- Types of liquid glass

- How beneficial is it to use liquid glass?

- Ways to prepare a silicate mixture

- How to make a water glass with your own hands?

- Useful recommendations for the preparation of aqueous silicate:

Liquid glass is an aqueous solution of sodium silicate or potassium silicate. The areas of application of this material are very wide - starting from the pulp and paper industry, finishing with construction work. Very often this type of glass is used as an antiseptic in construction. The majority of those who are puzzled by the repair question arises: how to make a liquid glass with your own hands? In order to deal with this, you first need to familiarize yourself with the basic characteristics and methods of manufacturing such material. This will be discussed in this article.

to the contents ↑Types of liquid glass

As this type of glass dissolves well in water, specialists distinguish two types:

- Potassium glass. Potassium liquid glass is a part of many different building dyes, so it does not shine after it dries. In addition, it is resistant to negative atmospheric influences.

Important! Often it is used for the production of fireproof solutions and impregnations.

- Sodium glass. Sodium liquid glass has a more viscous and adhesive texture. The material perfectly interacts with various mineral compositions.

Important! Often this kind of material is used as a strengthening and waterproofing substance for building foundations.

to the contents ↑How beneficial is it to use liquid glass?

Silicate glue is used in various fields of activity, most often in construction and chemical. It is used as an additive to various building materials: ground mixtures, plasters and impregnating solutions.

Important! This glass is a very good hardening accelerator for various building materials.

The following substances and compositions are made of silicate material:

- Dyes.

- Antiseptic building mixtures.

- Fireproof and waterproofing compounds.

- Adhesive.

If you start using self-made liquid glass in repair and construction works, you will soon find several positive points:

- The material is durable and resistant to acid and atmospheric negative factors.

- The glass does not absorb moisture, that is, it is able to prevent damage to the treated structure.

- The material serves as a "protective shield" for decorative elements. It covers the surface of decorating structures, creating an antiseptic protective film.

Important! Using liquid glass in construction work is the right solution if you want to extend the service life to walls, ceilings or floors.

to the contents ↑Ways to prepare a silicate mixture

Despite the fact that the construction industry is developing very actively, the use of liquid glass is popular to this day. Making liquid glass yourself is quite difficult, but quite realistic. Since the material is practically not used as an independent substance, it is used in tandem with others( primer, cement).Let's consider several ways of preparing a silicate material.

Primer mixture

Do not work with the primer only with liquid glass, so make the mixture. Only three components are required for the preparation of the mixture: water, cement and water glass:

- Mix cement and an aqueous solution of silicate in a ratio of 1 to 1( i.e., 10 kg of cement + 10 kg of glass).

- Before mixing these two substances, it is necessary to dilute the cement with water.

Important! The main thing - do not forget to stir constantly the mixture so that it does not thicken strongly. If the primer still thickens, you can add a little water.

Refractory coating

This composition is used for furnaces and fireplaces in baths. The silicate solution is added at the last stage of the preparation of the refractory mixture. Make a mixture in small portions so that it does not have time to dry out and thicken heavily.

Waterproofing compound:

- The diluted silicate material adds to the dry cement, in a proportion of 1 to 10( i.e., 1 kg of silicate adhesive to 10 kg of dry cement).

- The resulting mixture begins to thicken and harden in the first five minutes, so it is recommended to use it immediately.

Important! If the solution has hardened, a little water can be added to it, but it is worth remembering that the waterproofing properties deteriorate. However, one advantage remains unchanged - preventive effects against fungus and mold.

to the contents ↑How to make a liquid glass with your own hands?

In order to make liquid glass at home, it does not require any special knowledge and skills. The recipe for silicate is quite simple:

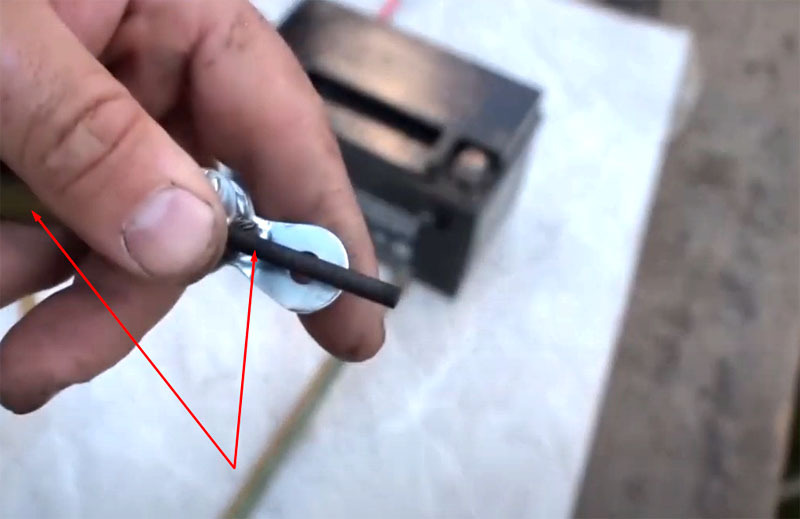

- In a large fireproof pot, one part of clean sand( without impurities) and four parts of soda should be covered.

- Gently mix everything and grind.

- The refractory container should then be heated to such a temperature that the contents melted.

- The resulting mixture should be washed from the pot with hot water.

- The resulting composition, that is, sodium silicate, is the water solution of silicate.

Useful recommendations for the preparation of water silicate:

- An aqueous solution of silicate has become an excellent solution for protection against dampness in cellars and wells. For 1 kg of water silicate is taken 10 kg of concrete, this composition is treated with walls of cellars and wells.

- It is recommended to stir the water silicate composition thoroughly with a brush or roller. The proportions of the components must be determined only after you have determined the purpose of using such a solution.

- If silicate is used as an additive in cement, do not forget to stir the mixture constantly. After applying the formulation, you should thoroughly wash your hands in soapy water.

- If aqueous silicate has got on the skin, it is recommended to immediately treat the contaminated area with running water.

- If you decide to treat the composition of the wall, you will first have to align and degrease them. For application of the substance, an ordinary brush and an airbrush are used. If you decide to make a more thorough and thick coating, apply several layers of mortar.

Important! Regardless of how you use water silicate - with other substances or yourself, always take precautions. Wear protective gloves, a mask and, if possible, special glasses.

In this article we have told you how liquid glass is, where it is applied and how to make it yourself. We hope that you will be able to apply this information in practice to make really lasting, high-quality repairs in your home.