The use of petal attachments is very convenient when you need to sand a complex surface. These nozzles are of two main types: disc and circle. The discs are used for the grinder and are attached to it in a standard way. And the circles are attachments for a drill with a pin for fixing. Both of these options are very much in demand in various jobs; such attachments are durable and work until they are completely abraded. But working with such a nozzle on a drill is not very convenient due to the position of the petals, you have to hold the tool sideways, which interferes with the view. With a grinder, everything is much more convenient. But it is impossible to fix the circle on the grinder due to the lack of a cartridge corresponding to the fastening. The cartridges are on sale, but it is not easy to find them for the grinder, suitable copies are extremely rare to find. It is possible to order the adjustment of the chuck to the turner, but here is the author of the YouTube channel StoDel_56 from his own experience he demonstrated how you can do on your own in reworking the cartridge. Perhaps you will be interested in this experience.

Read in the article

- 1 What is required for rework

- 2 Chuck boring for grinder

- 3 Modification of the cartridge to eliminate runout

What is required for rework

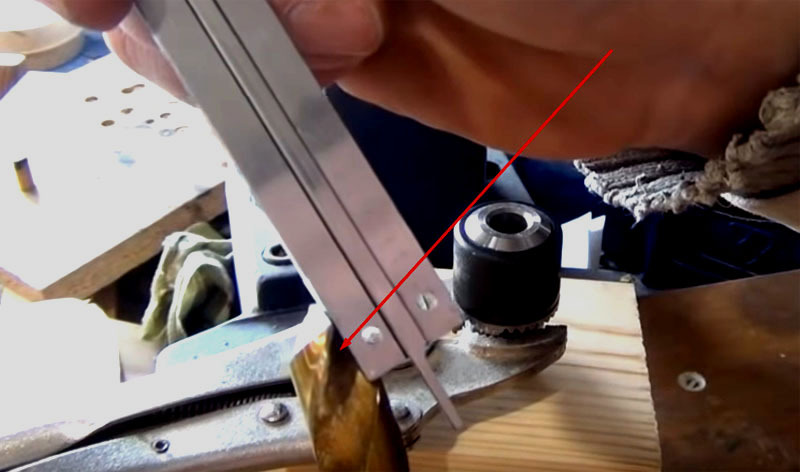

It is not easy to remake a chuck for a grinder without a turner, but in principle it is possible. It should be noted right away that the accuracy during manual alteration will be imperfect and you will still need to spend time on fitting and grinding.

PHOTO: YouTube.com

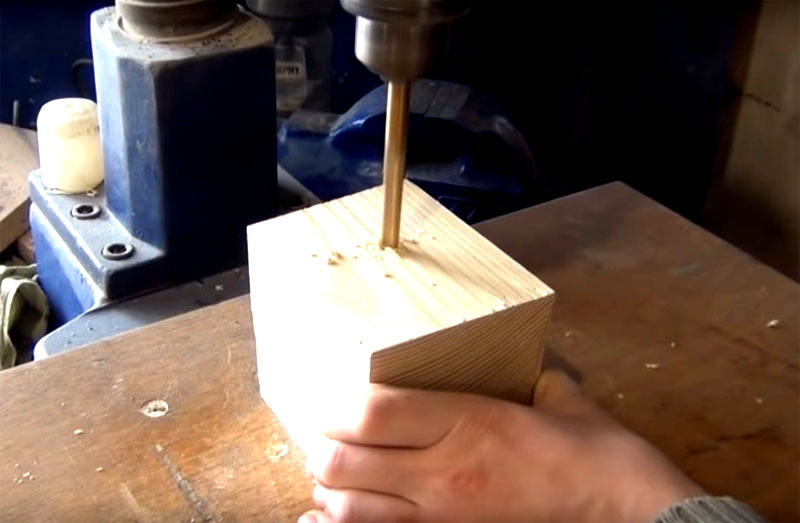

PHOTO: YouTube.comFrom the tools you need a drill on a stand with drills of different diameters. Prepare pieces of timber to fix the chuck in the process.

Chuck boring for grinder

To work with the chuck, it must be securely fixed. This will require a piece of timber and a drill.

PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.com PHOTO: YouTube.com

PHOTO: YouTube.comModification of the cartridge to eliminate runout

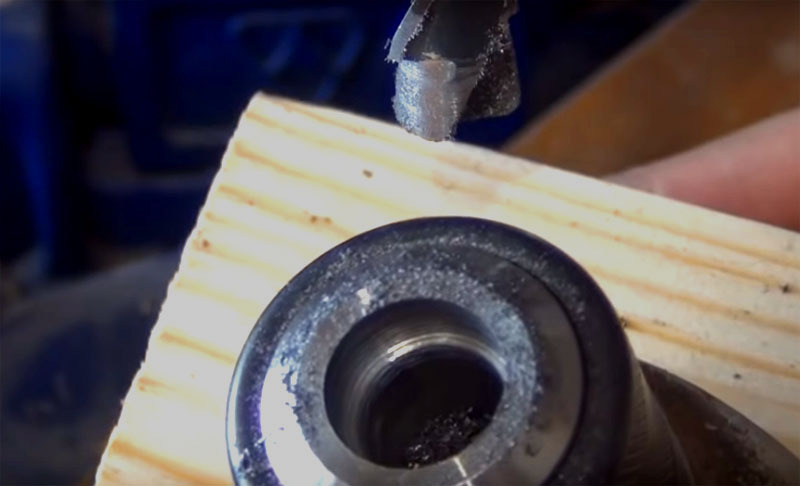

Even if you did this whole procedure on a lathe, there would still be a slight beating. The problem is that when tapping with taps, it is difficult to maintain alignment, so in any case, you have to modify the cartridge. The cutter, of course, gives more precision than the taps.

PHOTO: YouTube.com

PHOTO: YouTube.comYou are unlikely to be able to completely eliminate the beating, but it is possible to achieve a very decent result. Additionally, the chuck head can be ground from the outside to eliminate vibration.

This homemade product is only suitable for petal drums. Do not use it for drilling, it can be dangerous due to too high a speed. Do not risk using cutters in such a chuck, the cutter can bite and snatch the tool out of your hands. But for flap drums and end grinders, the tool will definitely come in handy. Thus, a homemade cartridge will solve problems that are non-standard for a grinder.

PHOTO: YouTube.com

PHOTO: YouTube.com

You can supplement this material with a small video on repair work on the drill chuck, this knowledge may be very useful to you in the future:

Share your opinion on this experience in the comments! How effective do you think such a grinder attachment will be? If you have experience in the manufacture of similar products, send your photos of the process and a detailed description. We will certainly publish the most interesting materials.