In addition to tools in the workshop, various stands are absolutely necessary, which facilitate the work and provide additional opportunities for using familiar tools. Various work tables and stands for electric tools play a special role in this. Grinders, saws, drills - all this can get updated functionality precisely due to additional devices. For example, mechanizing the control of a drill allows you to reduce the stress on your hands and perform precise work, like on a drilling machine. On sale you will find various options for such racks at a price of 2,000 rubles. and higher. But in principle, you can do such a design with your own hands, it is not so difficult and, moreover, allows you to adjust the tool to your needs and physical parameters. YouTube channel author Grumbler's Workshop offered two options for the execution of such a design, perhaps one of them is right for you.

Read in the article

- 1 A little about the necessary materials and tools

- 2 How to assemble the base of the rack

- 3 Fixing the rack to the platform

- 4 Rack control mechanism

- 5 Practice with a homemade rack

A little about the necessary materials and tools

The most profitable option is to use the materials at hand, so do not rush to buy, perhaps you will find most of the parts in your bins. First of all, you need a 20 × 20 or 25 × 25 profile pipe. On average, a segment with a length of 120 cm is enough.

In addition to the pipe, you need a pair of metal corners. If there are no ready-made ones, you can make them yourself. You will also need two perforated plates, mounting bolts, a metal cable, a platinum metal lever handle and a piece of cable.

Prepare a file for metal, a drill and a wrench from the tool. The beauty of this model is that no welding is required.

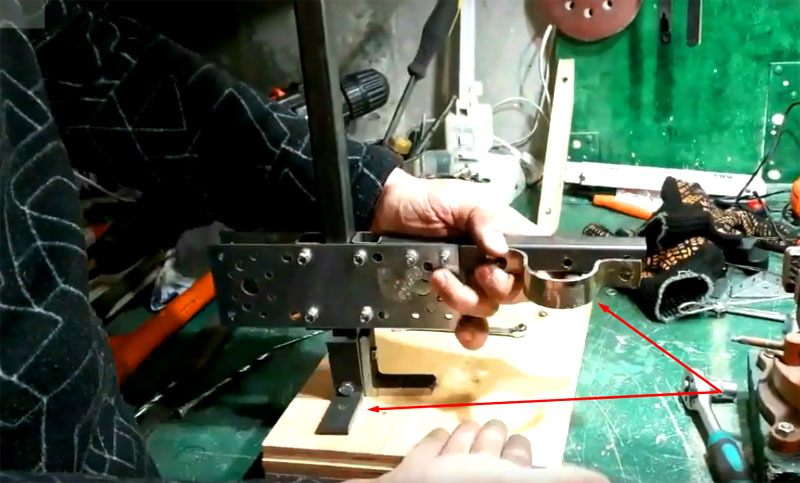

How to assemble the base of the rack

What's important in a drill stand? Strength, mobility and the right height. Strength will be provided by a profile pipe, but mobility will be due to a special design and a lifting and lowering mechanism.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

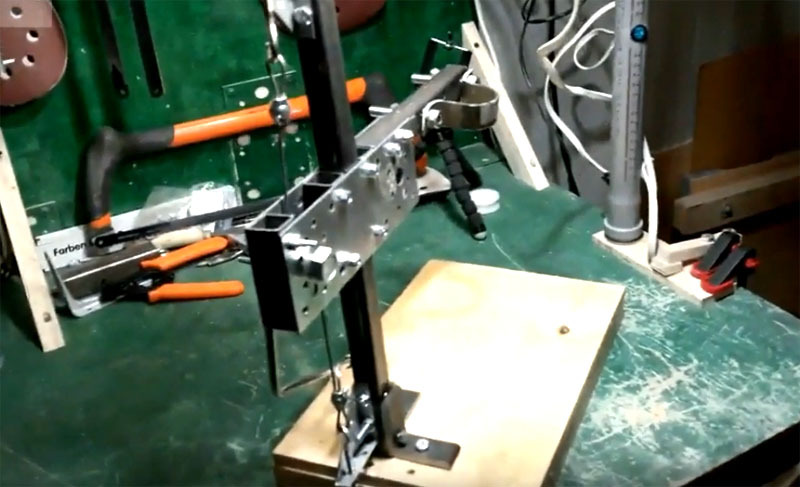

PHOTO: YouTube.comFixing the rack to the platform

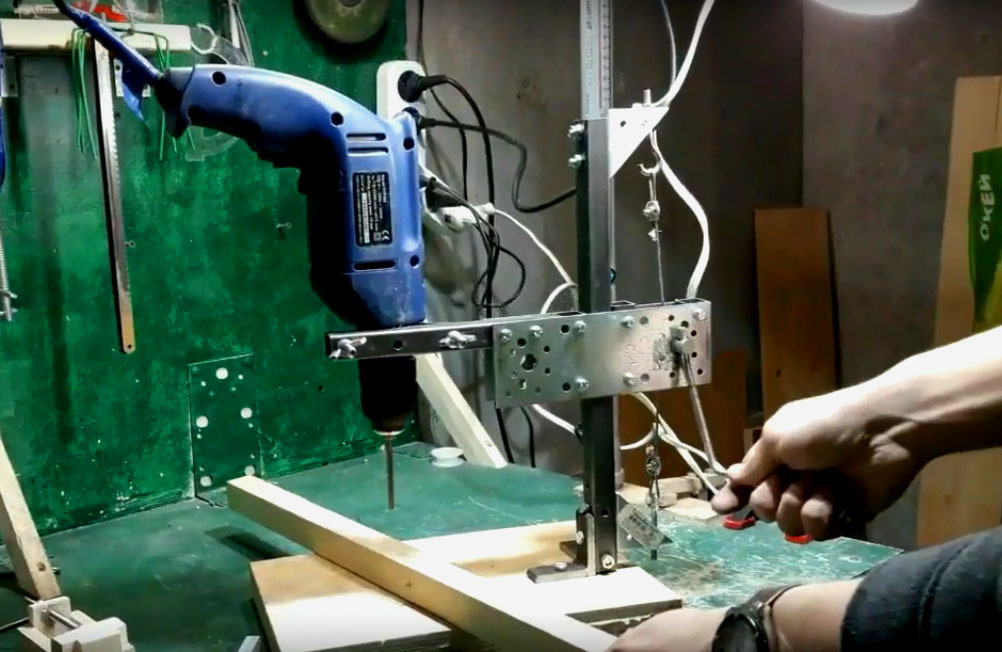

Your structure should be stable on the workbench. This stability will provide a wide platform, which is better made of solid wood. Keep in mind: together with the drill, the stand will weigh a lot, so the platform should be at least 20 × 30 cm.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

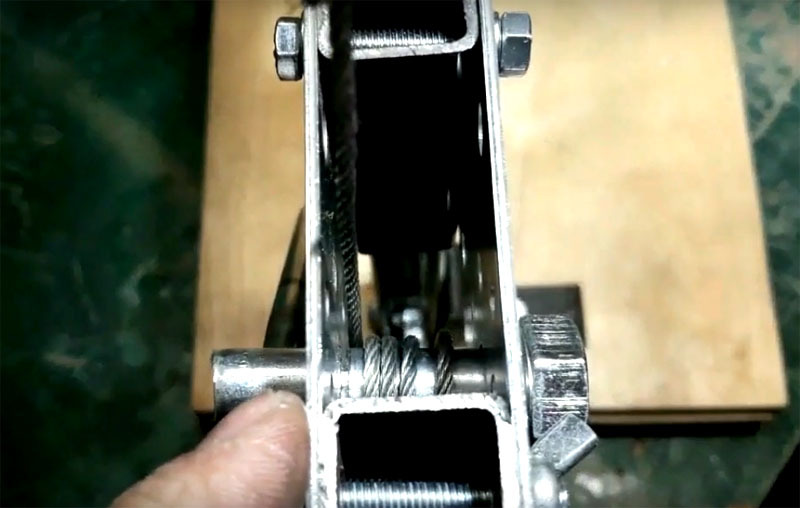

PHOTO: YouTube.comRack control mechanism

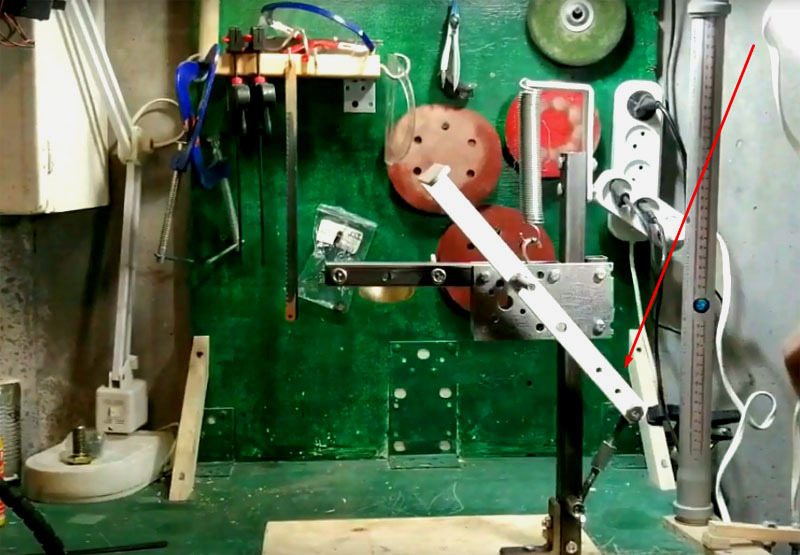

As already mentioned, the author has proposed two ways to control the rack. Both are quite effective, but have proven to be different in practice.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

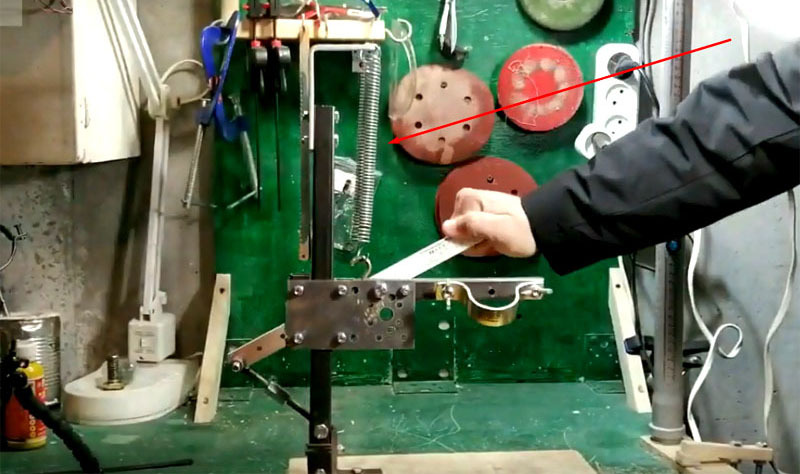

PHOTO: YouTube.comPractice has shown: such a mechanism is easy to operate, but does not give the required pressure on the drill, the stand moves in jerks. This is not the best option from the existing ones, although you can get used to it. The second version of the device turned out to be much more convenient in practice.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comPractice with a homemade rack

It is very easy to work with such a rack.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comThe device is primitively simple, assembled without welding, which is very convenient. The most difficult thing in all the work is to cut the profile into the required segments. Everything else will take a few minutes.

And here is another stand that is not difficult to perform and is available in terms of materials in the video master class:

What do you think about the presented model? How clear and accessible was this master class? What's left behind the scenes for you? Write about it in the comments! Send us a photo of your designs with a description of the manufacturing process! The most interesting master classes will certainly be published!