Everyone knows that water absorption is one of the key parameters that determine the quality of insulation. And if the material is used in structures that are in contact with moisture almost 24/7, then this indicator is number 1 in the list of important properties. How much the insulation is able to withstand moisture will be shown by the results of the long-term water absorption test. What are these tests and what are their main advantages - we will talk about this in this article.

Read in the article

- 1 The history of the emergence of methods for studying the level of water absorption

- 2 Why is water absorption important?

- 3 XPS vs granular polystyrene - is there a difference in thermal conductivity?

The history of the emergence of methods for studying the level of water absorption

The construction industry is actively developing. New technologies appear, and with them solutions. A few decades ago, ordinary polystyrene foam was almost the only type of polymer insulation on the construction market, and today the variety of options is very wide, extruded polystyrene foam has appeared, which is in demand both in the cottage and in the industrial and civil construction. Together with technology, the regulatory framework is also developing, taking into account world experience.

So, in the very first GOST for foam plastic, a method for determining the water absorption of a material was fixed. It assumed that the sample was completely immersed in water for 24 hours. The key point is full immersion. After all, the material is used not only for insulating facades or roofs, but also in structures experiencing a more serious load from moisture: foundations, floors on the ground, blind areas. It was important to determine how much the insulation is able to maintain its properties in contact with water throughout the entire area.

It should be understood that the insulation in the construction of the foundation or blind area is in a humid environment for much longer than 24 hours.

In regions with abundant torrential rains and high groundwater levels, the load is further increased. It becomes obvious that these factors must be taken into account when assessing the water absorption of the material that is planned to be operated in difficult conditions. In Western practice, for such cases, the technique of complete immersion of the insulation for 28 days is used. The technique appeared in the Russian regulatory field a little later. It is described in detail in GOST EN 12087 (method 2A), which regulates the properties of extruded polystyrene foam. According to the requirements specified in this document, based on the test results, the sample must meet the following parameters:

| Level | Requirement, % |

| 3 | 3,0 |

| 1,5 | 1,5 |

| 0,7 | 0,7 |

In fact, this means that after 28 days of total immersion in water, extruded polystyrene foam has a water absorption of at least 3%, 1.5 or 0.7%. In fact, this means that after the test, water remains only on the surface or lateral faces of the samples. Water does not penetrate the closed cell structure of the XPS. The fact is that the cells of the extruded polystyrene foam are very small (0.05–0.08 mm), they are located close to each other, and there are no voids between them. It is for this reason that the material does not absorb moisture and does not swell. But the popular brands of granular polystyrene foam have a large-pore structure, the voids between the cells easily accept moisture, that is, the material gets wet upon contact with water.

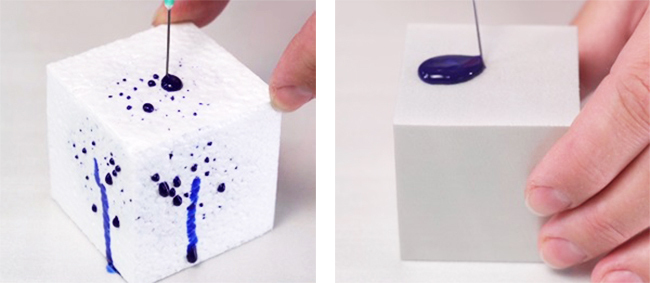

It's pretty easy to check at home. You can take a syringe filled with colored liquid and try to inject into the XPS plate and a sample of polystyrene produced in a different way. XPS will not let water through, a drop will form on the surface. And the liquid will easily penetrate into the stove of one of the budget brands of granular polystyrene.

Why is water absorption important?

Unlike insulation, water is a conductor and allows heat to pass through perfectly. For this reason, a wet insulation no longer fulfills its main function, the risk of freezing of structures increases. There is one more nuance: when water freezes, it expands in volume. If it gets into the insulation and turns into ice when freezing, then the material will certainly begin to collapse, deform and lose strength characteristics. In foundations, this is fraught with serious consequences for the concrete base and the entire building as a whole: from the appearance of cracks to complete destruction.

Long-term water absorption today, although it is not a mandatory requirement enshrined in GOST, is a key indicator of quality, especially in buried structures.

XPS vs granular polystyrene - is there a difference in thermal conductivity?

But what if, instead of extruded polystyrene foam, you use ordinary polystyrene? The consequences that can occur if the replacement is in the foundation, floors on the ground and other structures in contact with the ground have already been mentioned above.

Sometimes you can come across the opinion that both materials retain heat almost equally. This statement can be easily verified by a simple experiment published on the XPS TECHNONICOL YouTube channel.

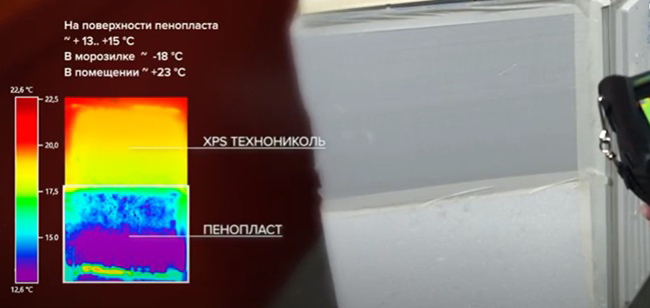

Take a freezer without doors and hermetically seal it on top with a regular polystyrene plate and an XPS plate on the bottom. Inside the freezer the temperature is -18 ° C, in the room + 23 ° C. An hour later, we check the temperature on the XPS surface with a thermal imager - it fluctuates between + 21– + 22 ° C. But granular polystyrene transmits heat better, on its surface the thermal imager records a temperature of + 19– + 20 ° C.

But in real conditions, insulation often has to deal with water. This means that it is important to understand how a wet material is able to retain heat. It is also easy to check this, for this you will need the same freezer, only pre-samples of foam and XPS need to be left in a bath of water with full immersion for several hours.

Experiment shows that the temperature of the XPS covering the freezer after immersion remains approximately the same as for the dry sample: + 19– + 20 ° C. The material was not saturated with moisture, and therefore retained all its original properties. But the granular polystyrene got wet, it began to conduct heat better, the temperature on its surface dropped to + 13– + 15 ° C.

Extruded polystyrene foam, due to its structure, retains low water absorption in the harshest conditions, with prolonged contact with water. And this property is especially important when constructing foundations, floors, blind areas. The quality and reliability of these structures affects not only the energy efficiency of the entire building, but also its structural reliability. It is impossible to replace the insulation in the foundation during operation, therefore it is most correct to initially choose the material, having excellent performance with long-term water absorption, as the manufacturer will certainly make a mark on the packaging.

It’s too much of a problem for you. Dyakuyu! Information bullet cikava, korisna i vchasna. I wish you good health and ...

My father, a notable carpenter in the area, said that a tree should be taken in November then wood ...

I like it very much, well done Julia Baranovskaya.

The title of the article promises accessories for organizing order, but in fact cardboard for rice ...

Brains are felt in everything. Even in the apartment (choice of a house, method of obtaining, footage, oh ...

Smart guy. I did not take a mortgage, but bought it out of a communal apartment, well done. And the 100m did not become ...

The author of the publication is RIGHT!!! They fight with us everywhere and for everything, and for which we are not obliged to pay ...

I would not call all the persons listed by you as descendants of Lenin. They may be called ...

I rarely write SUCH a comment but... Great article! And I really don't know a lot ...

I was also interested in the topic of the article, lavnoe, she calmly talks about the family of V.I.L ...

I completely agree with you. interesting, informative article, it's a pity that I don't know much ...

Lenin looks like dad - Ilya Nikolaevich, especially with the eyes of the Kalmyk type, like his ancestor ...

If I were you, I would solve such a question with competent people who understand this ...