For a long time, blacksmithing has been one of the most demanded skills, the secrets of which lend themselves only to a few. It is difficult even to imagine how the blacksmiths of antiquity coped with such a time-consuming process. Needless to say, even now not everyone has the opportunity to place a full-fledged smithy with all the appropriate equipment in a private house (and even more so an apartment). But do not forget that this is the 21st century. Technology still makes it easier to work with metal. One of the clearest examples of progress in this direction are cold forging machines. These, at first glance, unusual devices have a fairly wide range of applications, not limited only to the field of construction and mechanical engineering. Who needs such a device, what are its capabilities, strengths and weaknesses of the equipment? Our new article from HouseChief is dedicated to the answers to these questions! Take a few minutes of your time and you will discover a new element of the vast world of blacksmithing.

Read in the article

- 1 Functionality and scope of cold forging machines

- 2 Types of equipment: what are the machines for cold forging

- 2.1 Gnutik

- 2.2 Wave

- 2.3 Snail

- 2.4 Twister

- 2.5 the globe

- 2.6 Universal model

- 3 How to choose the right machine for cold forging: the main selection criteria

- 3.1 Method of work (control)

- 3.2 Equipment manufacturer

- 3.3 Multitasking

- 3.4 The cost of the apparatus

- 4 Features of the operation of machines for cold forging

- 5 conclusions

Functionality and scope of cold forging machines

First, let's define the capabilities of the products and the scope of their application. As you might guess, any representative of this category is intended, first of all, to change the shape of the metal and give it greater strength by pressing. Such functionality will be most useful in the following areas:

- production of building elements of varying complexity;

- production of parts from round, sheet and tube rolled metal products in the machine-building industry;

- creation of steel furniture, decorative interior objects, cold steel, as well as other products of a similar kind (both home-made and factory-made).

Types of equipment: what are the machines for cold forging

The next step of our little research will be the distribution of the currently available devices according to their technical capabilities. This will allow you to more accurately determine the tool you need exactly for your purposes.

Gnutik

The main technically simple and uncomplicated device among the heroes of our review is a cold forging machine called "Gnutik". The device is capable of creating only two types of products - an arc or a ring. Nevertheless, it is with this device that most craftsmen begin their path in blacksmithing.

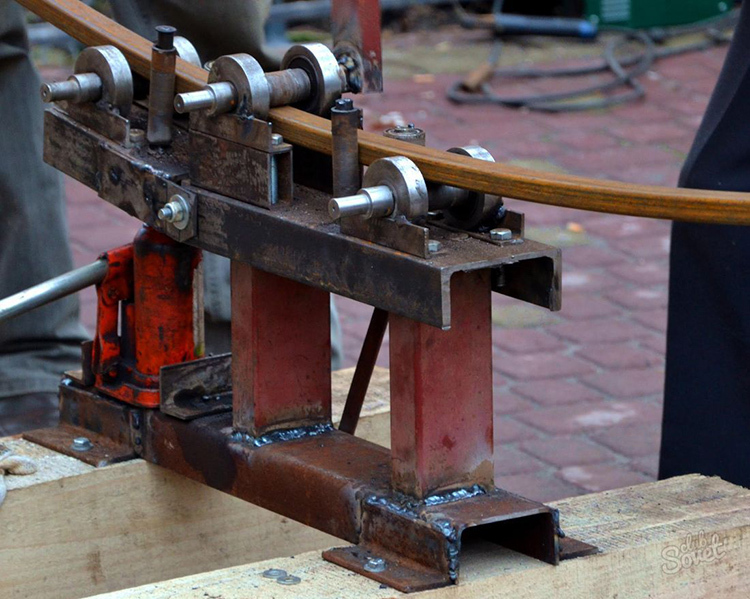

Wave

The next one is the minimalistic machine called "Wave". It is a series of shafts and rollers located at a certain distance from each other in space. Such equipment is also manual - the blacksmith independently moves the workpiece, giving it its characteristic shape.

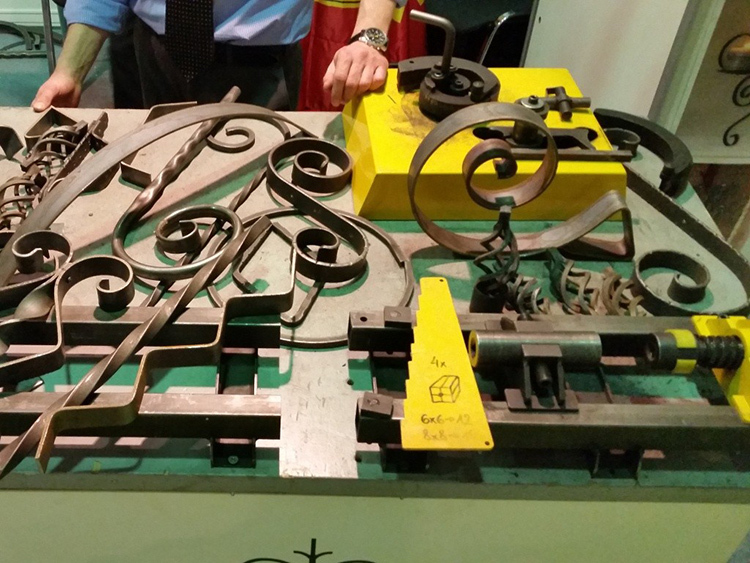

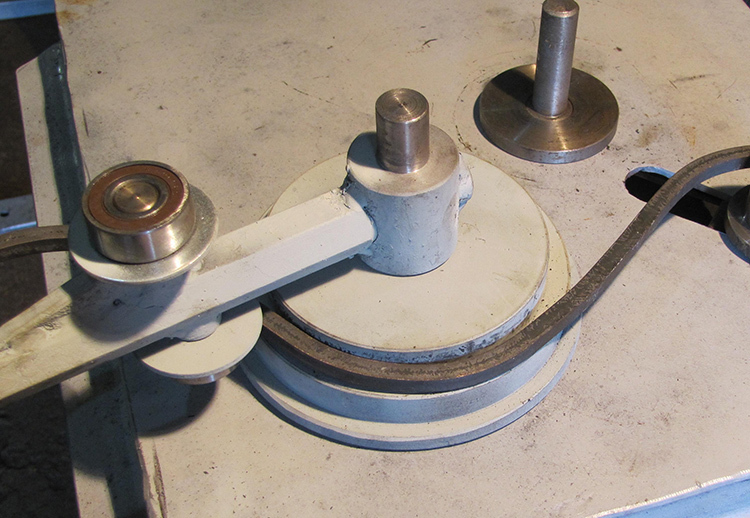

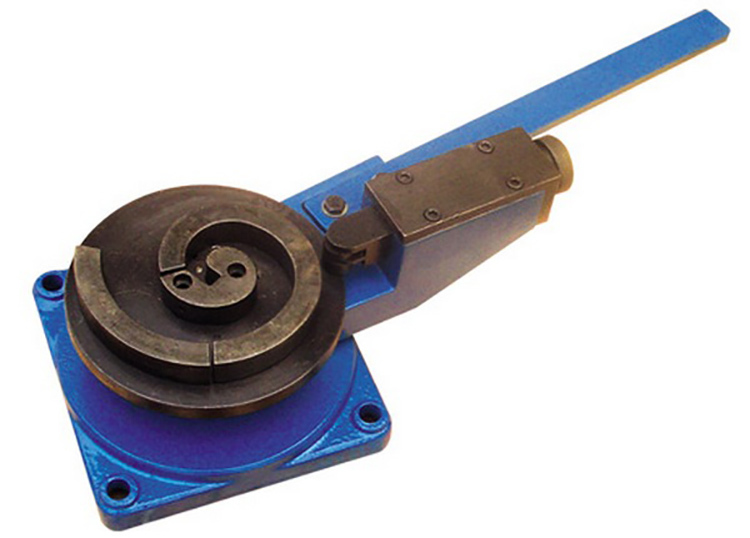

Snail

Another well-known, albeit unusual device is the so-called "snail". Structurally, it really resembles a cutaway shell of a mollusk. Due to such a device, the machine is able to create spirals, curls and similar decorative figures from bars and strips.

Twister

The next representative of the class allows you to rotate the steel workpiece along the central axis. Hence the unusual name, derived from the word twist (translated from English - "rotate"). The unit consists of two opposed vices, one of which has a swivel mechanism. As it moves, the metal bends, taking on a characteristic appearance.

Note! The device we have just described, unlike other modifications, has a number of other names. Seeing in a store or catalog the name "Torsion Machine" - know that this is an ordinary Twister. You can also find the "Flashlight" model - in fact, this is identical equipment, but it works simultaneously with several rods or strips.

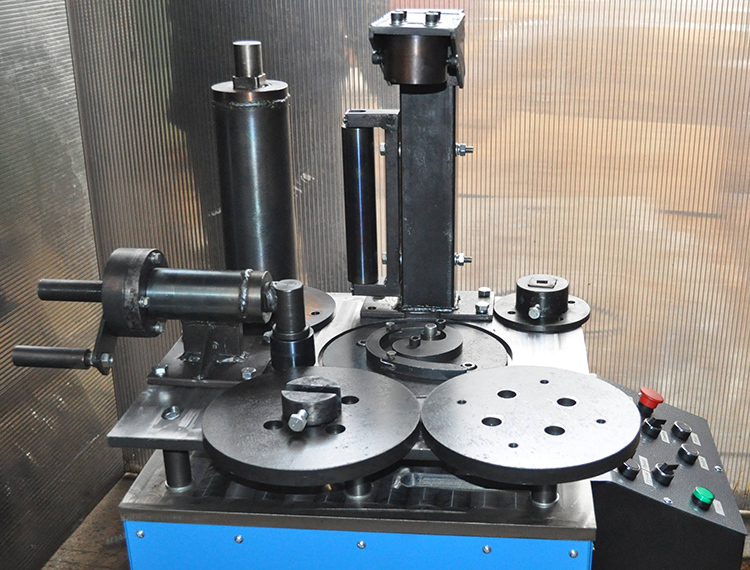

the globe

This creation of engineering thought definitely repeats the ideas embodied in the Snail. But in this machine, a completely different principle of operation operates: by placing and fixing the workpiece in one part of the apparatus, the blacksmith moves a special handle, giving the metal the shape laid down template.

Universal model

As an alternative to the options described above, there are devices that combine several functions at once. Having such a "machine" in your workshop, you can easily cope with the manufacture of both basic decorative elements and complex structures. But this multitasking has its downsides, but we'll talk about that later.

How to choose the right machine for cold forging: the main selection criteria

Having made the decision to engage in cold forging of metal, you are faced with the problem of choosing the optimal fixture. In order not to make a mistake at this stage, it is enough to determine the basic conditions. Let's take a direct look at each of them separately.

Method of work (control)

In this category, there are only two options - either manual or electric. The first method is best suited for beginners, since it allows you to quickly produce the same product without retooling. The version with an electric motor, on the contrary, is quite demanding on the skills of the master, but it is distinguished by high productivity and the ability to work with large-sized profiles.

Equipment manufacturer

An equally important aspect is the origin of the hero of our review. At first glance, it might seem that a quality factory product would be ideal under any circumstance. Yes, in 95% of cases this is exactly the case. But do not forget about the talented owners of "crazy pens". If desired, they can create from scratch a unique homemade tool with special characteristics.

By the way, since we are talking about factory models, it will not be superfluous to offer readers a small rating of machine tool manufacturers present on the domestic market:

| Brand name | The country of manufacture | Popular model | HouseChief score, score |

| Poland | Manual bending universal tool Stalex SBG-40 | 8,2/10 |

| |||

| Russia | Universal bending machine TRIOD SBG-30 | 8,7 /10 |

| |||

| Czech Republic | Manual sheet bending machine Proma UO-30 | 9,2/10 |

| |||

| Germany | Curl Bending Tools Blacksmith M3-V9 | 9,4/10 |

| |||

| Russia | Artistic forging machine Azhur-1M | 9,7/10 |

|

Many of the readers are wondering: is it really possible to make a working version of the device yourself from scratch? We answer with confidence - yes, it really is. Moreover, you can find a lot of real examples of such activities. The video below will show you just one of hundreds of possible variations. It all depends only on you and your desire!

Multitasking

As we said earlier, the heroes of our review can be both highly specialized and universal. And although the second option seems more profitable and productive, such a solution is not suitable for everyone. Firstly, you may need only one or two functions, and not a whole set of features - and this is already an irrational overpayment. Secondly, universal units fail faster, since they use too many resources. It will also be much easier for novice blacksmiths to understand the peculiarities of the work of a narrowly focused device for cold forging.

The cost of the apparatus

Finally, it would not be superfluous to mention the prices of products. In fact, it is not so easy to find a device for less than ten thousand rubles in this segment, which is why many strive to make homemade equipment. Nevertheless, factory-made machines are always relevant, especially for those who want to actively engage in the production of forged products of various types and purposes.

Features of the operation of machines for cold forging

After the decision has been made, and the model that is suitable for your purposes has been purchased and located in the place previously designated for it, you need to carefully prepare for its use. Although in most cases, operation is not associated with injury (unless damage to the electrical circuit can lead to dangerous consequences), a number of rules should still be followed:

- carefully check the reliability of the fastening of the part in the grooves of the equipment, otherwise, the element may take an irregular shape or even damage the device;

- a slight heating of the workpiece before starting work will simplify the procedure for making the desired product and give the metal additional useful properties;

- avoid sudden movements of the workpiece during work, controlling each stage. Failure to comply with this rule is fraught with poor quality results and premature failure of the machine;

- all shafts, rollers and other rotating parts of the apparatus must be periodically lubricated with machine oil for smooth operation.

The correct sequence of actions is also important when creating the next decorative or technological element. Each cold forging machine has its own order of metal processing. As an example, our editors took the Snail - look at this amazing procedure in a short video from a real master of his craft:

conclusions

So our excursion into the world of artistic cold forging has come to an end, which is impossible to imagine without a corresponding machine. We hope that after reading the materials of this article, you have discovered a lot of new and interesting things, and maybe even decided to try yourself in the role of a mighty blacksmith.

Maybe some of our readers are already familiar with this technique? Share your experiences and observations in the comments. And for today we say goodbye and leave you in the company of a very interesting video that will give the presented material additional meaning. Until next time!