full immersion

- Application of acid to the surface

- Removal of rust from the surface of bathtubs, toilets and washstands

- Rust converter

- What is better to choose?

A common "disease" of metal( steel and steel alloys) is rust. It is formed under the influence of oxygen, carbon dioxide and water. Scientifically speaking, this is a chemical reaction, as a result of which hydroxides and iron oxides are formed. At the first appearance of rust, it is necessary to clean the surface of the metal ware and protect it, because, unlike patina on bronze, rust on steel does not create a protective film.

Oxides or hydroxides( oxides) can be purified in several ways:

- by mechanical;

- chemical;

- with sandblasting equipment.

For the chemical purification of oxides, orthophosphoric acid is suitable, although mechanical and chemical treatment are most often combined.

What is orthophosphoric acid?

Orthophosphoric( phosphoric) acid, a water-soluble product of inorganic origin, is available as an 85% aqueous solution of a syrupy, colorless consistency. They use it in various industries, including food. It is one of the main components in the production of phosphate chemical fertilizers, and is also used in dentistry.

In the production of household chemicals, this acid is also used quite actively - it is present in almost all factory tools for controlling rust. But it is based on primers for metal, and the rust converter contains it as the main ingredient.

Precautions

If it is necessary to remove chemical rust, first of all you need to take care of your own safety - prepare a respirator and rubber gloves. Phosphoric acid is an aggressive substance that can cause skin burns, and its evaporation - burns of the respiratory tract and acute poisoning. In addition, it is fire and explosive.

All work must be carried out in well-ventilated areas, and do not allow skin to enter the body. If this happens, you must wash the affected area under running water. When a chemical burn on a large area, you must immediately go to a medical institution.

Rust removal

The advantage of using orthophosphoric acid for chemical rust cleaning is that it not only removes the loose mass of oxides, but also creates a thin protective film. The mechanism for creating such protection is that the acid, by eating and absorbing iron oxide, phosphates the surface. Those who worked with this substance could observe that after processing the metal and drying on its surface, in place of a reddish coating, a greyish film, oily to the touch, forms.

Depending on the degree of corrosion and the size of the part or product to be cleaned, different ways of removing oxides can be selected:

- etching the part with full immersion in solution;

- single or multiple surface acid treatment with a roller or spray gun;

- application on metal with preliminary mechanical cleaning.

Etching of parts with full immersion

If there is sufficient phosphoric acid and the correct capacity, it is easiest to remove by complete immersion. To do this, perform the following:

- degrease the part with any detergent and rinse it;

- fill the container with a solution with the following ratio: 100-150 g 85% acid per 1 liter of water;

- immerse the part in a container and leave for 60 minutes, stirring the solution from time to time;

- get it and rinse it;

- prepare a neutralizing solution in the following proportions: 50% water, 48% alcohol, 2% ammonia;

- rinse the part with a prepared solution, and then with clean water and immediately dry it.

You can not skip any of the above steps, since they are all interconnected. For example, if the degreaser is not processed, the etching will be uneven, since this acid does not corrode organic contaminants, and it will be necessary to clean up the problem areas further. This method is suitable for parts with any degree of corrosion, however, the larger the rust layer, the longer it takes to clean.

Advice

If after the final rinse immediately do not dry the surface, then immediately it forms hydroxide. Drying can be performed in any way, including convection.

Application of acid to the

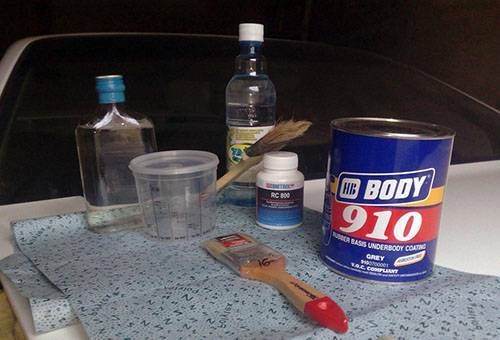

surface If the dimensions of the part are large, there is no suitable capacity or insufficient acid, it can be applied to the metal surface using a sprayer, roller or brush with natural pile. In this case, it is necessary to take into account the degree of corrosion. In the event that the layer of rust is large, then it is necessary to apply the combined method and first remove the surface layer of loose mass mechanically. This can be done manually or with the help of a grinder, on which a nozzle is placed - a metal brush or a petal circle.

After mechanical cleaning, it is necessary to degrease and apply an aqueous solution of acid, while trying not to make omissions. Two hours after application, it is possible to do the washing with a neutralizing solution, and then finish washing and drying. With little corrosion, mechanical devices can be dispensed with, although it may be necessary to reuse

.

. An inhibitor, catapine, can be added to the solution with acid, which inhibits the chemical process and prevents reaction with unoxidized metal. It is added in an amount of 1-2 g per liter of water.

Removal of rust from the surface of bathtubs, toilets and washbasins

Orthophosphoric acid can also be used as a household chemical. She perfectly copes with cleaning the traces of rusty water in the toilet bowls and enameled tubs. It is not suitable for acrylic bathtubs only.

Application for faience and enamel surfaces:

- 100 g of 85% acid must be added to 500 ml of water;

- degrease the surface with any detergent;

- with a brush with natural nap to treat the contaminated surface;

- after a few hours( from 1 to 12 - depends on the accumulation of oxides) wash acid with a solution of soda - 1 tbsp.spoon per liter of water.

Advantages of such a method of cleaning rust - there is nothing to rub, so the enamel is not broken. Information for the hostess who uses Coca-Cola to clean the red-tipped plaque: namely orthophosphoric acid, present in a small amount in this drink, gives such a result. It is much more effective to use the active substance in the proper proportion, and to use the drinks as directed.

Advice

When handling acids, do not forget the safety rules. Do not allow the chemical to contact the skin, and if this does happen, immediately rinse with warm water and soap.

Rust converter

The rust converter( rust modifier) is a solution of the same orthophosphoric acid, but with special additives. Depending on the additives, these drugs are divided into several groups:

- primers,

- stabilizer modifiers,

- rust converters.

As an example of the first group, the EVA-0112 primer consisting of two base components and 85% acid can be brought. It is used as a base for paint for steel products. The converter "Zincar" also contains orthophosphoric acid with the addition of zinc and manganese salts. Due to these additives from the converted rust, a hardened protective layer( metal alloying effect) is obtained. Before using the inverter, it is necessary to read the instructions and apply the formulation only in accordance with the manufacturer's recommendations.

What should I choose?

When choosing a rust remover, you need to focus on the place of its application. To clean parts by the method of full immersion requires a large volume of acid. Here, the acquisition of 85% concentration of orthophosphoric acid will be justified from both a practical and an economic point of view. If you need to not only remove the rust, but also create a protective layer for the paint, then the self-made solution will not work. In this case, it is better to buy a factory converter with all the necessary additives.

You also need to consider whether a primer coat will be applied or not. Converters-modifiers increase the hydrophobizing and inhibitory properties of the primer, but are not themselves a primer. But after processing the converter primer, you can immediately cover the metal with paint.

In conclusion, I want to emphasize that orthophosphoric acid creates a protective layer for the interoperational period. That is, without coating the coating, the metal will be corroded.