People are already accustomed to the fact that the holes are drilled with a drill, and the drills are round, therefore, holes (in everyday language - "holes") can only be round. And in life, holes are needed of different shapes, and a skilled craftsman, with the appropriate tools, can make them. You just need to know how to drill a square hole.

Read in the article

- 1 Methods for making square holes

- 2 Drill Watts

- 3 Conclusion

Methods for making square holes

There are many ways to make a square hole. The choice of method depends on the material in which the hole needs to be made, its thickness, the required accuracy, the availability of tools and devices, the skills and abilities of the master.

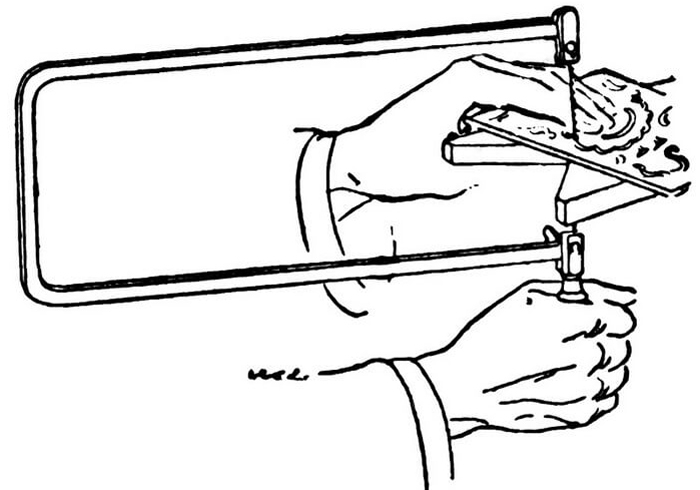

The easiest way to make a square hole in the plywood is to use a jigsaw. A square or any required shape is drawn in the right place. Then a hole is made inside the contour of the square with an awl or a thin drill, a file is inserted into it, the jigsaw is assembled - and the sawing process begins. Of course, it will not hurt to have the skills to work with a jigsaw.

In a tin or thin sheet aluminum, the square can be cut with small metal scissors with short blades. Only first, inside the contour of the square, you need to pierce a hole, insert the sharp end of the blade there and carefully cut along the contour. Then, with a hammer, align the plane of the part along the edges of the square.

If the aluminum is thicker than 1 mm, the hole can be cut with a chisel. Then straighten the edges of the contour with a hammer and carefully process with a small file. Punching can also be done on a lathe. A punching press, equipped with dies and dies, develops a force sufficient to punch a hole in a part several millimeters thick.

If the material is thick, then you will have to use the drilling method. And in this case, there will be several options, differing in the complexity of the technology and the tools used. Ordinary round drills can be used. The required square is drawn on the workpiece, while a margin for finishing should be provided. The thinnest ones drill holes in the corners of the planned square. Then you need to take a drill of a slightly larger diameter, draw a square, retreating half the diameter of the drill into the main square. Along this new contour, mark the marks with a step equal to the diameter of the new drill, and drill the workpiece along these marks. It is easy to cut the jumpers between the holes with a chisel, the middle will fall out. Now the contour of the resulting hole should be filed.

Very precise shape and dimensions can be obtained by laser cutting. The source of a thin laser beam with high energy is attached to the movable head of the coordinate machine. The head trajectory is determined by a pre-written program. Cutting out a square is one of the simplest tasks, it is possible to cut through the most complex lace patterns. Almost any material can be cut with a laser beam - plywood, plastic, sheet metal. On thick metal, you can draw any patterns with a ray.

It is possible to make a square or even a versatile hole with right angles in the part with ordinary round drills. To do this, by marking the future hole, you need to drill the corners with a thin drill, stepping back a little from the edges of the figure, drill the contour and select the metal from the middle of the contour with a larger drill. Then process the edges and corners of the figure with a flat file.

Drill Watts

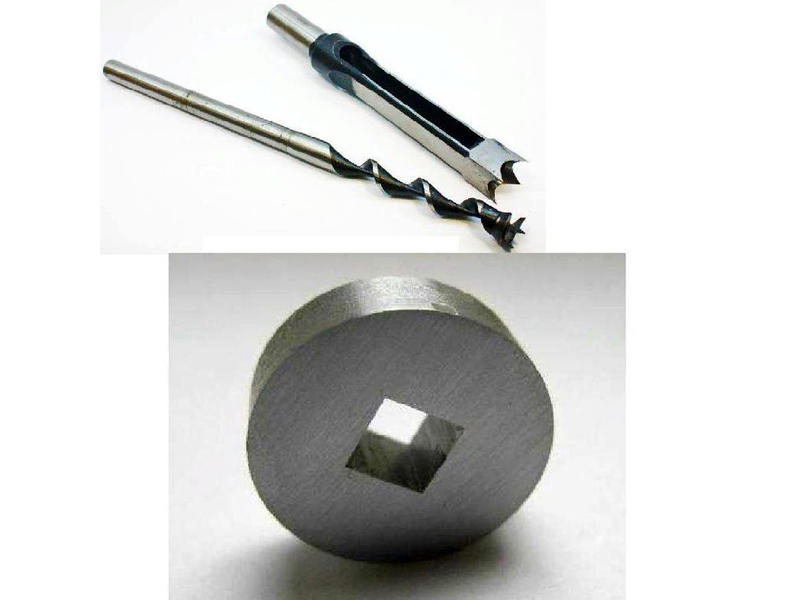

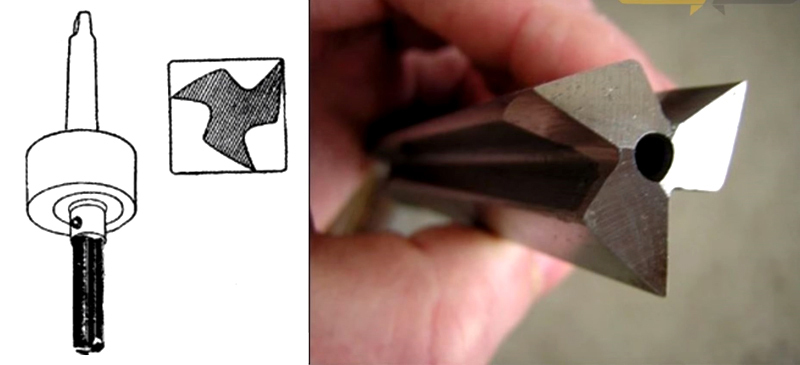

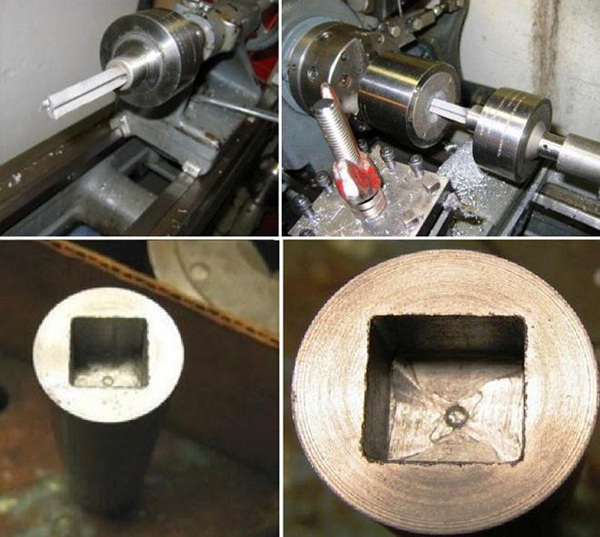

There is a way to drill a square hole on a drilling machine equipped with a special device. The method is based on the use of a Watts drill, the shape of which in section corresponds to the Reuleaux triangle.

If this cunning triangle is rotated around its center, and the center moves along its circular path, then the vertices of the triangle will draw almost a square when moving. Only the corners will be slightly rounded. They need to be filed. The Watts drill can be mounted on a lathe and drilled square holes in parts of any thickness. It is only necessary to install special devices between the chuck of the machine and the drill.

Conclusion

A quick-witted master with skillful hands will always find a way out of any hopeless situation. You need to have a good feel for the material, understand the capabilities of the instrument and think over the sequence of operations. Ancient craftsmen did not have machines similar to modern ones, did not own such a range of tools, as now, and all the same they made products and mechanisms that cause surprise and admiration in our time.

In general, I support it, only concrete does not lose its properties after wintering, especially if you w ...

They took a heating kit Revolts into the bathroom. When there was no heating in the interseason ...

I bought a set of plasterboard heating revolts - for additional heating to ...

Hello! I want to put two glass houses at the recreation center. You can contact ...

Nice to watch you work. I would like to invite you to me, eh. T O I have rosettes ...

I ordered a set of heating revolts for the loggia a month ago. A week ago, everything was installed ...

I have one apartment - I rented it out, and in the spring I bought another one in Kazako ...

He was once a good journalist. But... he got sick and became a propagandist! Maybe not so ...

Thanks for the interesting article! I opted for Decorazza. Elegant silk effect ...

I have Londix Effect tablets, they are not in the author's list, but in vain. The pills are cool, not p ...