- Preparation of

- Device and operation of

- device Frequent breakdowns of

- More troubles:

No home appliance, even the most modern and high-tech, is immune to malfunctions. Including washing machines. But today, manufacturers are trying to create such designs that even a person without experience will be able to correct simple breakdowns without resorting to the services of masters. Let's talk about repairing washing machines.

to the contents ↑Preparation of

Self-repair of washing machines at home is not an easy matter, if it is well prepared, but it all depends on the breakdown. To begin with, a number of general recommendations should be followed.

Recommendations:

- To get the diagnosis faster, you can see if the device issues an error code, and check it with a list of codes for your model.

- If there is a reason, prepare all materials and tools in advance. So you save a lot of time.

- Be sure to check the operating instructions of the device before starting the diagnostics.

- Follow the safety procedure - repair the washing machine only when it is disconnected from electricity and water.

Important! Just in case, in advance, find the phone of a good repairman - he will help you if you fail.

Let us examine further with the tools necessary for self-repair.

Tools

Of course, what tools and materials you need in the process of work - will depend on the specific failure. But there is a universal kit that any home master will need:

- Screwdriver set: cross and flat;

- clamps for clamps;

- set of wrenches;

- pliers;

- cutting pliers;

- sealant.

Important! Keep tools close at hand, so you do not have to spend time on the right device at the moment, running around the apartment.

For the correct diagnosis it is necessary to understand how the washing machine works and how it works.

to the contents ↑Device and operation of the

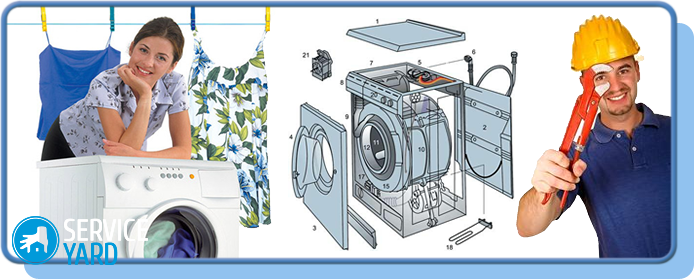

The work of the washing machine is provided by a set of interconnected parts and systems.

Important! Not only the complexity, but in principle - the possibility of repairing washing machines, depends directly on which particular node went out of order.

Basic parts:

- vent for drum;

- water reclamation and distribution system;

- intake valves;

- detergent drawer;

- suspension;

- counterweight;

- siphon;

- emergency opening system;

- drain system;

- shock absorbers;

- water level sensors;

- electronic board;

- drum;

- heating element;

- engine;

- external device management system;

- connecting hoses and pipes;

- drive belt;

- pump;

- door and adjacent seals, sensors and latches.

Now we'll figure out how the device works.

Operation of the

The principle of operation of all washing machines is the same. Differences can be in washing modes and additional functions. Let's talk about the general principle of the device:

- To allow water to flow into the tank, the intake valve opens.

- After filling the tank with water to the required level, the sensor is triggered and the supply valve is closed.

- Then the system responsible for water heating starts working. Its main element is the heating element, it heats the water to a certain temperature. If there is no temperature in the device of the sensor - the heating goes on a timer.

- Together with the TEN, the motor of the device is started, and turns the drum rotation, but not at full power. The drum rotates at short intervals.

- After - the pump pumps out dirty water, the valve re-opens and pours clean water.

- Then the valve closes, the motor is connected again and the device operates in rinsing mode, at low speed. After - the water is pumped out.

- The next step is spinning. The drum starts to rotate at maximum speed.

Important! Please note that the pump is always on during the mode.

We have familiarized ourselves with the device and the basic principle of the device. Let's turn to possible breakdowns and the question of how to repair washing machines at home.

to the contents ↑Frequent breakdowns of

The most common problems are not so many, we will deal with the main ones, their causes and talk about their elimination.

The device does not react to the activation of the

. For this fault, the following reasons are possible:

- Incorrectly selected washing mode - the device reset will help to correct the situation.

- The door of the appliance does not fit securely to the body. Check the door, the seals between it and the tank, as well as the door latches.

- The machine may not be connected to the network. You should see if the cord, socket, plug of the device is working properly, and also whether the plugs are not knocked out. Or maybe the device is simply disconnected from the outlet, then the washing machine repair is not required.

- Also, the appliance may not switch on when there is no water flowing into it. For diagnostics, first check whether the supply taps are open.

- If the wiring is damaged, the unit will also refuse to operate. For diagnostics, it is necessary to disconnect the device from the power supply, remove the removable panels of the housing, check whether the contacts have oxidized, and if necessary, clean them. If the contacts are all normal - they ring the cord to the cliffs.

Important! A common cause of this kind of malfunction is the breakdown of the timer. For diagnostics, you need to switch programs until the drum starts up. If this does not happen - the timer is checked, and in case of its malfunction, change.

The machine does not pump water

This option also assumes various reasons:

- The water supply is disconnected. Check the valves and valves.

- Inlet hose is deformed, check it, rinse as necessary, correct.

- Filter element clogging. In this situation, close the valve that supplies water to the appliance, carefully disconnect the hose, and drain the water from it. After - the filter is removed and washed under running water. Then the system is assembled in the reverse order. This will be the entire repair of the washing machine.

- Damaged valve. If the filter passes dirt, they can easily get on the valve and it will break. If this happens, the part will have to be replaced.

Another reason is a malfunction in the water level sensor. If the water in the tank exceeds the required level, air is compressed in the control system, and a protective mechanism that blocks the water supply is triggered. A breakdown is possible if the system is clogged.

Another reason is a malfunction in the water level sensor. If the water in the tank exceeds the required level, air is compressed in the control system, and a protective mechanism that blocks the water supply is triggered. A breakdown is possible if the system is clogged.

To return the device to the operating state, it is necessary to perform a number of actions:

- Checking the tube on the switch: if it has hardened at the end, it is removed, cut off and installed back.

Important! For testing in the tube you can blow. If you hear how the switch switches - it means the work is done correctly.

- After - loosen the hose clamp that connects the tank and pressure chamber.

- The chamber is cleaned and inspected for damage.

- Then check the switch. It is called by a multimeter and is replaced if damaged.

Another problem with the washing machine is problems with water recruitment.

Slow water set

If the machine takes too long to collect water, the following fault variants are possible:

- A blockage or kink of the hose, through which water enters the device. The hose can be easily dismantled, rinsed and installed into place smoothly, without kinks.

- Filter clogging - in this case, the same as with the hose: the filter is removed, washed and installed back.

- Low water pressure. In this case, it is worth checking whether the valve responsible for the water intake is fully open.

Important! If the valve is all right, then the problem is in the pressure of the central water supply. Repair of the washing machine is not required - this question should be addressed to the experts of the housing office.

No water heating

This type of fault can also cause a variety of reasons.

The water level sensor

is broken. The sensor does not recognize if the device is full, respectively - it does not switch the device to heating mode. To determine if the sensor is broken - it is called, it is replaced, if necessary.

Scum on TEN

Rigid water and the lack of good filters over time make themselves felt - on the heater appears lime sediment. But this problem is easily solved. The device is dismantled, remove the heater and clean it of plaque.

Important! If the element is completely destroyed, then the repair of the washing machine implies the replacement of the TEN.

Oxidation of the contacts of the heater or their weakening

The contacts can be tightened, cleaned and ringed to the cliffs. If they are found - the heater is replaced.

Temperature Sensor Malfunction For the diagnosis it is necessary to ring the part. In the event of a malfunction, the sensor can switch off the heating earlier than necessary.

Another version of the breakdown - when the device starts, but does not bring the mode to completion.

Stopping the

The cause of this malfunction is a lot - from simple to complex:

- The mode switch is paused.

- The supply of electricity was lost. Probably, knocked out plugs or in the socket the tension has disappeared. Filter or hose clogged.

- Blockage or breakdown of the pump. In this case, the pump is removed, the impeller is checked, it is cleaned, if necessary - the washing machine is repaired, replacing the part with a new one.

- Intake valve clogging.

- Depressurization of the drain system. Check all connections.

- Problems with the temperature sensor.

- Faulty heating element

- Timer failure. Repair of this part is too expensive and pointless. It's easier and cheaper to buy and install a new timer.

Important! Also you could break down the motor. To check it you must:

- remove the belt from the engine;

- install the program of pressing;

- turn on the power supply;

- check engine operation.

If there are no rotations of the motor, it is removed and disassembled for further testing.

No rotation of the tank

The simplest thing is that the settings are lost and the device is paused. Correct the situation by choosing the correct mode.

More options:

- The drive belt has slipped or torn. If there is no damage on the part - install it back, if there are cracks or it has torn - you will have to install a new part.

- Do not lock the hatch door. Because of this breakdown. The drum will also refuse to rotate. Check the door and housing connections, as well as the door latch.

Important! It is also possible that the motor has broken down. How to verify it is already described above.

No draining

In this case, the following reasons are possible:

- Incorrectly installed mode switch - check if the pause in the washing cycle is possible.

- Drain or kink the drain hose. To eliminate the malfunction, the hose is washed and installed without kinks.

- Filter drain plug. If the reason in the filter - it needs to be removed and washed.

- Pump clogging is another reason why the machine does not drain the water.

- Breakdown of the pump. In this case, the pump is removed and the rotation of the impeller is checked. After - the pump is rinsed and contacts are called to the cliffs. If necessary, the part is changed.

Important! Also, the cause of the failure may be hidden in:

- contacts;

- timer;

- water level sensor.

Of course, all possible faults can not be described, therefore, briefly a little more about possible options.

to the contents ↑More problems:

- If there is water flowing from the device, there may be problems in the hose: it could jump out of the sewer, the connections might loose or it could crack, or the door does not fit snugly against the body of the device. It is also possible that the sewer system is clogged.

- In the presence of extraneous noise, most likely in the tank were objects( for example, keys, coins, etc.). Disassembling the tank is a very time consuming task, so make sure that the pockets are empty. Also, you need to check and lock the hatch door - the lock might be damaged. Another option for such a breakdown is possible if there are problems with the belt of the device or "flew" the bearing.

- The strong vibration of the device most often indicates its overload or unbalance. Another device can vibrate and even jump when mounted on an uneven surface. Adjust the legs, check the level to see how well the device is level. The heavier damage is the breakage of the suspension spring and the weakening of the counterweight attachment.

- The door is locked - the door lock can still function for 2 minutes after the end of the wash cycle. Also, this kind of malfunction is possible when the interlock switch breaks or if there is still water left in the tank.

If your washing assistant has a problem, be sure to read the instructions first. It is possible that you will be able to repair the washing machines yourself. If in the course of repair you have difficulties - the best solution is to contact a qualified specialist.