Whatever nutritionists say, many of us love to feast on smoked sausage, bacon or fish. Light aromatic smell of smoke, golden crust and delicate structure of the product will not leave anyone indifferent. But modern manufacturers use the so-called "liquid smoke" to reduce the cost of the process, but this is still chemistry that is hardly useful for our body. In today's HouseChief review, we'll show you how to make your own hot smoked smokehouse so you can continually feast on homemade delicacies.

Read in the article

- 1 Features of hot smoking

- 2 The device and principle of operation of the hot smoking apparatus (AGK)

- 3 How to make a metal smokehouse

- 3.1 Smokehouse made of sheet material

- 3.1.1 What you need to work

- 3.1.2 Step-by-step instructions for making a smokehouse

- 3.2 Barrel as a smokehouse

- 3.2.1 Materials, tools and drawings

- 3.3 Smokehouse from a bucket or pan

- 3.1 Smokehouse made of sheet material

- 4 Capital smokehouse made of bricks

- 4.1 Materials and tools

Features of hot smoking

Smoking is the heat treatment of food by means of smoke. It is used for cooking meat, sausages, lard, fish, some types of cheese, vegetables, fruits, etc.

There are two types of smoking: cold and hot. The fundamental difference between them is the temperature of the smoke used to process the products and the fumigation time. It takes up to 3 days to smoke meat or fish in a cold way, while hot smoking takes no more than 4 hours. The cooking time is influenced by the type of food and its size. So, for example, an average mackerel will take no more than 30 minutes, and a pork leg will take much more time. However, in the first case, products can be stored in the refrigerator for up to one year, and in the second, no more than a week.

The device and principle of operation of the hot smoking apparatus (AGK)

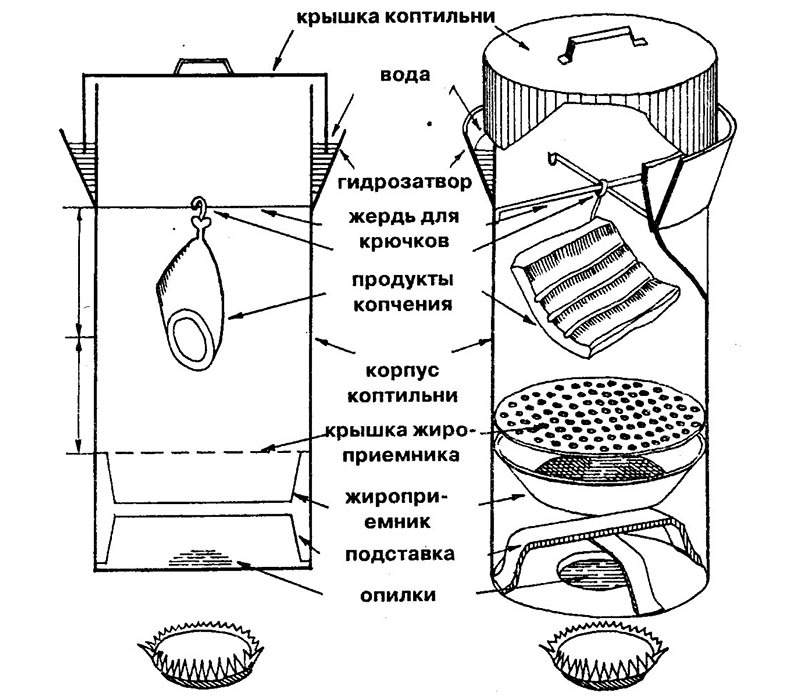

Modern manufacturers offer a wide range of designs for cold and hot smoking, but, knowing the device and the principle of operation of the smokehouse, you can easily make it yourself, even from assistants materials. Almost all AGKs consist of:

- hulls;

- covers;

- water seal gutter along the perimeter;

- racks or rods with food hooks;

- grease receiver;

- chimney fittings;

- thermometer.

Some models may not be equipped with a water seal and thermometer. However, a trough with water, into which the lid is inserted, increases the tightness of the structure, and the thermometer helps to adhere to the technology of smoking products.

Small wood chips (oak, alder, apple, cherry) are placed at the bottom of the smokehouse. A grease collector is installed on top of the stand, over which grates or rods with processed products are placed. The container is closed with a lid, and water is poured into the gutter of the water seal. After that, the smoker is set on a fire, gas or electric stove. Sawdust heats up from indirect action and begins to smolder. As soon as the first smoke appears, the time it takes to smoke this or that product is recorded in accordance with the technology. An external heat source heats the container up to 100ºC, and the smoke temperature must be at least 50ºC.

Related article:

Do-it-yourself cold smoked smokehouse. Video, photos, recommendations. How is the smoke generation process for cold smoking? Varieties of cold smoking apparatus, cold smoking at home. The design of the smokehouse, the choice of chips for cold smoking, how to make a cold-smoking smokehouse with your own hands - read the publication.

How to make a metal smokehouse

The most popular material for the manufacture of AGC is metal. It can be sheets, barrels, cylinders and even a regular bucket. Metal smokehouses, depending on their size, can be installed in the country, taken for a picnic or used in a regular city apartment. Let's consider step by step the options for making structures from sheet metal, a barrel and an old bucket.

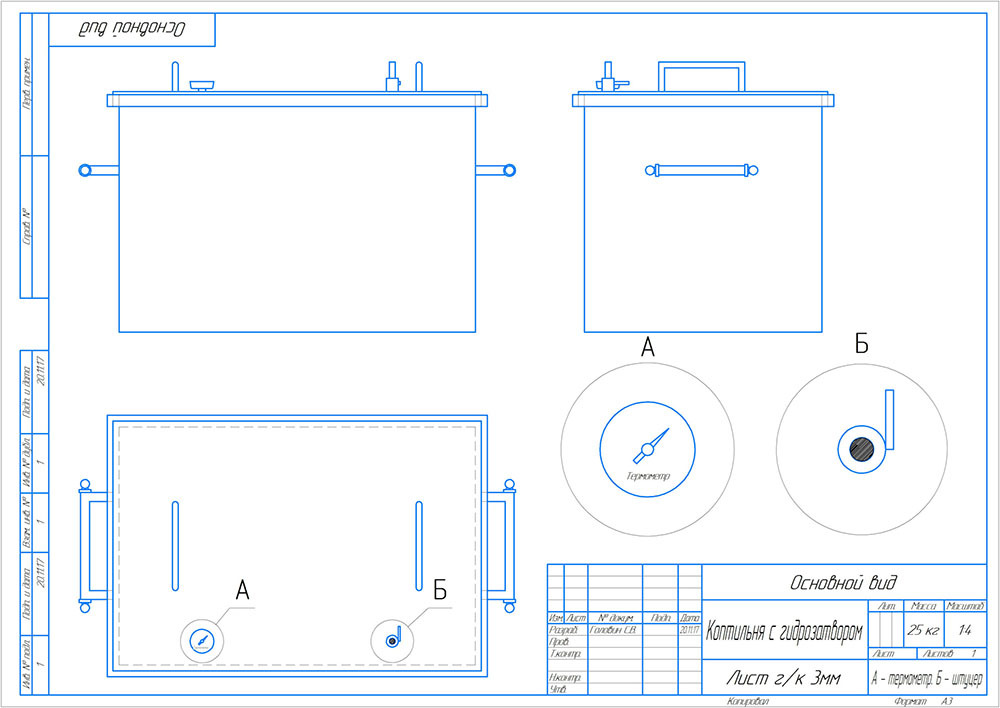

Smokehouse made of sheet material

Making a smokehouse from sheet metal is difficult only because it is necessary for this. welding machine. The rest is very simple. It took about 7 hours to create this model.

What you need to work

To make a smokehouse you will need:

- drawing;

- a strip of sheet metal with a thickness of 1.5-2 mm;

- tape measure, square, marker;

- impeller with cutting and grinding disc;

- welding machine;

- metal corner;

- welding electrodes with a diameter of 3 and 6 mm;

- pipe branch.

Step-by-step instructions for making a smokehouse

It was decided to make the structure from a strip of metal. It was previously cleaned of rust.

| Illustration | Description of action |

| The height of the box will be 280 mm, length - 520 mm, and width - 310 mm. Metal thickness - 1.5-2 mm |

| We mark the metal in accordance with the dimensions of the structure |

| Checking with a metal square |

| Using an impeller and a disc, we make shallow cuts along the marked lines |

| Bend a strip of metal along the cuts made |

| We get such a box |

| We boil the junction |

| We also cut out three pieces of metal. Two - 540 × 333 mm (for the bottom and grease collector). One piece - slightly larger (we select it empirically) for the lid |

| We make pallets with 10 mm sides from metal sheets for the bottom and grease collector. Boil the bottom of the smokehouse outside |

| Weld a metal corner in the upper part of the device around the perimeter. This is how we create a water seal gutter |

| We put a grease collector into the structure, to which 4 pieces of a metal corner are welded from below, which play the role of legs, and supports for the grid, made of electrodes with a diameter of 6 mm |

| In the photo you can see the lower grid of electrodes. |

| The upper food rack is made in the same way. |

| The lid of the smokehouse is made with a slight bend so that the condensate drains into the water seal. It also has a welded pipe for exhausting smoke. |

| As a result, we got such a smokehouse, which can be used both in the apartment and in nature. |

Related article:

Do-it-yourself smokehouse for cold and hot smoking: principles of the device and examples of making with your own hands, what stationary smokehouses look like for a country house, options for folding and camping smoking devices - read the publication.

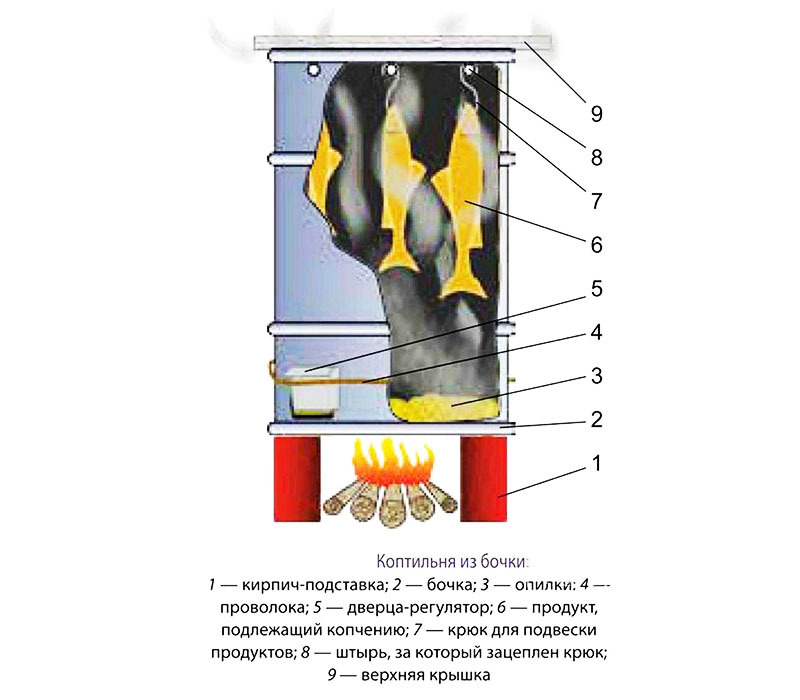

Barrel as a smokehouse

A simpler version of the AGK is a smokehouse from a metal barrel. Of course, this design is not as compact as the previous version, but it is more spacious and perfect for a summer cottage.

Materials, tools and drawings

So, to make AGK with our own hands, we need:

- metal container with a volume of 200 liters;

- Bulgarian;

- electric drill;

- door hinge;

- metal rod;

- finished metal pallet;

- brick or paving slabs.

For manufacturing, you can take an old or new container with a volume of 200 liters

| Illustration | Description of action |

| We take a metal barrel (if necessary, we clean it) |

| Cut out the bottom along the inside of the rim. The resulting circle will protect the sawdust from grease. |

| We also cut off the top along the contour, stepping back from the edge 50-70 mm |

| In the lower part, we mark the blower door and cut it out with an impeller |

| We attach the door to the body of the smokehouse using self-tapping screws and hinges |

| Further, stepping back from the bottom a third of the height of the barrel, mark and drill 3 holes with a diameter of 8-10 mm |

| Insert the bolts into the holes and fix them with nuts. These will be the stops for the grease collector. |

| Drill a hole in the center of the grease collector, insert the bolt and fix it with a nut. We insert the circle inside the body of the smokehouse |

| We mark 8 holes in the upper part of the body and cut 4 rods of the required length |

| We insert the rods into the holes, as shown in the photo. Hooks will be placed on them for hanging the processed products. |

| In order not to dig a hole for firewood, we lay out a platform made of bricks or paving slabs. We install a ready-made cauldron of a suitable size (you can make a pallet yourself or, as in our case, buy) |

| We install the smokehouse on a pallet and start smoking lard, poultry, meat, etc. |

More detailed instructions can be seen in the video:

Smokehouse from a bucket or pan

The easiest way to make a hot smoked smokehouse is from an old bucket or pan with a capacity of 10 liters. This requires a minimum of tools, work and time. A food net can be made from a wire rack from an old oven or refrigerator, and even from a mold for molding dumplings.

Check out the step-by-step video tutorial on how to quickly and easily make a hot smoked smokehouse from old boiled water:

Capital smokehouse made of bricks

The brick smoker is more solid and spacious. Such a design in a private household or in a summer cottage even allows you to create your own business for the production of hot or cold smoked products. The proposed model will be located in the finished building of the utility block, which solves several problems at once. Let's see what we need to build a capital brick smokehouse.

Materials and tools

To build a smokehouse, you will need a brick, preferably fireproof, cement or clay, metal sheets, a corner, boards, a door, a firebox door, a galvanized pipe and fittings. From the tool you will need:

- shovel;

- container for mixing the solution;

- Master OK;

- pick;

- electric drill;

- grinder with a cut-off wheel or jigsaw with a canvas for metal.

| Illustration | Description of action |

| On the finished concrete floor of the utility block, we mark and lay out the first two brick rows of the future smokehouse |

| We make an opening in the combustion chamber under the door |

| We raise the walls of the smoking chamber, laying out the brick in a checkerboard pattern |

| We drive out the masonry to the height of the door frame and insert the frame |

| We align the masonry and expose the formwork under the ceiling fill. Be sure to make a hole for the exhaust pipe |

| Fill the ceiling with concrete mortar |

| From the inside, under the exhaust pipe, we attach a protective screen, and on the walls we fasten the corners for rods or rails with hooks |

| Installing the combustion chamber door |

| We hang a mosquito net and a capital metal door of the smoking chamber. A thermometer must be installed in the smokehouse to monitor compliance with the technology and smoking process |

| The smokehouse is ready to go and soon you can enjoy the result |

As we have already said, such a capital structure will even allow you to open your own small business for the production of smoked food.