Shed roofs have an ambiguous assessment from consumers. Someone, mostly pragmatists, like pitched roofs for their structural simplicity, low weight, good maintainability, low windage and a number of other advantages. To others, aesthetes, they seem artistically primitive and forced to make a sloping ceiling, but they seem to be poorly holding the snow load. As a result, it turns out that the vast majority of shed roofs cover outbuildings: sheds, baths, etc. And making a shed roof for a garage with your own hands is not at all difficult.

Read in the article

- 1 Features of shed roofs for a garage

- 2 Varieties

- 2.1 Ventilated

- 2.2 Non-ventilated

- 3 Shed roof device

- 4 Advantages and disadvantages

- 5 How to make a shed roof for a garage with your own hands

- 5.1 Parameter calculation

- 5.2 Create a project

- 5.3 Tools and materials

- 5.4 Mauerlat equipment

- 5.5 Installation of beams

- 5.6 Rafter fastening

- 5.7 Attaching the crate

- 5.8 Roofing on frame

- 5.9 Internal waterproofing device

- 5.10 Installation of thermal insulation

- 6 Photo examples of garages with a pitched roof

- 7 Conclusion

Features of shed roofs for a garage

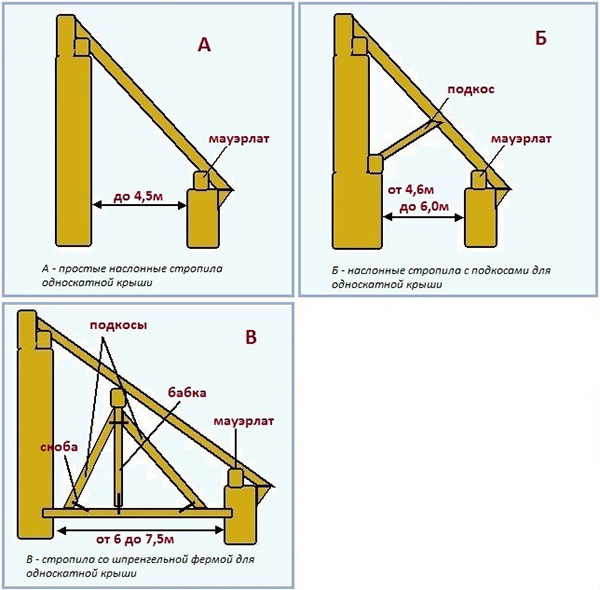

Some features of a shed garage roof can be noted, which distinguish it from the roofs of ordinary country houses. Its design is extremely simple and is determined by the width. There is also a limit on the maximum height of solid rafters - no higher than 4.5 m.

Parts of the composite rafters are joined on the rack. Their length can reach up to 12 m, the cross section of the rafters is 30 x 150 mm. The rafters are laid in increments of approximately 80 cm.

The design of the truss frame determines the distance between the supporting walls. A shed roof must necessarily have overhangs, they are taken into account when calculating the roof area.

Varieties

There are many varieties of pitched roofs. They differ in the steepness of the slope, the design of the rafters, the size, the type of roof and other features.

Ventilated

The name itself already speaks of the scope of this type of roofing. The slope of such a roof is in the range of 3-6 degrees. The pediments are freely blown by the wind, no insulation is provided. In the roof between the layers of waterproofing and insulation there is a space in which the air flow is circulated. Air enters here through special openings in the supporting walls. This is how summer gazebos and terraces are built, but this option is not recommended for a garage.

Non-ventilated

The slope of the roof of a non-ventilated type is made up to 25 degrees. It depends on the material of the roof. Such a roof is made on solid buildings that are operated all year round: serious garages, residential buildings, heated warehouses. Roofs of this type are carefully insulated and sealed to reduce heat loss.

Shed roof device

At the heart of the design of a shed roof is a truss system. Beam-rafters with their ends lie on opposite walls of different heights. The walls are immediately built as a single structure, without superstructures. So, the construction technology is simplified, and the wall is more reliable. The height difference gives the slope the slope at which spontaneous snow slides off the roof. The slope of the rafters is pre-designed in accordance with the design features of the structure.

Advantages and disadvantages

A shed roof has a number of advantages and, of course, some disadvantages.

A shed roof will require fewer building materials, which gives significant financial savings. Such a roof has a simpler design and, as a result, easier and cheaper installation. It is lighter than a gable in weight, and the walls do not need to increase strength. One slope resists wind and snow loads well. And the roof can be built with a different angle of inclination. Craftsmen manage to install a water-heating tank or solar panels on a slope and arrange a place to relax. The roof can be covered with almost any roofing material.

But a shed roof has its drawbacks. It needs to be more seriously insulated than a gable, since there is too thin an air layer under it. A small slope of the slope deprives the house of both an air heat insulator and an attic space.

How to make a shed roof for a garage with your own hands

If the owner of the garage has skillful hands, then he can make a shed roof on his own.

Parameter calculation

Initially, the building dimensions of the future garage are set (width, length and height), then the orientation of the roof slope and location rafter beams (along or across the slope), as well as the technical characteristics of the proposed building materials.

The main structural element of a shed roof is a rafter or rafter leg. The beam bends under load. It must be tested for strength under prolonged exposure to such a bending force. The maximum possible force itself is known - this is the maximum snow load, taking into account the safety factor for emergency circumstances. The load consists of the weight of the roofing, the weight of the continuous lathing used for arranging slopes up to 25 °, the weight insulation, if it is planned to be installed, and the mass of snow cover, established by long-term observations in this region.

The sag is determined for the span width (the distance between the two supports on which the beam rests) and the cross section of the beam. The calculation is carried out according to the rules of the science "resistance of materials", known to all engineers under the name "sopromat".

To facilitate the task for non-specialists, specialized online calculators have been developed and are available on the Internet. At the entrance to the program, it is required to enter several quantities known to the builder, and at the exit - to get the result: required beam section, allowable span, sag, cross section required by strength conditions beams. Based on the results obtained, the builder himself decides what to do next: take a thicker beam, make a smaller span, or put a vertical support under the middle of the rafter leg.

Create a project

Optimally, the interior space of the garage for one car has dimensions of 3.5 × 5.2 m. If the roof slope is laid from one long wall to another, then the beams are short, and they can be safely laid on the walls. In another version, the rafters are obtained more than five meters, and they need to be strengthened with supporting struts. When designing a roof, eaves and gable overhangs should be provided.

The project should include drawings of a general view of the garage frame, the layout of the rafter legs, drawings truss units, their detailing, explanatory note, specification and calculation of the cost of the roof with materials and installation works.

Tools and materials

To work on the creation of the roof, the master will need a set of carpentry tools and a set of roofers. Carpentry - ordinary: a hacksaw for wood, a planer, a hammer, a nail puller, a drill with drills. You will need different fasteners: screws and nails of different sizes.

The materials needed are those from which the roof will be built, i.e. boards of different sections. Roofing material can be any of the commercially available: ceramic tiles, ondulin, slate, corrugated board, roofing felt, polycarbonate, etc. The master should choose according to his criteria of price and quality.

Mauerlat equipment

Mauerlat is an important structural element that connects the roof to the frame of the house. The roof itself is a heavy structure, and the Mauerlat distributes its weight evenly around the entire perimeter of the frame. This element creates an even horizontal support for the truss system.

The Mauerlat itself for the roof of the garage can be made from a beam with a section of 100 x 150 mm. For wooden rafters, you need a wooden mauerlat made of high quality wood. Before assembly, it should be impregnated with moisture-resistant and antiseptic compounds, it can be smeared with tar.

It is necessary to assemble the Mauerlat from solid, non-jointed beams. Under the assembled frame it is necessary to lay 2-3 layers of roofing material. It can be fixed only on those walls on which the ends of the rafter legs rest.

Installation of beams

Builders have a proven technology for installing truss beams. Its purpose is to create an even, without distortion, surface on which the roof is laid.

First, two extreme rafter legs are pulled up. Their installation is tried on, the necessary selections are made in the right places on the beams and Mauerlat and their trial temporary fastening in place. Then they are lowered down and the necessary refinement is repeated on the other beams according to the model. It is more convenient and safer to carry out these works below. By the way, the beams on the rafters must be sawn off with a small margin.

Rafter fastening

Fastening rafters is not an easy, but rather interesting engineering solution, although it was invented many decades ago. The rafter legs are attached to the main building structure of the house using a wooden transition piece. In some cases, this function is performed by the Mauerlat. It is the top frame of the structure.

Wooden parts have one amazing and not always pleasant feature for builders - in wet weather, the pieces of wood become damp. And when damp, they change their size. But each wooden detail in the overall construction of the house is joined to other details, also wooden. And they also become damp and change their size. And since different parts can be made from different types of wood, they will change their dimensions differently from the same dampness. And the whole structure is skewed.

Therefore, builders have to solve three important tasks:

- parts that change their dimensions must be able to move one relative to the other;

- the connection must not be broken;

- after the cause of the violation has been eliminated, the connection must remain strong.

And the solution was found. At the end of the rafter, a cut (or cutting) is made in the form of a triangle with a tooth. The area of \u200b\u200bsupport for the rafters on the support beam (Mauerlat or strapping) increases. The connection of two important elements of the structure will always, after any movement, remain correct. Such a connection allows the rafter leg to turn slightly under the influence of the load and move slightly without destroying the connection.

Attaching the crate

The next stage of work is the device of the crate on top of the rafters. It is created for the organization of roofing.

The crate in conjunction with the rafters resembles a lattice. The thickness and width of the boards depend on the width, weight and length of the sheets of roofing material. The lathing can be ordinary, sparse or solid, single-layer or two-layer (the choice depends on the size and rigidity of the roofing sheets), it is nailed to each rafter.

Roofing on frame

Lathing bars should not damage the soft roofing material, so their edges should be slightly rounded. The joints of the two laths of the crate should not be located side by side on the same rafter, they must be carried along different beams. And the joints of unedged boards and the long ends of the roof overhangs should be sheathed with roofing iron with a collar.

Internal waterproofing device

The waterproofing film is laid over the beams and fastened with a stapler.

Installation of thermal insulation

Immediately after the installation of the crate, a layer of insulation is laid, if such is designed. And if the thermal insulation is made in a thick layer, in this case the crate is made double.

Photo examples of garages with a pitched roof

Each car owner builds a garage for himself and to his liking. This one built a garage with a shed roof to the wall of the main house.

And this one did not become wiser and built an extremely simple garage.

Another partnered up with friendly neighbors to build a three-car garage.

And here is the garage for cars of different sizes.

When there is not enough free space on the site, you have to unite with your barn.

Conclusion

Today, a summer resident without a car is a rarity. And it is not always possible to get there by train, and the harvest must be taken away in the fall. Well, small children with elderly parents can only be taken by car. And, of course, how is a car without a home? So they build cheaper garages in summer cottages, sometimes they are thrown off for three.

From strong winds, fences sometimes fall if they are installed unreliably. We have our own at Terem-p ...

We bought a summer cottage with a dilapidated country house. They restored it through the tower. AND …

The tm film and the zebra have nothing to do with PLEN, do not mislead people ...

We need this Vodonaeva with her cats like fifth leg dogs.

I need to make a Christmas tree out of cardboard for the office. If you do this please give me a call...

Don't chase the blizzard... In your opinion, all the great writers were prostitutes. Go...

Hello! And how can you make a cone planter for flowers, or rather, how to fasten the cone?

Four days ago I ordered a Revolts heating kit for our dacha. I'm going to pick up tomorrow...

If the apartment is ready, then why doesn’t Buzova broadcast to the whole world about moving and living ...

Like 10m. Enough tape for 1.5m of fence?!

This is most likely an Internet modem like yota. And, I remember, they used both polarizers ...

Wicker fence is a waste of time and money. When we were equipping the site, we bought: up to ...

6 acres is a fairly small area, so there were no problems with zoning ...