- Application areas of

- construction stapler Advantages of

- tool Types of staplers

- Mechanical

- Electric stapler

- Pneumatic stapler

- Staples for stapler

- Which construction stapler is better?

- Useful advices:

Today we would like to talk about a very simple, but necessary and interesting tool, like a construction stapler. And although he has a fairly narrow specialization, he is able to perform the "1001" operation. This tool is functional, durable, used in many areas.

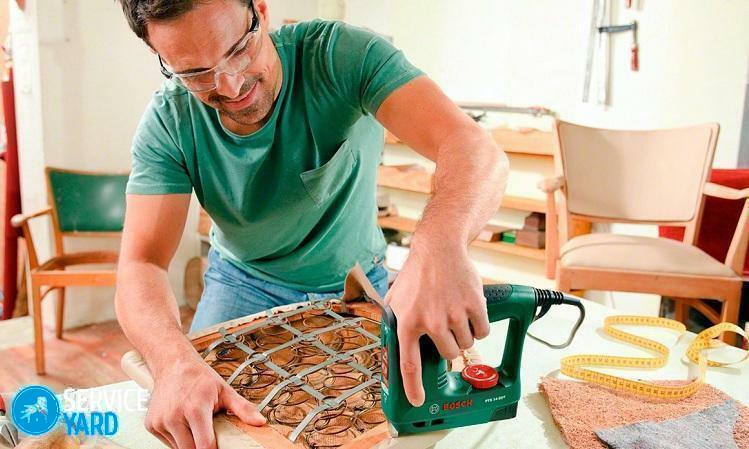

When you need to fix a bundle of paper, we use a clerical stapler, and if you need to quickly attach the carpet to the floor or pull furniture, then the construction stapler comes into play, or as it is called a tacker. So, a furniture stapler - how to choose the one that is most suitable for a particular task.

to the contents ↑Areas of application for the construction stapler

The history of the stapler begins back in the 18th century, when this tool was first used in France for clogging staples. And already in the 19th century, in connection with the development of book printing and printing, this tool received a new round of development. In 1866, the mechanism for the joining of paper sheets was patented, and a year later received a patent mechanism for joining thin brass sheets.

Indeed, the true recognition of stapler or taker was received quite recently, when it began to be used in construction. He is able to easily replace the hammer, and do it very effectively. In addition, if previously the tackers attached the material with only staples, now they can already clog nails or even mounting pins.

What can a stapler do?

When wondering what kind of stapler is for furniture, how to choose the right tool, it should be borne in mind that the modern device can perform two basic types of work:

- Beating one material to another. Often the basis is the wood or its derivatives( OSB, chipboard, plywood), plastic, but attach to the base everything that there is an opportunity to pierce.

- Stitching of equivalent parts with a bent staple. This connection is very reliable.

This tool is very fond of decorators and craftsmen. It is also widely used in construction and production. Here are just some of the operations that can be performed with a stapler:

- Fastening of structural elements and furniture upholstery.

- Drapery.

- Installation of bitumen shingles and roofing materials.

- Fixing on the frames of posters, reproductions, canvases.

- Nailing to skeletons of sheet materials - OSB, fiberboard, chipboard, foil, plywood, sheet metal.

- Lining surfaces with different materials.

- Assembling floors from a pile of boards.

- Mounting of membranes, films, heaters, insulation materials.

- Manufacturing of subsystems, bridges and modules.

- Fastening to the windows of the glazing beads.

- Installation of film greenhouses and greenhouses.

- Fixation of carpets.

- Sewing of plasterboard.

- Gasket of low-current and power electrical cables.

- Assembly of packaging frames and pallets.

- Punching the perforated.

With all these functions, a mechanical stapler may not be able to cope, but a pneumatic or electric taker is much more productive. Therefore, below we will consider how to choose a furniture stapler for the home, depending on the tasks assigned.

to the contents ↑Advantages of the

tool Due to the uniqueness of its design, the construction stapler has a lot of advantages:

- Installation takes a small amount of time compared to hammer work.

- Nailing materials do not take a lot of physical strength.

- High degree of safety. All sharp details of this tool are hidden inside the box. For non-mechanical devices a fuse system is used.

- When working with a stapler, one hand is always free and it can support the material.

- Ability to use in hard-to-reach and uncomfortable places.

- There is no need to pressure the instrument. This is very important in the process of working in an unstable position, for example, standing on the ladder.

- Light and precise impact transmission does not damage the workpiece, for example, during glazing.

- A spring piece easily breaks through. If the part that is nailed springs, then, unlike the hammer, the taker can easily handle it.

- Multifunctionality. Materials can be different: self-tapping screws, nails, staples, due to which the functionality of the tool increases.

- Does not vibrate, so there are no scratches or chips on the surface.

- Easy to maintain and operate.

- Durability, reliability, thanks to a small number of moving parts.

- Consumables are not subject to corrosion.

Types of

staplers There are three main types of tools:

- Pneumatic stapler.

- Electrical.

- Mechanical.

Which stapler for furniture is better - it is necessary to decide on the basis of their specific needs.

to content ↑Mechanical

This option is considered to be the simplest in a constructive way. It is this type of sticker that the house lovers like best. Spring, straightening, clogs nails or staples.

Important! The mechanical appearance of the stapler is the best option for household needs. With his help, you can collect new furniture after delivery from the store, make minor repairs and use it for other "home trivia."

Advantages:

- Does not require special skills in the process of operation.

- Simple construction.

- Simple care. All you need for a mechanical stapler - sometimes lubricate it with a simple lubricant.

- No wear parts in it.

- Compact, lightweight.

- Absolute autonomy. The tool is always ready for use, it does not need wires, batteries or batteries.

Choosing a quality tool

When choosing this tool, you should pay attention to the following:

- If you decide to choose such a small stapler, it is better - if its body is collapsible, fastened not to rivets, but to screws. So you will have the opportunity to clean the tool, and if necessary - to eliminate minor problems.

- It's better that the body material is strong enough. Give preference to modern light alloys. They combine a light weight and increased strength.

- It is desirable to select the shock mechanism on a spring spring. It is much easier to work with it, there is practically no payback.

- The adjustment mechanism of the punching force is the most important element of such a stapler. With the help of a switch or a knurled wheel, the tool can be adjusted to a material of a certain hardness. DSP sheets or plastic require the maximum spring potential. For this reason, the greater the potential, the easier it will be to insert a bracket into the surface.

- It is worth paying attention to the width of the clip and the maximum allowable size of the consumable material in order to choose a construction stapler for the house. A classic option is to equip the tool with a U-shaped bracket of a certain thickness and width with different lengths of legs. Also there are staplers that produce mounting by a U-shaped bracket.

- The store must necessarily close well. It is better - if the staples can be put in the tool( as in the clerical), and not pushed with the clip.

Important! It is very convenient, when it is possible to control the remaining number of staples in the store through the inspection window.

Recommendations:

- Double-impact mechanism for a mechanical tool will not be superfluous. It is used in case the clamp does not completely enter the surface of the material. This function makes it possible to perform an additional impulse on the not shackled bracket. In this case, the supply mechanism is turned off.

- To get a stapler in a hard-to-reach place, it's best to choose a tool with a protruding spout.

- If you need a tool that works with rounded and straight staples, then give preference to the universal tacker. It can also work with small pins and nails.

Electric stapler

Unlike the mechanical stapler, the electric stapler is much stronger and more functional, since all the hard work for us is performed by the motor. The electric version of the stapler has all the advantages that a simple tool, except, of course, autonomy, since it requires an outlet for its operation. The problem will be solved by the battery, but then there is a problem with the capacity and mass.

Important! The power of such a tool can reach 1500 watts, which makes it possible to clog the rigging to a rather large depth.

In order to protect the user from electric shock, manufacturers use plastic casings, and on the handles there are rubberized lining. The winding and the power cord of the motor are double insulated.

Advantages of

When choosing a furniture stapler for a home, one must take into account the main advantages: a similar tool:

- High performance.

- Functionality.

- High reliability of fixation.

- Speed of the operation.

- Durability.

- The ability to drive into greater depths.

- Protection against accidental starting.

- Various adjustment of force of impact: stepped, smooth.

- There is a device for removing fasteners.

- Pulse frequency monitoring.

- Possibility of impact by two staples.

- Possibility of automatic reusable impact.

- Depth sensors are present.

- The shot is from the pressure on the tip.

Disadvantages:

- The relatively high cost of the device.

- The work space is limited by the length of the cord. A decent length of power cable - 5 or more meters, is considered a rule of good taste.

Important! The weight of any of the electric models will be greater than the mass of the mechanical analog. Sometimes the weight of an electric tool can exceed 2 kg( add more engine mass here).

Useful tips for choosing:

- When choosing a furniture stapler for a house, first of all, you should start from its rate of fire, that is, the maximum number of pulses for a certain time.

Important! Average models are capable of 20-30 rounds per minute.

- If you decide to purchase a furniture stapler with a battery, then pay attention to the capacity, as well as the speed of the full charge of the battery. Well - if the model of the device has a second power unit or it is possible to replace it with another battery of the same manufacturer.

Pneumatic Stapler

This unit is compressed air. All tasks are performed just lightning fast. This is a fairly powerful stapler. In the mechanism of this type of stapler there is no main spring, and for it the work is carried out by a pneumatic cylinder, which receives air from the pneumatic distributor controlled by the pedal or by the trigger.

Important! Despite its power, this instrument has a fairly simple design of the technique. Stapler is easy to maintain - it needs only to be cleaned occasionally. In addition, it is durable - the only part that can eventually fail, this is a sealing ring, but the price of such rings is low, they are easily replaced.

Advantages:

- Easy to maintain and use.

- Instant fixation, regardless of the density of the substrate.

- The average weight does not differ from the mechanical version and is smaller in size than the electric one. All pneumatic models are within 1 kg.

- High rate of fire. A pistol that clogs one brace in a second is the norm.

- High performance.

- Compactness.

- Excellent handling of wide and long staples.

- High rate of fire.

- Contact and separate start.

- Availability of a locking system.

- Possibility of multiple impact.

- Possibility to adjust the impact.

- Removable filter.

- There is a mechanism against seizing staples.

Disadvantages:

- Together with the instrument you need to buy a compressor.

- Compressed air is required, and for some of the models - a separate power line.

- Limited range, which depends on the length of the hose.

- Suitable only for stationary operation.

Important! Such types of staplers have become increasingly used in furniture factories, small shops and construction sites, where every worker has his own equipped place, because neither the stapler nor the compressor can be moved anywhere. All operations will be carried out at lightning speed, and staples are easy to clog. Pneumatic models are rightly considered to be the best in terms of performance.

to the contents ↑Staples for the

Stapler When choosing staples for the stapler, proceed from the information given in the instructions on the machine and follow certain parameters:

- The depth of the staples, as a rule, varies from 4 to 14 mm. The choice of this parameter is determined by the nature of the work. For example, in order to tighten a chair with a tapestry, staples of 8 mm are suitable, and for carrying out work with felt, you will need to take staples 10-12 mm.

- Bracket type - must be agreed with the tool model. Marking on packages must be the same for both brackets and models. For example, if the staples are too small for the instrument, with one shot they can fly out one by one, in turn. In addition, the store may be skewed, because of which the tool can jam.

Important! Do not follow the recommendations of some sellers who advise to replace the brackets of one type with others. They may have the same depth, but their geometry, which is invisible to the naked eye, can be different, which can lead to device failure.

to the contents ↑Which construction stapler is better?

Construction stapler, how to choose? Pneumatic, electric or mechanical - it is necessary to pay attention to the size and type of rigging( staples), because this parameter indicates the purpose of the tool.

Consider the main types of construction staplers, and for which job they are suitable:

- Classic - suitable for home repairs. Has a mechanical percussion instrument. It is started by pressing the lever. Fastening: nails, as well as staples of flat type. However, he has a drawback: it is difficult to work for a long time in them - the hand is tired.

- Window - works with metal studs, not with staples. A mechanical device is capable of clogging studs no longer than 1.5 cm, pneumatic - up to 5 cm, and electric - up to 2.5 cm. The length of thin nails depends on the type of instrument.

- Packaging - is required when working with corrugated cardboard boxes. Paper is stapled much more securely than scotch tape. This stapler is found in two types - pneumatic and mechanical.

- Staple hammer - used to insulate the base of the floor or on the roof when laying the roofing material. It is more expedient to choose a model of this type, in order to use it where fast work is necessary. Staples are driven in every hammer blow to the metal, they are fixed due to inertia.

- For staple bracket - this tool is used when it is necessary to fasten two parts at a certain angle, for example, a frame for a picture or a photo. This type of apparatus is in the form of the letter "V".

Tips & Tricks:

- If you need a tool for doing housework, then look for a model that can clog a 12 mm bracket or a little more. It would be enough.

- When choosing a stapler, pay attention to the capacity of the store. The more consumable material is placed in it, the less often thereafter will have to fill in new ones.

- Try to use only "branded" consumables in order to extend the life of the instrument.

- If you plan to work with the tool not only at home, but also transport it, then buy a storage case. It is better to initially acquire a model in a branded case, so that the stapler can be conveniently stored and transported.

- During the purchase, pay attention to the size of the handle: its length should be approximately equal to the width of the palm - in this case, it will be easy to press.

In the question of how to choose a furniture stapler for a house, first of all, it is necessary to be guided by its purpose. So, for repair of furniture it is better to use a mechanical model, and for carrying out large-scale works pay attention to the electrical. If you intend to open your own production, the best option will be a pneumatic tool.