Modern control systems can be considered as a combination of two structural parts or zones: the zone where information is processed, decisions are made and commands are formed, and the zone where these commands. The first is made on complex electronic equipment, often with the use of computer technology. From the point of view of an electrician, this equipment is low-current, turns on rarely and for a long time, starting currents are small. You can turn it on and off with a simple toggle switch or button. And the executive part is powerful electric motors or electric heating devices, which you need to turn on and off with contacts that can withstand high currents. When electrical circuits with high currents are broken, a spark occurs at the break point (between breaking contacts). This phenomenon is dangerous and undesirable, and electricians fight it with the help of various spark-extinguishing devices. Nevertheless, magnetic contact starters are widely used in industry due to the simplicity of their design and reliability of operation.

Read in the article

- 1 The purpose of the magnetic starter

- 2 Device and principle of operation

- 2.1 Standard versions

- 2.2 Reverse modifications

- 3 Varieties

- 3.1 Models of open and protected execution

- 3.2 Dustproof Models

- 4 Installation of magnetic starters

- 5 Connecting the machine to 220 V

- 5.1 Scheme

- 5.2 Step-by-step instruction

- 6 Connecting the device to 380 V

- 6.1 Scheme

- 6.2 Connection guide

- 7 Connecting the device through a push-button post

- 7.1 Scheme

- 7.2 Step-by-step instruction

- 8 Health check

- 9 Conclusion

The purpose of the magnetic starter

Magnetic starters are installed in circuits for automatic, remote and manual control of actuators. They are massively used in circuits for starting and stopping powerful asynchronous motors, reversing them, switching on and off powerful electric heaters, illuminators, etc.

But that's not all. In technology, there is a device very similar to a starter. So similar that even many professionals cannot accurately articulate how they are similar and how they differ. This device is called a "contactor".

In accordance with GOST 30011.4.1-96, a contactor is a device that can turn on, conduct and turn off currents under normal circuit conditions, including operating overloads. And the starter is a combination in one product of all switching devices necessary for starting and stopping the motor, with overload protection. Once again about the same, but in slightly different words. The contactor turns on and off any loads, such as electric furnaces. And the starter works only with electric motors and at the same time monitors their operating modes. The starter provides protection of electric motors against overloads. The starter contains contactors.

In addition, starters are made to work with currents less than contactors. Contactors have baboutLarger spark chambers.

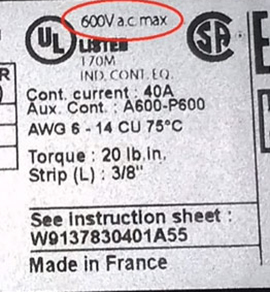

Both contactors and starters close and open contacts in power circuits. These devices are assembled on the basis of an electromagnetic coil with a moving core (armature). They work in DC and AC circuits of different power and different voltages - from 10 to 440 V DC and up to 600 V AC. They include a set of working (power) contacts through which voltage is applied to the connected load. In addition to workers, they have a number of auxiliary contacts on which signal circuits are organized.

Device and principle of operation

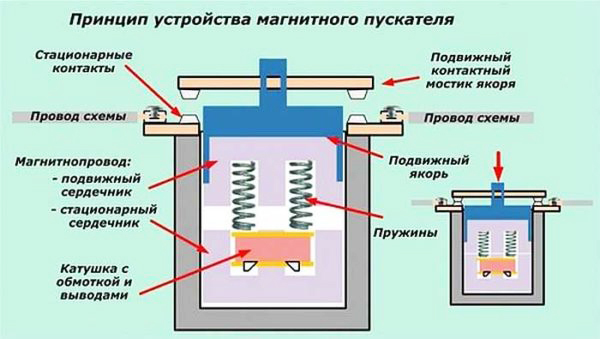

The principle of operation is simple. There is an electromagnetic coil with a movable armature to which electrical contacts are attached. If current is applied to the coil, the resulting magnetic field will draw the armature into the coil, and the armature will pull the contacts attached to it. There will be a new switching of the external electrical network. If the current to the coil is turned off, the spring will return the armature to its original position and the external electrical circuit will restore its configuration. One device has two or three coils (according to the number of motor phases). In combination of closed and open contacts, they form the motor control circuit.

Standard versions

Electromagnetic starters have an alphanumeric designation. According to the standard decoding, you can find out all the features of the starter: series name, starting rated current, the ability to work with reversible electric motors, the degree of protection of the starter itself, the presence of control elements, the number of auxiliary contacts, indications of the macroclimatic region use, etc. Inside the starter housing there are plates with additional useful information. Limit loads, recommended wire cross-section, country of manufacture, reference to standard, certificate information, etc. are indicated.

Reverse modifications

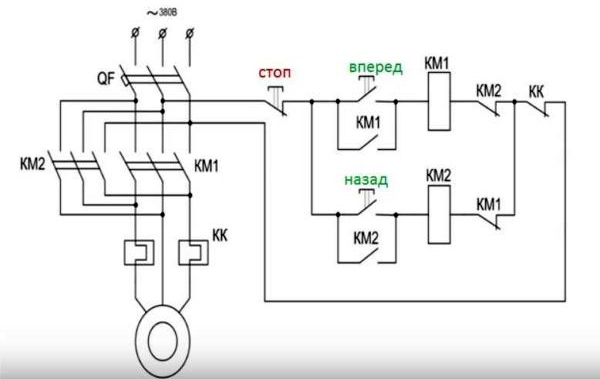

Standard reversing starters are arranged in one housing of two identical starters. To eliminate the possibility of phase-to-phase short circuit, their connection scheme is assembled in such a way that either one starter or the other can work. To accomplish this task, special blocking contacts are used.

Reversing starters are necessarily used in control circuits of reversible asynchronous motors and in many other cases. The motor is reversed when the order of the phases is changed. The blocking subsystem does not allow simultaneous connection of a command in both directions.

Varieties

Starters are manufactured in different designs. This expands the possibilities of using the same functional set in various specific production and climatic conditions.

Models of open and protected execution

Depending on the conditions in which the technological equipment is to work, the designer chooses one or another design from a number of possible ones. The working environment may be very dusty, have high air temperature or humidity, and the location may be subject to strong vibrations. Of course, devices are created taking into account the possibility of falling into such conditions. And the designer must clearly understand the conditions in which he is going to install the device, choose performance corresponding to these conditions and organize all possible protection against negative impacts environment.

Technical means are produced in an open type, with protected elements, in moisture-proof cases. Means of open type are mounted on panels, they may not have cases, they are installed in cabinets and on electrical panels. But there should be no dust in the rooms, especially electrically conductive, as well as excessive humidity. The characteristics of the devices themselves should be as follows: rated current - from 9 Amperes, voltage - up to 380 Volts, number of contacts - 1 or 3, degree of protection of the device - IP20, switching wear resistance - from 2K, medium dimensions - 40 x 80 mm.

Dustproof Models

Electrical equipment by its nature requires protection from moisture, from getting into the circuit of external objects, from the possibility of touching the elements of the circuit. It carries the danger of electric shock if accidentally touched.

Such equipment is classified according to the degree of preventing accidental penetration into the device - this is the degree of IP protection from external influences. In addition, there is a ranking of the climatic version of electrical equipment and a class of protection against electric shock.

Installation of magnetic starters

Error-free operation of electrical equipment can only be ensured with correct and careful installation. The starter must be mounted on a vertical, fixed surface without vibration. The thermal relay must be at a temperature equal to the ambient temperature. There should be no hot equipment nearby. If the ends of the mounting wires are copper, then they are tinned, if they are aluminum, then they are cleaned with a needle file and lubricated with a special paste.

Connecting the machine to 220 V

220 volts is the power that is supplied to the electromagnetic coil from the electrical network. At the same time, any voltage can be applied to the power contacts L1, L2, L3, and it will be possible to remove it when the starter is triggered from the contacts T1, T2 and T3, respectively.

Scheme

Power, in this case 220 V, is supplied to the coil terminals, which are labeled A1 and A2.

Step-by-step instruction

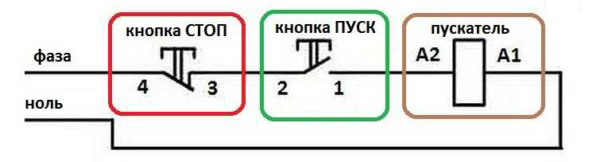

The connection is made according to the usual wiring rules. Installation is carried out with a de-energized circuit. Everything else can be collected in any order. The "Start" and "Stop" buttons are connected in series. To contacts A1 and A2, you need to connect a wire from zero and phase of the source. It can be just a plug to plug into an outlet, or it can be a power switch.

After that, you can check the correct installation to this position: connect the power supply and sequentially press the "Start" and "Stop" buttons. If the starter coil responds correctly to these actions, it is necessary to de-energize the device and install the power part of the circuit. You can then power up the starter and load again and perform a full test.

Connecting the device to 380 V

The installation rules remain the same, it’s just that the circuit will receive the supply voltage not from zero and phase, but from any two phases.

Scheme

The starter coils are powered through buttons from any two phases. The load is powered by three phases. If the engine spins in the wrong direction when the Start button is pressed, you need to swap the wires going to the engine from any two phases.

Connection guide

The main document that must be followed when carrying out any work with electrical equipment is PUE-7 (Electrical Installation Rules - Seventh Edition).

Connecting the device through a push-button post

To control the electric motor, you can install autonomous buttons with the "Start" and "Stop" functions, or you can use a structurally complete unit called "Button Station". If the electric motor or any other load is a component of an automated control system (ACS), then you should organize the possibility of choosing several modes: automatic (A), remote (D), manual (R). In mode A, the engine turns on / off the system, in mode D, control is performed by buttons “Forward” / “Back”, in P mode, the operator-technologist approaches the actuator and twists his hands steering wheel.

Scheme

The connection diagrams of individual buttons and a push-button post in the electrical part are completely identical. It's just that during installation work on real products, you need to find the necessary contacts and terminals.

Step-by-step instruction

The installation rules are no different from the rules for working with other elements of the system. It can be noted that buttons, push-button posts can be mounted on the control panel, the main switchboard panel, can be built into the mnemonic diagram.

If the devices are rigidly fixed on the shield, then the installation can be carried out with a single-core wire. The main thing is to make sure that when removing the insulation from it, do not accidentally cut the wire itself and do not bend it once again, otherwise it will break.

All installation work must be carried out with the power off. After each subsequent installation operation, it is necessary to check with a tester that the electrical circuit is formed and there is no short circuit.

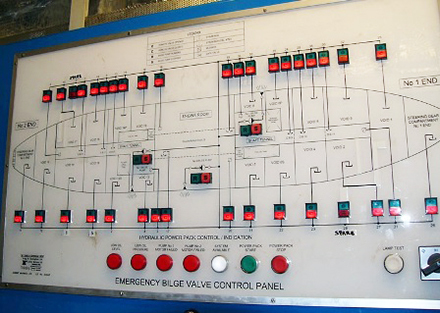

On modern control systems for electrical equipment, control equipment and controls are often placed on large control panels with an active mnemonic circuit. This is a visual representation of a complex of equipment with an indication of technological units and connections between them. Control devices are built into the mnemonic diagram, indicating the fact that the units are turned on or off. Keys for selecting control modes and remote control buttons are built in nearby.

Such solutions were advanced in the last century. At present, active mimics are executed on computer screens, and real buttons give way to virtual ones. But the starter is still real.

Health check

Before installation in a regular place, all electrical equipment should be checked for operability on test benches. Such a check will save you from unexpected troubles during tests in the workplace.

After completing the installation of each functional component of the circuit, it should be checked for the passage of the command and its acceptance, as well as for the absence of false connections. If everything that was conceived works correctly, the work can be considered completed.

Conclusion

Magnetic starters are essential components of any control system. They participate in the execution of the decision made by the control system headed by the human operator. The correct choice of starter and its correct application is the key to the success of all work.

I've been looking at buying a sauna for a long time. I recently found exactly that one at an exhibition in Zyablikovo ...

A friend designed a garage for me. It remains only to find a team for implementation. Well on…

Guys, it's not complete. You don't mention Domorost, but still these guys have a problem...

Hello, thank you for the informative information. Health to you and your loved ones. Sk…

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...