Each of us wants his clothes to look neat. But it can be very difficult to achieve this at times, especially if the iron that is at hand is not equipped with a steamer. But it is much worse if such household appliances fail. After all, not everyone can afford to just go to the store and buy an iron like a loaf of bread. In today's article, the author of the YouTube channel Remonter offers his own vision of this problem and faces a choice whether it is always worth taking on the repair of such equipment.

Read in the article

- 1 Visual inspection for the purpose of troubleshooting

- 1.1 Checking the iron in a workshop or garage

- 1.2 Filling the tank with water

- 2 Dismantling the iron, finding leaks

- 2.1 Inspection of the internal parts of the repair iron

- 2.2 Steam chamber and problems associated with it

- 3 Solution to the problem: what to do in this situation

- 4 Final part

Visual inspection for the purpose of troubleshooting

Initially it was known from the words of the owner that the iron taken for today's example suddenly began to leak, something sparkled inside, and the smell of burnt plastic was felt. Naturally, the device was immediately disconnected from the power supply. Where to start troubleshooting? Of course, with logical thinking.

The iron may leak if the water tank or steam chamber is damaged. There are practically no other options here. In this case, sparks under the plastic are understandable.

Checking the iron in a workshop or garage

You must personally check how the iron behaves after turning it on. Here is a warning to novice home craftsmen. It is not necessary to plug the known faulty equipment into ordinary sockets. It is best to use a surge protector for your computer for these purposes. Its automatics will cut off the power in case of an emergency.

The check showed that the heating element of the device is normal and is operating normally. At the initial turn on, no sparks, no foreign smell appeared. But this is understandable, because there is no water in the iron, which means that there is nothing special to close.

The thermostat should also be checked. His work did not cause any complaints. It switched with a characteristic click, the indicator on the case showed how the thermostat turns on and off the power from the heating elements.

Filling the tank with water

Now it was necessary to turn off the iron, let it cool down a little and try to pour water. In fact, only she could cause the problems described by the owner.

But as soon as the tank was half full, the sole of the iron began to get wet. The further bay was already superfluous. Naturally, with such a strong leak, the iron could not be turned on. And this is useless, because the general problem has already become clear.

It is worth noting that when repairing household appliances or power tools, at least basic safety rules must be observed. One of the unwritten rules of an electrician is the following: if you have the slightest doubt, you should not apply voltage. Better to double-check everything several times.

Now it was necessary to completely drain the water from the tank, and then disassemble the case in order to get to the contacts of the heater and the steam chamber.

Dismantling the iron, finding leaks

It is very simple to understand such irons, and therefore there is no need to paint this action in detail. The only thing worth paying attention to is the shape of the slots of the fastening screws. For example, on the Tefal iron, all screws are unscrewed with a hexagon, and on some models, with an asterisk. As for budget equipment (like "Vitek"), then in such irons, most likely, hardware will be used for a Phillips (curly) screwdriver.

Step by step, the body is removed from the sole. The water tank remains in the housing. This is probably the easiest stage of all the work ahead.

Next, you need to remove the plastic casing so that the condition of the steam chamber can be assessed.

Inspection of the internal parts of the repair iron

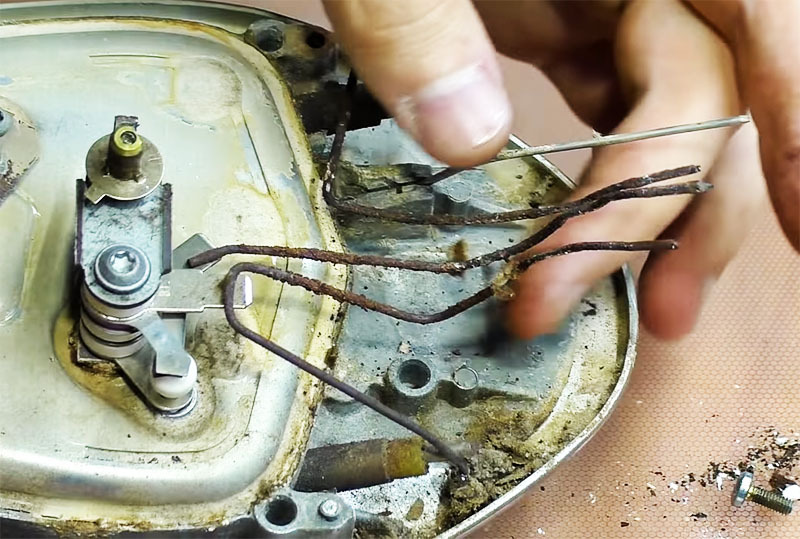

One had only to look at the iron from the inside, as it became clear that the owner was clearly being cunning, talking about a single leak. Oxidation and rust on the contacts indicated that water had been flowing here for more than one month. Therefore, it was necessary to remove the plastic casing and look at the condition of the steam chamber.

Now the problem arose of dismantling the current-carrying conductors. It was not easy to pull them out of the terminal block - they got rusted, got used to it and categorically refused to "leave their homes." Neither the silicone grease nor the WD-40 helped, so they had to resort to more brute force. As a result, the veins were pulled out with pliers. After removing the casing, the sole looked even more deplorable.

Steam chamber and problems associated with it

Upon closer inspection, even with the naked eye, it became clear that it was the steam chamber that was to blame for the leak. At the welded joints, the metal began to creep, which indicates overheating of the dry iron. The case is not an isolated and quite common one. However, such problems in the early stages can still be solved, but if you start, then no treatment will help the iron. An extremely neglected case was seen here. The sealant that was applied to the manufacturers along the seams peeled off in a circle, which, coupled with rusted current-carrying veins and leaks of the steam chamber suggested that this piece of iron has long been asking to the landfill.

Solution to the problem: what to do in this situation

The only way to save the life of such an iron was to replace the sole with a steam chamber with a new one, the old one was no longer repairable. But the problem here was that the cost of purchasing a new part is almost comparable to an iron. So does it make sense to change the part? It is much easier to purchase an iron by sending this one to junk. Although for a summer residence, it is still quite suitable. The main thing is not to pour water into the tank. This means that you should thoroughly clean it inside, reassemble it in the reverse order and completely muffle the filler neck so that there is no temptation. Then the iron can serve for some time.

The main thing is that the heating element of the sole and the thermostat are fully operational. And the fact that there will be no steam, so after all, even relatively recently, they did not even dream of irons with a similar function. Well, and finally, we suggest once again admiring the extent to which people do not value their health and even life.

Final part

I would like to appeal to everyone who uses various household appliances. After all, everyone knows how this or that device should work. At the slightest deviation from the norms, the appearance of an extraneous smell, sound, moisture in places where it should not be, stop using the device. It must be urgently carried to the master or repaired with your own hands, if you have the necessary skills. This is the only way to protect your home and the health of your family. And health cannot be compared with the cost of even the most expensive iron.

We really hope that today's article will be useful to the dear reader, and he will use the advice reflected in it. Perhaps you have any questions about the topic. In this case, feel free to ask them in the discussions below. HouseChief editors will definitely answer each of them as soon as possible. There you can also comment on what you have read, express your opinion about the style and content of the article.

What do you think, does it make sense at all to repair household appliances or is it easier to buy a new one in a store? Write your answer in the comments. If you liked the article, please rate it. Your opinion is very important to us.

PHOTO: YouTube-channel "Remonter»