The idea of a self-contained home excites the minds of many owners country cottages. And this is not surprising: utilities rise in price twice a year, but meanwhile - here it is, water under your feet, thermal heat and solar energy. Nature itself gives us everything we need, so why not take advantage of its gifts? Take, for example, the energy of our cosmic body. These are literally free kilowatts that you can get if you make solar panels with your own hands. You can buy, of course, but self-production is significant savings. So, let's figure out how to make a power plant for the home.

Read in the article

- 1 How solar panels are arranged and work

- 2 Types of photocells and their features

- 3 What materials are required to create solar panels

- 4 Solar battery from design to inclusion

- 4.1 advance planning

- 4.2 How to assemble photocells into a single complex

- 5 Where is the best place to put a solar panel

How solar panels are arranged and work

If you are familiar with the school physics course, then you probably know such a term as semiconductors. It is on them that the work of solar panels is built. Homo sapiens discovered silicon, and today it is the most perfect semiconductor known. When the top silicon wafer of a semiconductor heats up, the electrons at the top move to the bottom wafer, but are pulled back to their rightful place. They find their way through the connecting wires and give energy to the batteries along the way. In general, the whole secret is in moving electrons and in directing them in the right direction.

How is a solar battery arranged? These are, in fact, the silicon panels themselves, electron energy conversion systems, batteries for saving this energy and additional elements that allow you to extract this energy for the benefit of the owner. Blocks of converters, they are also photocells, they are also silicon panels - these are semiconductors. Silicon can be deposited by the single-crystal method, which has already been mentioned, or by the polycrystalline method, which is less efficient in operation.

To save energy, you will need batteries, and there should be two of them (the second acts as a backup). The first battery collects and sends energy directly to consumption devices, and the second is needed in order to store the excess of this energy. As soon as the voltage in the network starts to drop, the reserve is connected.

When self-assembling a solar panel complex, you can not neglect any elements. Each of them, even the smallest, performs an important task. Here, for example, diodes. It would seem that they are not so needed, but in fact they perform the responsible task of protecting blocks from overheating.

Types of photocells and their features

silicon panels for solar panels are polycrystalline and monocrystalline. Let's figure out what are their differences and which are the most effective:

- Monocrystalline cells are more expensive than their counterparts, since their manufacture requires the use of the most advanced technologies. Such plates have an efficiency of up to 25% and can work for at least a quarter of a century. This is a very decent time for such elements. At the same time, in 25 years they will lose only about 5% of their effectiveness, which is not significant. Monocrystalline panels capture solar energy over the entire surface and continue to work even in cloudy weather. In fact, although these batteries are more expensive, they pay for themselves much faster than polycrystalline ones. In addition, they are required in smaller quantities, that is, for getting a certain amount of electricity you can take up less space with monocrystalline silicon solar cells.

- Polycrystalline batteries are inferior to monocrystalline ones, if only because they use lower quality silicon. The manufacturing process is more primitive, and this directly affects the effectiveness of the finished product. Often, polycrystalline batteries are simply made from monocrystalline waste products. They have a bluish tint, they are easy to distinguish. Polycrystalline cells are 20% less efficient, and the efficiency does not rise above 18%. It turns out that a large area is required to extract the required amount of energy. But, despite the obviously low efficiency, polycrystalline solar cells are bought more often. And it's not just the price. They show excellent results in cloudy weather - better than single crystals.

film batteries - a novelty in the market of photocells, which is only gaining popularity so far. The cost of these panels is still too high for mass demand, but you should pay attention to them for several reasons:

- Film elements based on cadmium telluride are space technologies that have been successfully tested on extraterrestrial vehicles. A small nuance is still present - when heated, cadmium emits toxic fumes. In solar panels, they are minimal and practically safe outdoors.

- But CIGS-based elements are another matter. They are safe as they consist of copper, selenium, indium and gallium. The advantage of this type is excellent flexibility. And, by the way, this type was also actively used on space satellites, and now it has become mega-popular among consumers of products for active tourism. The efficiency of small CIGS solar power supplies reaches 20%.

Another type of solar storage amorphous batteries. They are also based on silicon, but it is applied by a special method of hot steam spraying, which eliminates the growth of crystals and significantly speeds up the process. The most modern amorphous modules show an efficiency of 12%, but so far they are not so popular due to their high cost. Amorphous modules have a significant advantage over all the others - they are able to work even under extreme heat and ambient lighting.

Analyzing the types of solar cells, we can conclude that today the most optimal choice would be single-crystal solar cells.

What materials are required to create solar panels

For solar panel assembly you will need, in addition to photocells, chipboard sheets or OSB, aluminum corners and rails, high rigidity foam sheet, silicone-based sealant, terminals, transistor, diodes and wires.

To work, you need a minimum set of tools: a soldering iron, screwdrivers (preferably a screwdriver with nozzles), hacksaws for metal and wood. To check the efficiency of the battery, you will need a tester.

Module panels are assembled using an aluminum profile. It is unwise to purchase batteries of different sizes - this will make it difficult for you to put everything together. In addition, such an assembly option will adversely affect the efficiency of the complex, since the maximum generated current will be limited by the performance of the smallest modules.

For the frame, you can use not only aluminum rails, but also wood. However, aluminum is preferred for several reasons: it is not afraid of corrosion, insects, rot and fungus. It does not absorb water like wood and does not deform after rain or snowfall. And most importantly, aluminum is light and strong - just what you need for the frame. The base is best OSB: these panels are also not afraid of dampness, especially if they are pre-painted with any waterproof enamel.

It is important to choose the right protective glass for solar panels. There are several options: ordinary glass, plexiglass, plexiglass or polycarbonate. All these are cheap options that do not provide good transparency and thus reduce the efficiency of photovoltaic cells. If possible, choose anti-reflective glass - this will be the best option. No possibility - then ordinary glass, which is used for windows.

Sealant is needed to fix the photocells on the glass. An epoxy compound is considered the most reliable option, but this is an expensive tool, so many people replace it with a silicone counterpart.

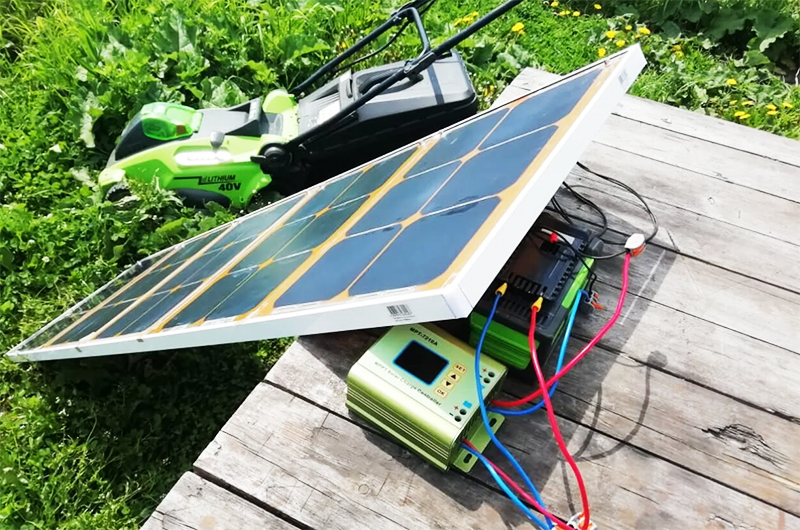

As for batteries, there is only one piece of advice: do not skimp on a quality device. A good battery will last much longer and show itself worthy in work. To connect solar panels as a power source, you will need a 220 volt converter or, as it is also called, an inverter.

And now about how to make solar panels at home.

Solar battery from design to inclusion

Before proceeding with the assembly of the solar battery, you need to at least minimally sketch out a diagram of the future devices, only then will you know how to independently assemble a workable module from modules panel.

advance planning

How to do it yourself? First of all, decide on the location of the future structure. The surest step is to make the complex in such a way that you can adjust its slope so that batteries "followed" the sun at different times of the day and even depending on seasonal location luminaries.

This solution will double the rated power of the complex. If you have made a choice in favor of stationary frames, they need to be placed at an inclination of 50-60 degrees. But the movable frames require a slope of 70 degrees in winter and 30 degrees in summer.

The second essential point in planning is the determination of the number of photocells. To do this, you need to know the amount of energy generated from one plate and your need. For example: a photocell with an area of 1 square meter generates about 125 watts. To get energy for the needs of a small house, a minimum of 2.5 kW is required. So consider how many panels you need, and think about where and how to place them.

How to assemble photocells into a single complex

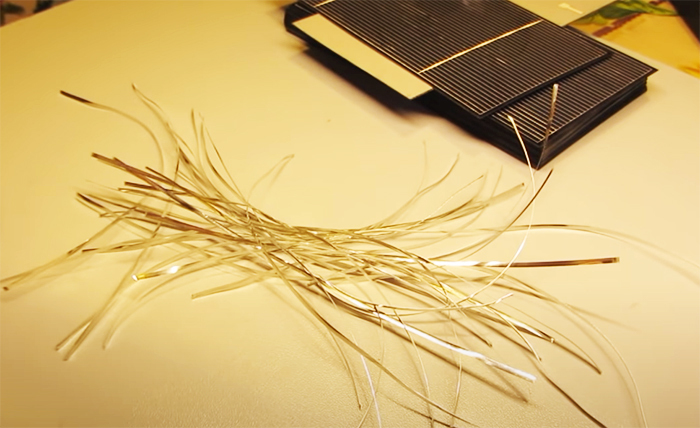

Photomodules need to be combined into a common complex. To do this, the contacts of each element are soldered to the conductor wires. How to do it right:

- all the modules that you will connect are laid out on a flat area (table, glass);

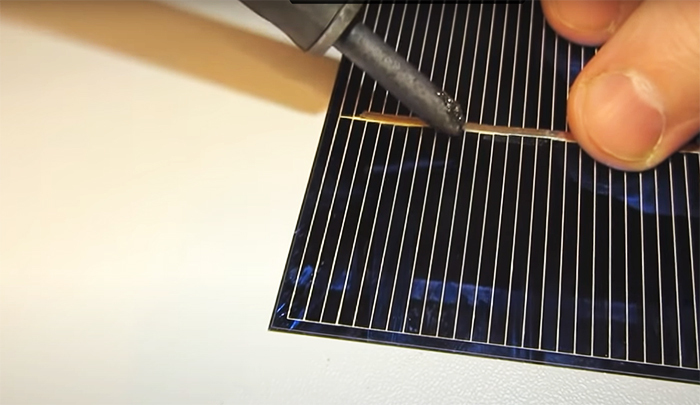

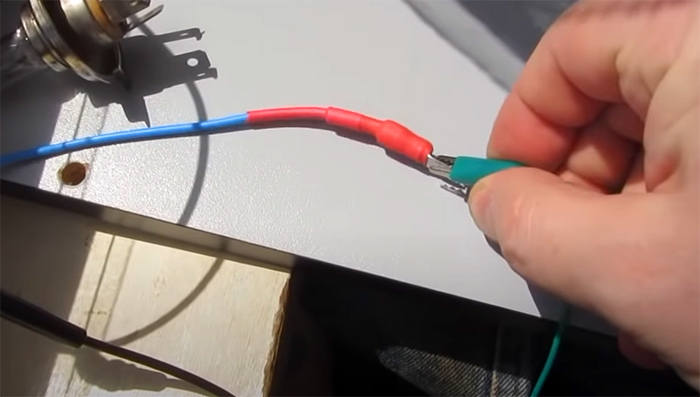

- how to solder: conductors are applied to the contacts. This must be done very carefully so as not to damage the fragile plates;

- some models of conductors are already sold with connecting wires. This makes the task much easier, so if you have a choice, take these;

- it remains only to measure the total current from the resulting complex.

The next step is to make a frame for the battery. In fact, this is a box in which there is a bottom made of OSB or plywood, low sides and a top cover - transparent glass.

Prepare OSB or plywood large enough to fit all the photocells. At its base, several holes are made for ventilation. Sides are attached around the perimeter - these can be wooden or aluminum slats. The height of the rails is 1.5–2 cm, no more, otherwise they will cast a shadow on the photocells.

Next, the solar cells are placed face to the glass. A distance of approximately 5 mm is left between the modules. To make everything turn out perfectly even, you can pre-mark the glass.

Then, respectively, the positive contacts are connected to the positive ones, the minuses to the minuses. Plus is placed from the front edge, minus - from the inside.

The modules are connected from top to bottom so that you do not inadvertently damage foil-thin elements during connection. All vertical rows are soldered to a common bus.

Each module is glued to the glass with a sealant. This must be done carefully, because it will be impossible to fix it later without destroying the photocell. Sealant is applied in a small amount directly to the center of each photocell.

All wires are fixed with sealant, after which you can assemble the frame. Previously, foam rubber is laid at the bottom of the box, which will act as a damper.

Where is the best place to put a solar panel

For the installation of a solar complex, places not shaded by tree crowns are suitable. If you have several modules, they need to be placed so that they do not cast shadows on each other.

For maximum efficiency, the modules should be located perpendicular to the sun's rays.

In addition, a useful video on assembling from improvised materials and installing solar panels:

Would you like to use an alternative power source? Or do you already have solar power in your home? Share your experience in the comments!

Hello, my name is Andrey. I am buying information sites. There is…

and if the top layer of foam is not broken, then the lacquer surface greatly reduces the hygroscopic ...

strange reasoning regarding sealing. If the log is doused with sealant, foam ...

In the 80s he worked in one NPO, then hammer enamel was sintered. It turned out great,...

While in the summer I lived in the country a lot of different situations I saw and no one fines anyone. Uch…

You won't find a normal apartment for such a sum in Moscow. Even for a country house that …

Thank you. Briefly and clearly...

Karting. I want to help children! &nbs …

Now there is a very interesting and effective option for heating - plasterboard pas …

Everything is chic, but the emphasis is always on the ratchet. And for me, for example, it is technologically not p ...

yes indeed. you won’t call them later for the whole year no one appeared, they began to hear ...

And why sheathe the house initially with vapor barrier? What is its meaning? To create a conden…