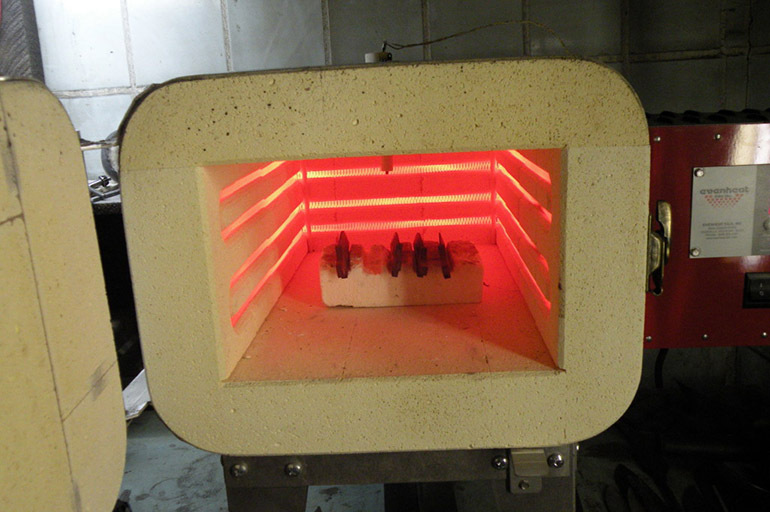

To make a muffle furnace with your own hands, it is not necessary to involve a team of craftsmen. With the help of a home-made structure, it is possible to melt metal blanks, burn ceramics, quickly dry various objects and remove moisture from substances.

You can make a muffle furnace with your own hands.

Content

What is a muffle furnace

Inside the system, various materials can be heated to the desired level. At the same time, unlike other furnaces, the muffle design has a special insulator. It protects the material from the negative effects of combustion products.

With the help of the unit, it is possible to form the required level of heating for melting metal alloys, joining enamels with glass, or firing ceramics.

The presence of the muffle contributes to the uniform heating of workpieces without contact with hot gases. Due to the fact that the workpiece is in an insulated chamber, the heating process takes longer. At the same time, the quality of processing is improved.

The removal of harmful components that appear during the combustion of fuel is carried out by the ventilation system. The furnace installation has a temperature controller that allows you to set the required operating mode.

Purpose

With the help of homemade heating structures, you can:

- Fire ceramics.

- Harden cutting steel objects.

- Melt metals.

The muffle furnace melts metal blanks.

The energy source is either gas or electricity. In this case, it is possible to convert the system for solid fuel or other combustible substances.

Depending on the technical characteristics of the equipment, the oven can be heated from 100 to 2000°C.

Varieties

Units for heating metals are divided into several groups. They differ in the fuel used, power and linear properties, camera placement and other characteristics.

By design

Commercially available ovens are divided into:

- Tubular or cylindrical.

- Horizontal and vertical.

By type of fuel

Electric models are in the greatest demand. They are heated to the desired temperature in a short period of time, and they are also distinguished by safety, subject to the rules of operation.

Electric models are in demand.

This type of furnace supports flexible adjustment of operation and has advanced automation. Electrical units are quite compact and suitable for use in a home workshop or apartment. They can operate on a 220 V mains supply. The key is to keep it grounded.

Gas modifications are distinguished by efficient heating of workpieces, but are inferior to the previous type in terms of safety.

At the same time, to assemble equipment at home, you need to obtain permission from the relevant services.

Coal-fired models are less efficient because it takes a long time to reach the desired heat level. Also, the owners of coal furnaces need to arrange a separate room for the installation of the unit and storage of fuel. The advantage of the devices is the long-term maintenance of the desired temperature and efficiency.

By type of heat treatment

Taking into account the characteristics of the heat-treating substance, furnaces are:

- Air.

- Vacuum.

- Working on inert gas.

By camera location

The furnace tank has a vertical or horizontal placement. The second option is considered more convenient and easier to manufacture. At the same time, it is suitable for firing various materials, including ceramics, metal alloys and glass. Vertical devices have high efficiency and evenly heat the structure, but it is difficult to build them with your own hands.

Horizontal placement of the camera is considered more convenient.

What oven can be made at home

It is easiest to assemble an air oven with your own hands. It can be performed in any convenient form, taking into account the features of the interior and the layout of the house.

Pros of homemade

With the help of a homemade furnace, it is possible to process parts from various materials using nitrogen, chromium or carbon. The presence of muffle insulation excludes the contact of workpieces with components released during operation. This allows processing only with temperature.

In addition, home-made options are much cheaper than store models, and you can assemble them yourself without the help of specialists.

Design and principle of operation

The term "muffle furnace" refers to a closed tank, inside which the desired temperature for heat treatment of metals without interaction with external factors such as combustion products fuel.

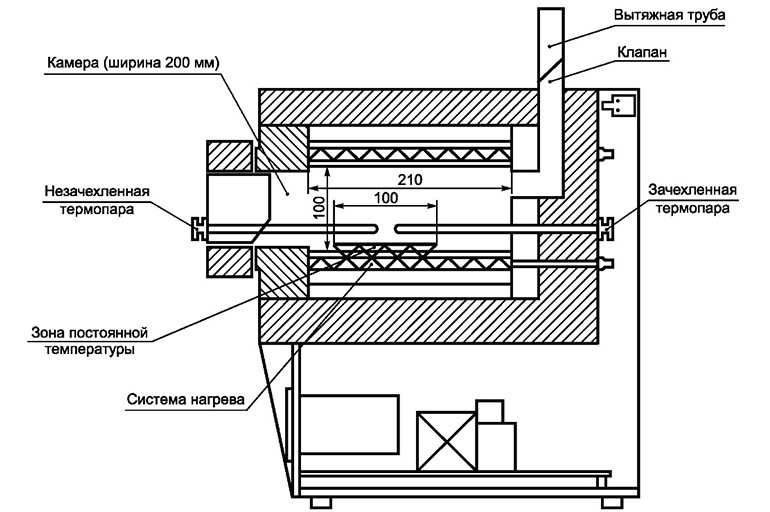

The design of the muffle furnace.

The equipment differs in internal structure. When creating electrical devices, those components are used that will provide the declared heating intensity.

To assemble the chamber, fireclay refractory bricks or ShPGT-450 slabs are used, which withstand peak temperatures and are resistant to acids or alkaline media.

External surfaces are covered with a heat-resistant cloth. In most cases, mineral wool with basalt components is used, since it is inherently resistant to sintering. As a result of reducing heat loss, the efficiency of the device increases. The oven heats up to the desired temperature faster, retains heat longer and consumes less energy from an external source.

To adjust the temperature regime, special regulators are installed in the design. They are:

- Digital.

- Analog.

Disadvantages of a do-it-yourself muffle furnace

Of the negative aspects of structures assembled with one's own hand, one can single out:

- Relatively slow heating. This leads to difficulties in adjusting the operating modes.

- Increased energy consumption. In terms of efficiency, the units are inferior to classic furnace systems without a muffle.

The muffle furnace has a slow heating.

What can be made from

In addition to refractory boards, bricks and metal alloys, a muffle furnace can be made from old, unused items. Among them:

- Clay pot for household needs.

- Steel bucket.

- Oven.

- Electric stove.

To create an effective muffle system from the listed improvised means, you need to show a little imagination and follow the instructions.

How to calculate the power for an electric furnace

The permissible wire thickness depends on the current strength. If you choose a material with an insufficient cross section, it may melt, overheat or burn out during the operation of the furnace.

In the case of nichrome conductors, the permissible current strength depends on the temperature of their heating. For convenient calculation of power, special calculators and tables with recommended parameters for different materials are provided.

How to calculate the surface power of a heating element

To obtain accurate parameters, you need to take into account the diameter and estimated length of the wire. If the results exceed the allowable surface power level, some adjustments to the calculations will be required. With the help of calculators, this process can be simplified as much as possible.

To obtain accurate data, you need to calculate the surface power.

Calculation of the length of the wire for the heating element

It is necessary to specify the total resistance of the heater. After obtaining accurate data on the resistivity of the wire required for assembling the spirals, you can correctly calculate its length.

Creating a drawing of a future furnace

A step-by-step guide to assembling a muffle furnace begins with the preparation of drawings. Designing a scheme for a future structure on your own is quite difficult. Therefore, you can find typical drawings of factory models.

At the same time, it is recommended to make sketches of the structure for convenience in laying layers and connecting heating parts.

Control system

The set of tools responsible for monitoring the operation of equipment includes several devices. They are united in a common scheme and complement each other.

What elements are required

The muffle furnace control system consists of:

- thermostat. It is allowed to install any compatible modifications, such as REX-C100 or Ш-4501.

- Thermocouples. Responsible for the rapid change in temperature inside the isolator and sends the registered information to the temperature controller. In most cases, the thermocouple is located on the back wall of the muffle chamber. A special through hole is allocated under it. For furnaces, a thermocouple with the designation XA, XK or PP is suitable.

- Radiator. The device must have a solid state relay.

- Switches. One element has 2 keys, and the second one has 1.

The furnace control system consists of a thermostat and switches.

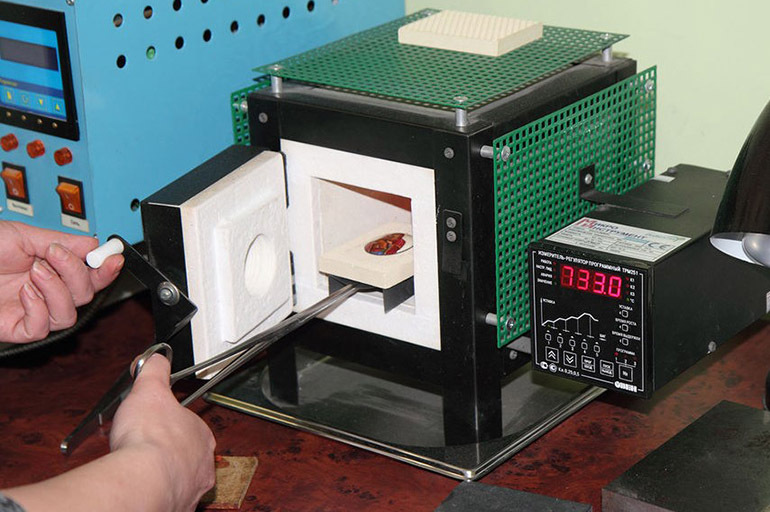

Construction assembly

When manufacturing the control unit, it is necessary to connect a thermostat with an optimal heating level to it. You can take both electronic and mechanical models. Next, connect the thermocouple, solid state relay and switch.

The signal wires from the thermocouple must be connected to the thermostat. If the heating temperature is lower than the set one, it will turn on the power supply to the heater. If the values are exceeded, the system will shut down.

In most cases, switching parts are laid on the back wall, having equipped a special platform (shelf, bracket) for fixing them.

In the absence of skills in working with electronic components, it is better to buy a ready-made block in the store. If the muffle furnace fails, it can be used for other equipment.

Accommodation Requirements

The system should not be installed in small, isolated rooms without ventilation, such as closets or closets. Do not place the stove in rooms where people sleep, eat or spend their leisure time. It is better to allocate a separate room with an open window for the equipment, where you can equip a small firing station.

It is important to consider the allowable distance from the oven to any objects or walls. It is at least 30 cm.

Do not store flammable objects near the muffle installation. This also applies to the material of the walls surrounding the oven. It is better to use concrete or tile.

The requirements for flooring are the same. It must not contain carpets, textiles or parquet.

The muffle furnace is not placed in rooms without ventilation.

Furnace manufacturing

For long and trouble-free operation of the muffle device, it is necessary to design it correctly. It is worth considering general recommendations and drawings.

The choice of material for manufacturing

From the materials for assembly you need to prepare:

- A 2.5 mm thick steel sheet or a case from an old, failed household appliance (gas stove, washing machine, refrigerator).

- Metal pipe or corners.

- Refractory fireclay brick.

- Binder with high temperature resistance.

- Silicone or heat resistant gaskets.

- Automatic stabilizer and thermostat.

- Nichrome wire 1-2 mm thick for assembling the spiral.

- Basalt wool.

- Switching.

Necessary consumables and tools

To process materials, you need to prepare a grinder, a set of metalwork tools and electric arc welding. Of the consumables, you will need a set of electrodes, heat-resistant silicone, nichrome wire, metal corners.

Bulgarian is needed for processing materials.

Step by step instructions for making

The body of the future unit is easy to build from improvised means. You can prepare metal boxes from household appliances. If they are missing, it is better to make a galvanized steel structure.

At the bottom, you need to install corners that will strengthen the base, increasing the margin of safety of the entire system. You can replace them with metal pipes with a cross section of 1.5 cm. Fortified legs must be attached to the corners of the bottom.

In addition, it will be necessary to strengthen the door and wall, as well as the upper part of the case.

The bottom and internal elements must be overlaid with basalt wool with a layer of 1 cm. The material can be fixed with metal corners and covered with sheets.

Refractory bricks of the ShL brand or fiber boards should be laid on the bottom of the unit. The blanks can be connected using chamotte clay, masonry mortar or mortar. For more reliable fixation, 30% cement should be added to the consistency.

Bricklaying will need to be done as close to each other as possible, maintaining a distance of 0.5 cm between each element. The refractory mixture must first be moistened with water. Each element before laying can be additionally moistened.

The first step is to mount the bottom. Next, you should move on to the arrangement of the walls and the upper part, taking into account a slight upward slope. The door can be laid out with bricks so that the laid layer is placed in the opening of the body.

After that, it is necessary to weld the hinges to it, and adjust the door to the dimensions of the gap between the masonry.

After the cement mixture has dried, grooves should be made in the wall material for mounting the nichrome spiral.

The furnace body is constructed from improvised means.

Next, you need to lay 2 circuits to adjust the temperature values. On the front of the oven, you will need to fix a switch with 3 contacts on one side and 2 on the back.

For safe operation of the equipment, it is necessary to install a reinforced socket with earthing. You can also bring power to the device from the shield using a circuit breaker.

It remains to dry the finished oven in the sun or near the heater for 1-2 months.

Health check

Assessing the readiness of the furnace for the first processing is quite simple. It must be connected to the power supply and set the minimum power mode on the spiral. If the unit is in good condition, it will not emit steam.

Steel bucket muffle furnace

A powerful device for melting metal or firing ceramic objects can be made from an old container. The main thing is that the bucket is airtight and has sufficient dimensions to work with blanks.

What materials will be needed

To install the stove from a bucket you need:

- refractory bricks;

- welding installation;

- Bulgarian;

- steel corners to obtain stiffeners.

A muffle furnace can be made from a steel bucket.

In addition, it is necessary to purchase thermal insulation materials, such as asbestos sheets or basalt wool.

Manufacturing process

The body of the future furnace should be cut with a grinder. The height of the bucket should be 45 cm. Further, in the side wall of the container, you need to drill a hole at a distance of 10 cm from the bottom. To do this, you can use a drill with an attached hole saw with a diameter of 2.5 cm. Air or gas will flow through the side openings.

Then the inner surface should be insulated with 5 cm thick mineral wool.

The material should be cut where it covers the hole in the bucket. Then you need to spray a hardener on it and wait a day until the chemical reaction is completed.

Through the hole in the wall it is necessary to pass a steel pipe or nozzle.

It remains to heat the furnace with the selected type of fuel and proceed to melt the metal.

Clay pot muffle furnace for small needs

The simplest version of the stove involves the use of an electric stove, clay pots and a piece of refractory brick. This will quickly melt the material for further processing.

First, you should put a piece of fireclay material on the stove so that the ceramic blank does not come into contact with the spirals on the stove. For thermal insulation of the structure, mineral wool can be used.

At the bottom of the first container, you need to lay asbestos circles with a hole in the center with a diameter of 20 mm. A small pot, which is a muffle, should be wrapped with asbestos in several layers and glued each of them with silicate glue.

After fixing the side layers, you need to wait for the glue to dry for 30 minutes, and then proceed with the assembly of the structure. In order for the edges of the pots to be even, it is recommended to carefully turn the product over and lay it on a flat surface, and then press down with a heavy object from above. In this state, the assembly should be at least 30-60 minutes.

Safety precautions when working with a muffle furnace

Before using the furnace installation, it is necessary to make sure that its elements are in good working order and comply with the regulations. Working with a device with exposed heating parts requires special responsibility. Before firing clay, a trial procedure should be performed. If the segment crumbled, the heating temperature must be increased.

It is forbidden to work with equipment that is not connected to ground. Do not start using the device if there are chips or cracks on the case. It is forbidden to touch the device during operation or touch the moving spiral.

PreviousFireplacesDo-it-yourself fireplace options for a private house