When installing drywall technology, gaps between the plates are 1-2 mm. According to the norms, it is recommended to seal them not with a gypsum composition, but with a specialized putty for drywall joints.

The mixtures on the market differ in composition depending on the binders. The choice of a particular type depends on the type of work, the characteristics of the premises, the urgency of the repair. The best putties are produced by Russian (Semin, JS Weber Vetonit, Volma) and German manufacturers (Knauf). Among them are high-quality quick-drying compounds that do not require the use of reinforcing tapes.

Types of putty mixtures

Gypsum boards are not decorative material. It requires additional finishing. To do this, you must first conduct a thorough preparation of the base. The edges of the plates are protected with a primer and putty for joints to prevent their destruction. The same materials are used to level drywall surfaces.

Installing sheets without gaps between them is contrary to technology. Due to the loss of linear dimensions of the material under the influence of temperatures, it deforms over time. Therefore, it is important to close the seams carefully. The strength and rigidity of the entire drywall construction depends on their quality. Compliance with all technical requirements for the performance of work and the use of suitable putty guarantees protection against cracks.

Depending on the composition and purpose of the work, you need to choose which putty to seal the seams of drywall. Mixtures differ from each other in characteristics. Compositions produced in Germany, Russia and other countries are presented on the market.

Types of putty depending on the binder

Type | Characteristics |

| Gypsum |

|

| Cement |

|

| Polymer |

|

The most convenient polymer putty for drywall joints in work, it has the widest scope. Such a composition can even be used as a finish. A layer of 1 mm evens out all surface roughness. Cement compositions are suitable for rough work, gypsum - only for interior.

Types of putty depending on the type of work

| Starting (levelling) |

|

| Finishing |

|

| Universal |

|

How to choose

The choice of a specific brand of putty depends on various criteria: price segment, type of work, manufacturer, urgency of repair. Each master proceeds from the specific tasks facing him at the current stage of work.

For primary leveling, it is required to apply a putty for seams with a layer of up to 3 mm. The most obvious choice for the best putty is a dry polymer mix. But this composition has a high price, so it makes no sense to carry out all the alignment steps with it. For rough work, it is wise to purchase a cheaper starter mix.

The final layer is usually applied with a thickness of 1-3 mm. If you use a finishing polymer putty, a layer of 1 mm is enough. To do this, you can buy both a dry mix and a ready-made solution. Masters recommend choosing a mixture in order to knead the solution on their own and be able to control the consistency, not depend on the shelf life of the finished compositions.

Putty for joints from well-known manufacturers

Putties from well-known world manufacturers from Germany (Knauf) and Russia (Semin, JS Weber Vetonit, Volma) are recognized as the best compounds for sealing drywall joints. The best quality is from German Knauf compounds. In order to save on materials, Fugenfüller and Uniflot compositions (more affordable analogues) are often chosen instead of Knauf.

Putty "Knauf Uniflot" for seams

A feature of the professional composition of the German production "Knauf Uniflott" is the possibility of sealing seams and joints without the use of reinforcing tape, with a layer of 1-5 mm. The high-strength mixture of the highest quality is made from pure natural gypsum with polymer additives, environmentally friendly, harmless to health.

In terms of technical characteristics, this putty surpasses all other compounds on the market. It does not crack, does not shrink. Suitable for interior work, especially suitable for sealing long chamfered joints.

"Knauf Fugen"

This is a high-quality and relatively inexpensive gypsum quick-drying putty for walls and joints. The composition is plastic, easy to apply and dries quickly enough after work is completed. Can be applied in two layers 3-5 mm thick. Available in three varieties: universal, "Fugen GV" - for drywall joints, "Fugen Hydro" - moisture resistant.

Semin CE-78

The ready-made mixture "Semin CE-78" of Russian production is designed specifically for sealing drywall joints, roughing and finishing surfaces. Produced on the basis of gypsum, calcium carbonate, resins and chemical additives.

It is easy to use: does not crack, easy to sand, dries quickly. Reliably sticks together any types of the reinforcing tapes. Suitable for coating with various decorative materials.

Due to the quick drying, this putty is used for urgent work. Further construction operations can be carried out after only 2-3 hours after the first application.

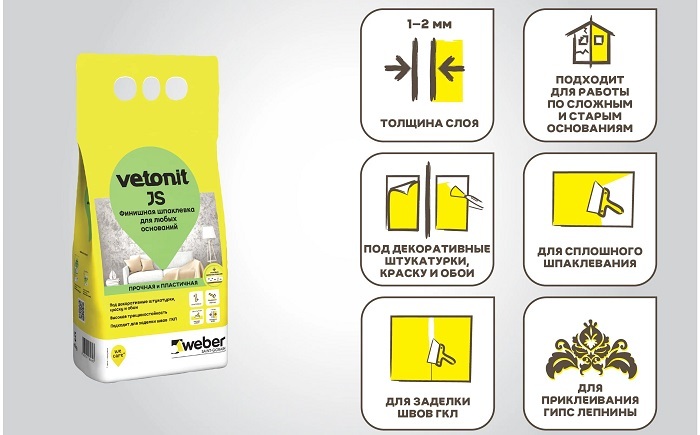

Finishing polymer putty "JS Weber Vetonit"

This is a mixture on a polymeric binder. It contains a reinforcing microfiber that increases strength, has good ductility and adhesion (adhesion to the surface). To improve the properties of putty, the manufacturer recommends replacing 10% of water with Weber when diluting the solution. Vetonit MD16.

When choosing the best way to seal drywall joints, keep in mind that this mixture is designed for interior work in rooms with low humidity: it is not waterproof. With its help, you can create a perfectly flat surface for painting. When sealing the seams, the recesses and edges of adjacent plates are filled with it, then the tape is pressed into the joint with a spatula.

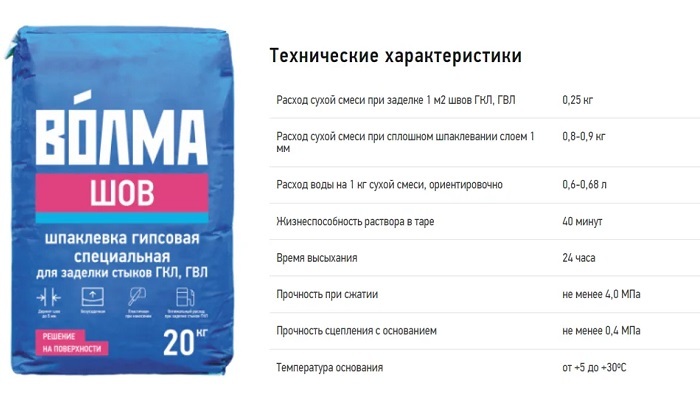

"Volma seam"

This is a special gypsum putty for sealing GCR (gypsum plasterboard sheets) and GVL (gypsum fiber sheets) joints of increased fixation from a Russian manufacturer. It is modified with mineral additives and has good adhesion to treated surfaces. Suitable for sealing joints and eliminating minor defects, irregularities up to 5 mm deep on the surface of drywall. Designed for interior work in rooms with normal humidity, at temperatures from +5 to +30ºС.

The consumption of the mixture is about 0.25 kg when sealing 1m2 of GKL joints. In a container, the solution retains its properties for about 40 minutes. It is easy to apply, quickly wipes off, forming a smooth surface. Full drying time after completion of work - 24 hours.

Seam tools

To achieve absolute smoothness of drywall surfaces, you need to use the right tool. The more professional he is, the faster you can complete the work and be sure of obtaining the expected results.

Necessary materials and tools for sealing joints in drywall:

- putty for plasterboard seams;

- container for diluting the mixture;

- a construction mixer for mixing the mixture or a drill with a mixer attachment;

- reinforcing tape to strengthen the seams;

- flexible metal spatulas:

- narrow (80 mm),

- type-setting (up to 150 mm),

- wide (up to 400 mm);

- mounting knife;

- primer to improve adhesion and protection against moisture penetration;

- rollers, brushes, sprayer for applying a primer composition;

- construction grater and sandpaper for grouting.

When working with putty for sealing joints, you should always use only clean tools. It is recommended to knead the solution in plastic or stainless steel containers.

Preparatory work with joints

Preparation for work begins with the dedusting of all surfaces. Then they check the correct location of the screws: they should be slightly recessed into the drywall, but not damage the surface of the cardboard, and also not rise above it. Under-twisted screws can be pressed a little to the correct position. If they are very recessed, they need to be unscrewed and re-screwed side by side.

Prepare in advance all the necessary materials and tools. Calculate the consumption of putty for the desired area. Pre-coat the prepared surface with a primer with a brush.

After the primer has completely dried, you can start sealing the seams. It is better to knead the putty for walls and joints in parts to prevent it from drying out in the container. The mass ready for work should be homogeneous, without lumps, in consistency like thick sour cream. Now you can proceed to filling the seams with mortar.

Nuances at work

To ensure optimal conditions for work, consider several factors that can affect the final result. Requirements for the conditions of work and its features are as follows:

- No drafts. It is necessary to seal the seams with putty in a room with closed windows and doors. This will prevent the movement of air in the room, leading to the appearance of cracks in the future.

- Temperature above 10 degrees. With colder air in the room, the joint will not be strong, over time it will begin to crumble.

- Reinforcement of seams in new buildings. The building is guaranteed to shrink, without strengthening the seams, drywall slabs will begin to shift and deform.

- Strengthening with fiberglass. To prevent cracks, you can additionally paste over the surface of gypsum boards over the putty with solid fiberglass.

First, prepare the putty solution in accordance with the manufacturer's recommendations indicated on the package. It is best to use a construction mixer or a drill with a nozzle to stir the solution.

When sealing joints, the first layer of plaster is applied to the cleaned, primed joint surface. Then a reinforcing tape is applied and a second layer of leveling compound is applied. After complete drying, the sheets are sanded until a smooth surface is obtained. If after that small flaws remain, then they need to be leveled and re-cleaned.

The controversial question is, can polymer putty be applied to gypsum? In principle, it is possible if the strength of the coating layer composition is higher than the density of the base layer. Experts do not recommend applying a finishing polymer composition over gypsum, as it has a lower pH value, which means lower strength.

Conclusion

The strength and durability of drywall constructions directly depends on the quality of processing and sealing of joints. It is important to choose the right putty composition for each stage of work in accordance with its purpose, characteristics and specific application. Also, before starting work, prepare all the necessary set of tools. Fully comply with the technology of work.

Strictly follow the manufacturer's instructions when preparing putty mortars, apply in several layers and strictly adhere to the time required for complete drying. This gives the plasterboard sheets the required smoothness and eliminates the deformation of the structure due to the appearance of cracks during operation.