Electrical appliances cannot last forever. For example, in a hand blender, the weakest part is the attachments. They often fail. It turns out that the handle with the motor is still quite suitable for work, but without attachments it is useless. And it's a pity, because in this situation the whole device has a direct road to the trash can. But do not rush to draw a conclusion. It is possible to use the engine of this device in a new form. A master class on this matter was shown by the author of the YouTube channel Evgeniy Budilov. Perhaps this experience will be useful to you, especially since it is not at all difficult to repeat it.

Read in the article

- 1 How to disassemble a blender for rework

- 2 Additional details for reconstruction: what to buy

- 3 Final assembly of the engraver from the blender

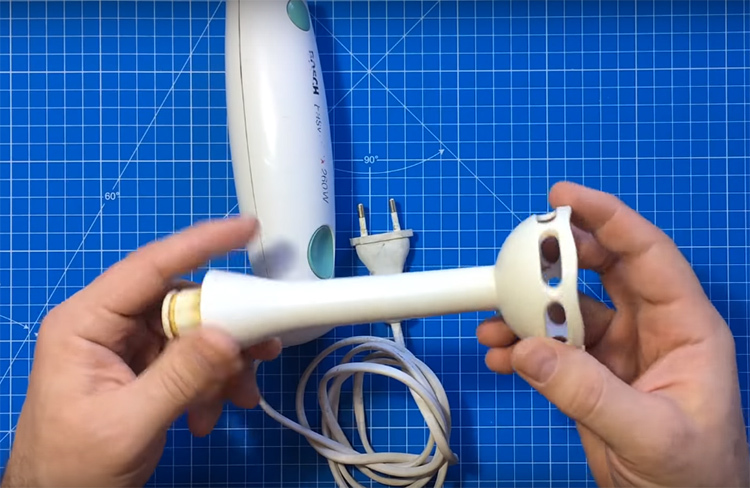

How to disassemble a blender for rework

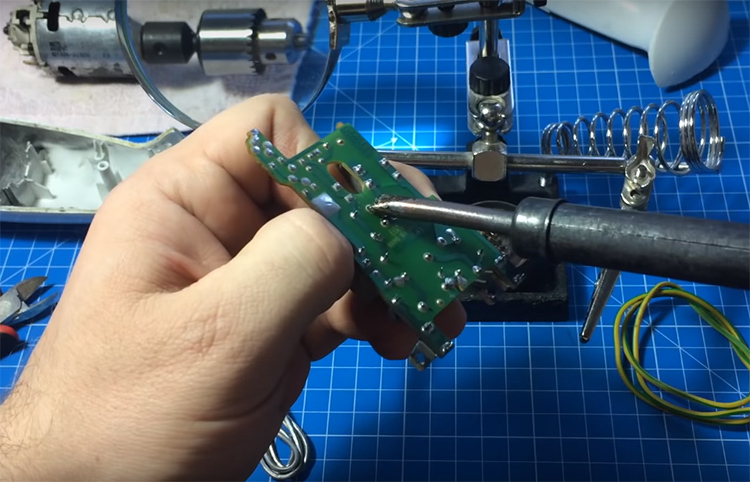

To make minor changes to the existing design of the device, you will have to disassemble it, and get rid of some parts altogether.

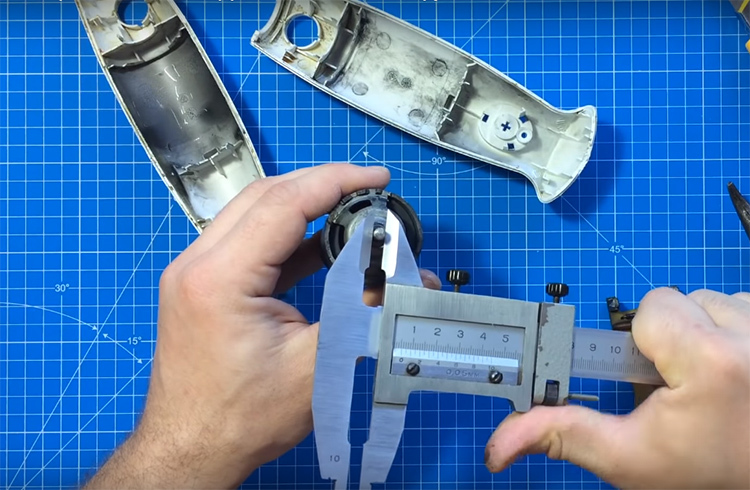

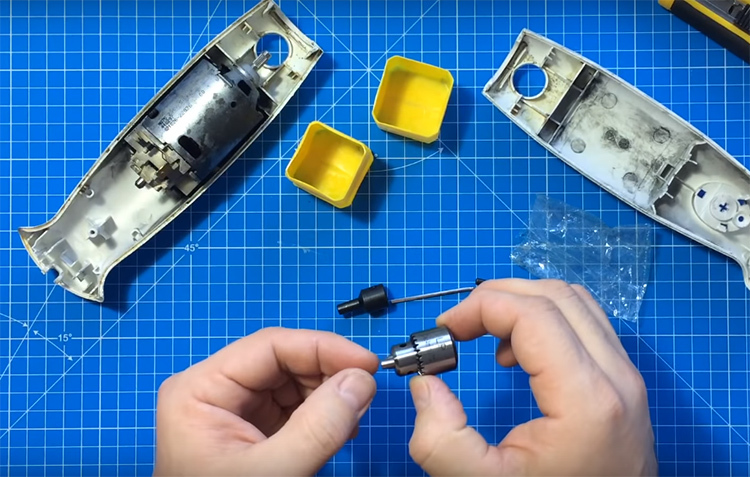

Additional details for reconstruction: what to buy

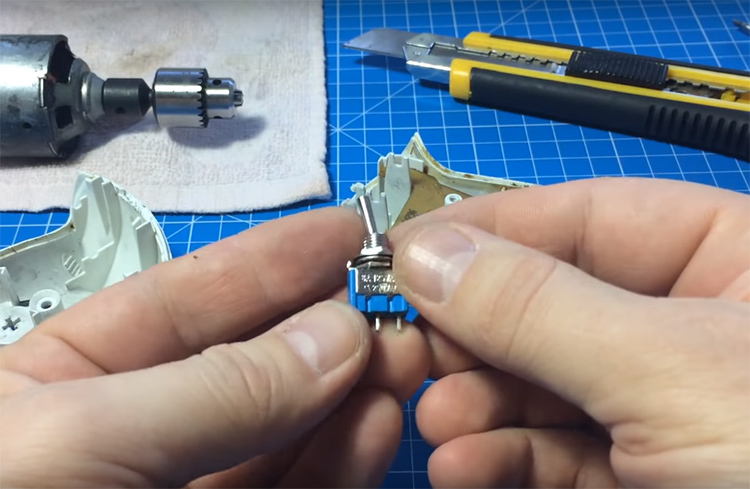

The blender design has a button that is not very convenient to control the engraver. In addition, a special tool is required to attach a drill or other accessory to the motor.

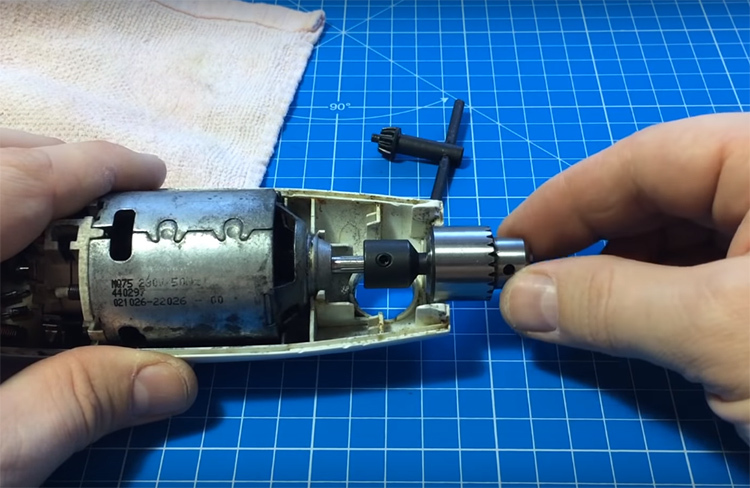

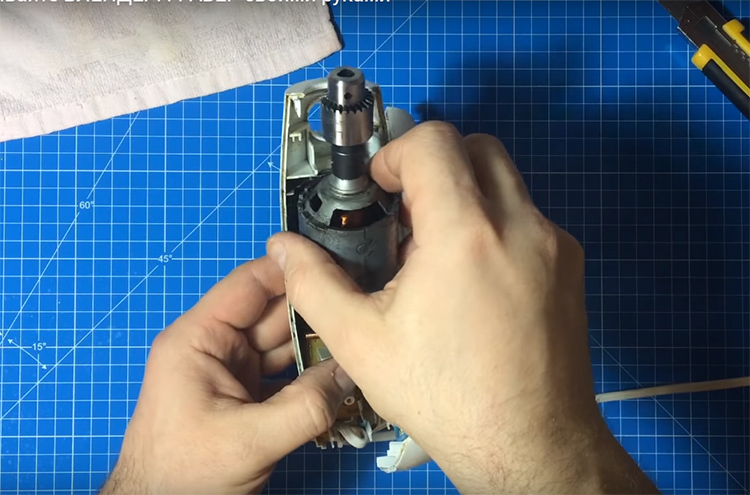

Final assembly of the engraver from the blender

All the necessary changes to the design have been completed. There are not many new parts, moreover, they do not take up extra space.

This is a very simple alteration that does not require any radical changes in the design. Of all the additional parts, you only need a drill bit and a simple switch. The blender body in a plastic shell fits comfortably in the hand and weighs relatively little. The power cord remains standard. So, if you prepare in advance, all the work will take you from the strength of an hour and a half, and, instead of the device that you already were ready to send to the landfill, you will have a useful and practical thing that will definitely come in handy in farm. It must be said that such an alteration is one of the most popular and widespread among the authors of video channels. Here's another example of such a reconstruction:

In this version, you can get an engraver with speed control, which is sometimes very convenient.

How did you like this idea of converting an old blender into a hand engraver? Did you understand everything in the master class? Could you repeat it yourself? If you've done something similar before, share your impressions of the power of the device in the comments! And if you have come up with another way of using the old blender, send us your photos of the process with a description, we will be happy to publish your master class.

PHOTO: YouTube-channel "Evgeniy Budilov»