The sewing machine not only makes even stitches on any fabric, but also accelerates the entire process many times. This is an excellent assistant for the hostess, even if she is not friends with the needles and threads from school work lessons. Modern models know how to sweep the edges of the fabric, make the same loops and even embroider beautiful patterns - no master can not do anything that clever technique can. But if you have not worked before with anything, it's more complicated than Grandma's "Seagull", it will be difficult to make a choice.

Contents:

- Best sewing machine manufacturers

- Principle of operation and device

- Types of sewing machines

- Selection parameters

- Which sewing machine to choose

- How much is the sewing machine

The best sewing machine manufacturers

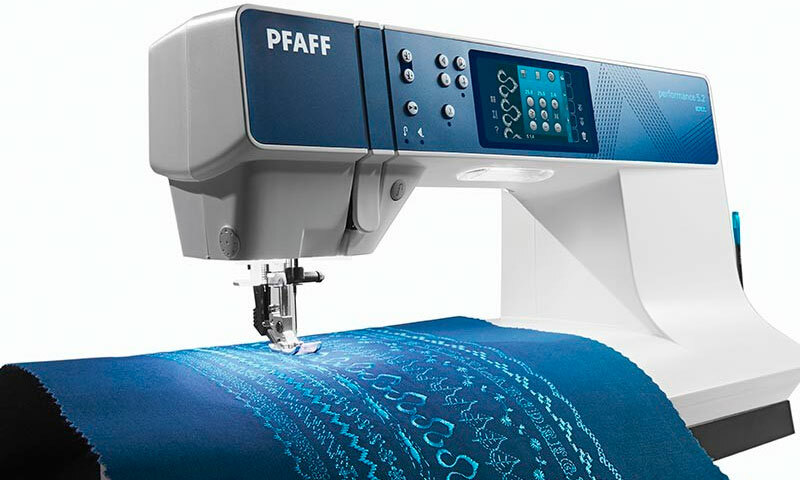

The best sewing machines are made in Europe( Switzerland, Germany, Sweden), in Japan and the USA.If you see the models of the manufacturers listed below, you can take it boldly - this technique is reliable and is always one step ahead in its functionality:

- Janome

- Pfaff

- Husqvarna

- Bernina

- Brother

The range of machines of these brands is quite wide, so if the eyesrun away, our review of the best sewing machines will help you decide on the choice. But in order not to overpay for extra functions, it is better to sort out how to choose a sewing machine for your tasks.

Principle of operation and device

Despite the greatly expanded capabilities of modern technology, the principle of sewing machines for the past 170 years has not changed. Inside the hull, the same system of shafts and levers, which the flywheel starts, hides. And it does not matter, it turns due to electricity or a grandfather's manual method. The main thing is to understand how this machine makes stitches.

As the machine elements are connected to each other by pull rods and shafts, when the handwheel is turned in motion, all the main working units come in:

- A working needle passing through the fabric passes the main thread;

- The bobbin begins to spin, feeding the lower thread;

- A shuttle is launched, twisting the threads together and forming a stitch;

- The conveyor moves, stretching the fabric to the length of the stitch.

To get started, you need to stretch the main thread through the guides and insert it into the needle's eyelet. Another coil of the same color is threaded into the bobbin and installed in a special socket under the needle behind the removable panel( sometimes directly above it - it all depends on the design of the machine).Next, put the cloth on the work table and lower the foot with the lever, pressing it to the transporter. All - you can start the flywheel and start sewing.

Types of sewing machines

Modern sewing machines, despite the fact that they perform approximately the same tasks, are divided into 3 large families in accordance with the type of control. This is convenient, since the number of operations, on which the technician is capable, primarily depends on the implemented system.

We will not consider obsolete mechanical models - their functionality and speed of operation do not go to any comparison with the capabilities of more advanced units. Let us dwell on the actual types of sewing machines.

Electromechanical

This type of aggregates from ancestors is distinguished by an electric motor, which drives the flywheel, releasing the seamstress both hands. And they will need it, since all the settings will have to be set manually with the help of handles and handles taken out on the body.

Pros:

- Simple and reliable design;

- Sufficient, though not the richest set of functions( usually not more than 20);

- Good maintainability, simple maintenance;

- Affordable price.

Cons:

- It takes time to learn and remember all the adjustments;

- Minimum of decorative stitches.

From electromechanical machines only one is required: to automate manual sewing. This technique is suitable for simple household tasks, when you need to repair clothes, trim kitchen towels or curtains, sew some accessory or a simple thing.

Electronic

Machines with a "brain", whose role is assumed by the controlling microprocessor. In his memory are stored programs for lines of varying complexity, as well as all the necessary adjustments. Such models are equipped with a display on which you can monitor the operation of the machine and set the basic parameters of sewing.

Pros:

- Ability to perform a large number of different stitches down to simple embroidery;

- Easy operation - just select the desired operation on the control panel;

- A set of automatic settings that do not require operator intervention;

- Availability of a display with information about the current mode or with prompts;

- Many models are started from the button, not from the pedal.

Cons:

- Requirements to the quality of current in the network;

- The complexity of self-repair.

This is the largest and raznosherstnoe family of sewing machines with a rich functionality - here there is a technique for professionals and novice craftsmen. With its help, you can create things of any complexity from a variety of fabrics, hinge loops and sew on buttons, decorate your models with decorative stitches, appliqués and even embroidery.

With computer-controlled

The most advanced models, in functionality, superior even electronic typewriters. In addition to their own programmatic control, they can be connected to an external PC and operate almost without operator intervention. The design of computerized machines is also different. In order for one unit to perform hundreds of different operations, the main groups of mechanisms are equipped with separate drives( sometimes up to 10 engines) and are able to operate autonomously.

Pros:

- The largest set of functions( an average of 500 different operations);

- Extended options for designing loops, including eyelets;

- Create your own, unique lines;

- Automatic selection of modes depending on the fabric;

- Sewing assistant, helping to pick up the presser foot, needle and other devices for a specific task;

- Most machines are equipped with an embroidery module;

- Some models work with memory cards.

Cons:

- Very high price.

The purchase of computerized sewing equipment is justified in cases where the sewing of complex and exclusive things is put on stream.

selection parameters We have already considered the types of control and even decided which one is preferable for different tasks. Now we will get acquainted with the main characteristics that will help with choosing a particular model of the sewing machine.

Lines

It is important to choose the optimal number of working and decorative stitches, and their variety will be provided by the manufacturer. In the simplest models of machines, even standard joints for joining the fabric will be at least 5 - enough to solve any household tasks. The main thing is that among them there are:

- a straight line;

- wrapping;

- is a secret;

- flexible;

- zigzag.

If you have to work with different types of fabrics or occasionally perform non-standard tasks, you can take a typewriter with 10-20 types of stitches. For beginners, this is definitely enough.

Decorative and embroidering lines are the lot of professionals. If you belong to this group or in the near future plan to perform super complicated sutures and machine embroidery, look for a computerized model with an embroidery unit. In any case, experienced needlewomen should choose a technique by the principle: the more types of stitches in the program, the better.

Knitting out the loops

This function is available in almost all modern models, but the way to perform button loops can be different: semi-automatic or fully automated. In the first case, you will have to "help" the machine to do its job, turning the product in the right direction - each loop is swept out in 4 stages.

In professional models, an automatic version is implemented - faster and more convenient. Such advanced machines are able to sweep from 3 to 10 different loops, including the most complex of them - with the eye. Accordingly, they are more often used in the atelier of the finished dress, but for home use there will be enough and one mode of the standard underwear loop.

Type of shuttle

Very many things depend on its design, so always make sure which type of shuttle is installed in your model before buying.

The rocking shuttle is the easiest option found in mechanical and inexpensive EM machines. It is noisy, not too bright and does not allow making stitches longer than 5 mm. In this case, the quality of the line, like the shuttle itself, can "float", and the breakage of the thread is not uncommon. To fill the bottom thread and adjust its tension in this case is also quite difficult, but the cost of the machine itself will be low.

The horizontal( rotating or rotary) shuttle is a more perfect design that meets on machines with an upper bobbin position. It is already built into the body and does not swing, but wraps around the axis, reducing vibration during operation. Another advantage of such a solution is that the lower thread is practically not entangled, which improves the quality of the seam. Alas, to regulate its tension in this case is also difficult, but it is easier to control the thread stock on the bobbin. The horizontal shuttle allows you to get a line up to 7 mm and a wider zigzag up to 6 mm.

Vertical shuttle - can boast of high reliability and does not confuse the thread during operation. The main difference from horizontal is simple adjustment of the interference. This function is necessary for seamstresses, constantly working with tissues of different thicknesses.

Basic adjustment

Sewing speed is an adjustable parameter. In the most simple electric cars it can be controlled by pressing the pedal: the deeper you heat it, the faster the lines fall. But if you spend at the sewing table all day, it's not too convenient. It is better to look for a model that starts from the button, and the speed is set on a separate regulator or automatically set by the program. In professional machines, it can reach 1300 rpm, but this is the level of experienced masters. Usually, the figure is 800-850 st / min.

The puncture force is often directly related to the sewing speed - so the laws of physics work. When buying the simplest EM-models you can focus on the power of the unit itself - the higher it is, the easier the needle will penetrate a thick fabric. Semi-professional typewriters usually have engines of 70-80 watts. If this figure is lower, then you can work only with thin materials. In more expensive models, the puncture force is already regulated by the operator or by the machine itself due to the built-in electronic stabilizer.

The pressure of the foot - here, too, it is better to choose in favor of an adjustable or adjustable clamp, as in professional computerized models. So it will be easier to work with fabrics of different thickness, without losing the quality of the stitch.

Which sewing machine to choose

1. For those who do not want to fight with threads and needles anymore, sewing the next torn things of children, and do not want to waste time on hiking in the atelier to trim new trousers, there will be enough simple electromechanical typewriter. Choose an inexpensive, but functional model with a dozen basic work lines. It is better that it was easier, otherwise you are too lazy to get it out of the closet when it is needed.

2. Those who sew at home a lot and often, on the contrary - need a heavy machine with a metal bed and the same reliable stuffing. And it does not matter - electromechanics is this or an electronic model - the main thing is that it has enough for your purposes a set of various stitches( no less than 20).If the house has a small child or you sew at night, immediately choose a technique with a horizontal shuttle so as not to make noise.

3. Advanced electronic or even computerized models( if revenues allow such a purchase) are suitable for skilled craftsmen. Here the number of working stitches will already be measured in hundreds, and additional useful functions will make it as easy as possible. Your car will need a speed adjustment option, a puncture stabilizer and the ability to change the presser foot - all this will work with any kind of fabric.

4. Professionals who create exclusive accessories, custom clothes and souvenir products "on the flow" need a computerized model with a large selection of decorative stitches, several variants of hinge loops and preferably with an embroidery unit. Useful and sleeve platform for working with small parts of clothing. The shuttle is only vertical or horizontal, otherwise there will not be a high quality of the line.

5. Additional functions will expand the capabilities of the technology and make it easier, but try to pick up the machine with the options that you will really use. For example, the reverse, built-in thread-weaving, bracing and trimming threads accelerate the process and will be useful for everyone. But the mirror image of the picture or programmable repeating elements, if you do not embroider, may not be required.

How much is the sewing machine

The price of a sewing machine is largely determined by its technical equipment - for additional "skills" of its assistant will have to pay. But for each type of technology there is a price threshold, below which it is not desirable to descend:

- Amateur EM-machine with good functionality should not be cheaper than 5000-6000 rubles, but it is not more expensive to buy this equipment 10-12 thousand.

- Semi-professional models with electronic control unit, depending on the number of operations performed, cost more - from 12-15 to 100-150 thousand.

- For most craftsmen who only cover their family and a small circle of acquaintances, there will be enough machines available for 25,000-4,000 rubles. It can be both electronic and computerized models.

- In a professional studio you need machines from 50 thousand rubles and more. It is difficult to establish a ceiling here, but on a parity of the price and the functional the reasonable limit is 350 - 400 thousand.