When making clothes or accessories, many are faced with the need to fix decorative elements on the main canvas. This can be done in different ways. Someone sews on the decor, someone glues it. In the latter case, fabric adhesives are used, the types, application and manufacturing features of which may differ significantly. Knowing the specifics of each composition, you can decide what is the best way to finish the manufactured product.

Read in the article

- 1 Features of the manufacture and use of different types of fabric adhesives

- 1.1 Hot melt adhesives in powder and solid state

- 1.2 Polyurethane-based waterproof adhesives

- 1.3 Professional formulations with styrene butadiene

- 1.4 Universal adhesives in tubes

- 1.5 Adhesive "liquid thread"

- 1.6 Aerosol adhesives

- 1.7 Rubber compounds

- 1.8 Other varieties

- 2 How to choose a fabric adhesive: criteria worth considering

- 2.1 Manufacturing companies

- 2.2 Criterias of choice

- 3 Adhesives for fabric: types, applications and features of DIY manufacturing

- 3.1 Heat treated starch glue

- 3.2 Casein glue mixture

- 4 Techniques for using fabric adhesives in needlework

- 4.1 Bonding pieces of fabric together

- 4.2 Finishing the edges of fabric

Features of the manufacture and use of different types of fabric adhesives

The characteristics of adhesives can vary significantly. This determines their functionality and possible area of use. When choosing the appropriate option, it should be remembered that the substances produced by the industry differ not only in the components used in the production process, but also in the form.

Hot melt adhesives in powder and solid state

Hot melt adhesives are characterized by a high degree of adhesion. They form a secure seam. Environmentally friendly. Does not stain. Supplied in the form of a powder mixture, which is diluted before use to obtain a composition with the desired properties, or in the form of glue sticks. In this case, to glue the elements, you will need a special gun, with which the solid rods can be melted to apply glue to the surface.

Polyurethane-based waterproof adhesives

The base of the waterproof adhesive is polyurethane. The material is obtained by an artificial method as a result of the synthesis of organic polymers. Adhesives made on its basis are colorless. They have a sufficient level of strength characteristics. Do not create difficulties in the application process.

To initiate the curing process, special substances are introduced into the glue, which can be water and alcohol, acid and alkali solutions. Zinc oxide, titanium dioxide, Portland cement are used as fillers. The viscosity is adjusted with acetone. To increase the adhesion characteristics, a certain amount of synthetic resins is introduced.

The glue is prepared immediately before use, since, depending on the manufacturer, it can be applied within 0.5-3 hours after combining the substances. The components are mixed at a temperature of +20 ° C. It may take up to two days to cure if the composition hardens at room temperature. If the elements to be glued can be heated up to + 60-120 ° C, the waiting time is reduced to three hours.

Professional formulations with styrene butadiene

In sewing ateliers, styrene-butadiene-based compounds are most often used. They are characterized by increased elasticity. They resist the effects of ultraviolet radiation well, are not afraid of temperature fluctuations, and dry out quickly. They are very often used for decorating felt and leather.

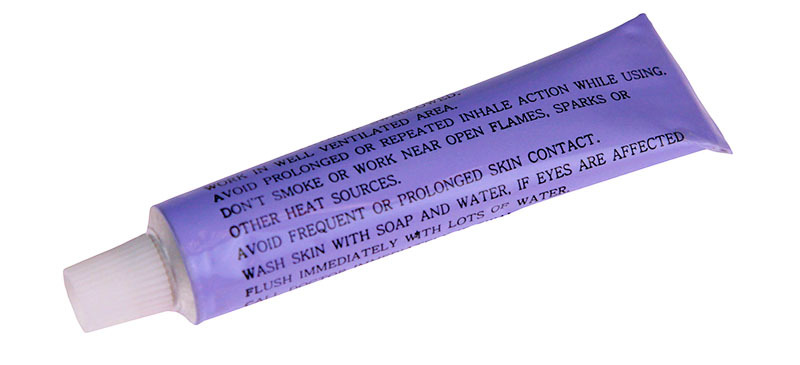

Universal adhesives in tubes

For home use, many acquire universal formulations, packaged in packages of various sizes. If a small amount of work is planned, you can pay attention to a tube weighing 125 g. If the composition inside is made on the basis of polyurethane, it can be used in the future when gluing elements from other materials.

For one-time work, a tube weighing 25 g is enough. A durable elastic seam can be formed with the all-purpose adhesive. The release form facilitates the process of applying and dispensing the glue.

Adhesive "liquid thread"

"Liquid thread" is produced transparent, and therefore does not leave characteristic spots on the surface. To connect the elements, the composition is applied in a thin uniform layer to the surfaces to be glued, and then, after waiting a few seconds, they are pressed against each other, applying some effort.

The composition of the specialized glue allows it to resist temperature fluctuations well, and is not afraid of the effects of moisture and chemicals. It is widely used in the design of corduroy, wool, cotton, linen.

Aerosol adhesives

For such adhesives, a special form of release is characteristic. They are supplied in cans that can be sprayed onto any size substrate. They resort to using aerosol glue if you need to fix the pattern, sew in a zipper, beautifully decorate the edge of the fabric or make a basting. Lack of contact with ambient air significantly increases the service life of the composition.

Inside the can, the adhesive is under pressure. The composition begins to spray after pressing the head. The composition is quickly and evenly distributed over the surface. At the same time, the required dosage is provided and it becomes possible to access hard-to-reach places.

There are many types of aerosol glue. Manufacturers offer:

- Temporary compositionsused for fixing decor not only on fabric, but also on paper or cardboard. Elements are fixed instantly. After detaching the previously glued parts, the base remains clean.

- Permanent lineups, allowing you to form a strong and reliable connection. With their help, not only fabric is glued, but also film, plastic, foil. Set quickly. Invisible on the surface.

In the following video, you can see the specifics of using aerosol formulations:

Rubber compounds

Rubber-based adhesives allow the elements to be reliably fixed relative to each other without leaving any stains. When using such an adhesive, a thin layer of the substance is applied to the surface and left to dry completely. Before joining the elements, the adhesive layer is lubricated with acetone. For a more reliable fixation, a weight is applied from above.

Other varieties

In addition to the listed types, PVA glue, or polyvinyl acetate, is widely used for gluing fabrics. It is used when joining materials of various types. Supplied in containers of different sizes. You can buy 50 g with a small amount of work, or you can buy a ̶ liter jar.

How to choose a fabric adhesive: criteria worth considering

To purchase a suitable adhesive composition, you need to know exactly what criteria deserve attention during the selection. The quality and cost of the glue largely depends on its functionality and the manufacturer's company.

Manufacturing companies

The cost of the adhesive composition depends on the trademark under which it is issued.

Products deserve attention:

- "Guterman". It can be used for processing dense fabrics, fixing embroidery elements. The absence of solvents in the composition does not create problems during the subsequent washing or dry cleaning.

- "Decola". The composition is quite thick and at the same time does not allow for dilution. This complicates the application process somewhat. It is widely used in the application of applications.

- Mod podge fabric. Allows you to form a beautiful coating, not only fixing decorative elements, but also protecting them from external influences.

- JAVANA. Forms a matte finish resulting from the thermal effect of the iron. Used when working with fine lace.

- UHU Textile. Waterproof. It can be used to decorate fabrics with different compositions. Withstands drying on batteries, ironing.

- "Second". Universal fast fixing compound.

Criterias of choice

When choosing an adhesive, you should consider the purpose of the purchase. If you need to qualitatively repair the place of a cut or rupture, you should use a universal or second-hand glue. It will quickly harden, it will be absorbed without excess, leaving no residue. In this case, you can not be afraid of damage to it during the washing process. To restore the integrity of outerwear or jeans, universal compounds are also suitable.

When choosing a suitable composition, you should pay attention to:

- The ability to process fabric.

- Safety of use.

- Resistance to mechanical stress. This will prevent creases, stretching and other damage to the finished product.

- Inertness of components to chemicals.

- Colour. Transparent formulations are preferred.

- Resistant to temperature fluctuations.

- The possibility of forming an elastic seam.

Adhesives for fabric: types, applications and features of DIY manufacturing

If there is no suitable option among the compositions offered by industrial enterprises, you can make glue yourself. Its composition will largely depend on the destination.

Heat treated starch glue

To prepare such an adhesive composition, you need to take starch and water.

The manufacturing process is as follows:

- The starch is poured into a large-diameter enamel container and placed in an oven preheated to +160 ° C. Here he should be for two hours.

- Boil water. Its volume should correspond to the volume of starch taken.

- Heat-treated starch is very carefully poured into boiling water in a thin stream.

- The mixture is thoroughly mixed, ensuring complete dissolution of the starch.

Attention! The composition quickly hardens, and therefore you should start using it immediately after preparation.

Casein glue mixture

To prepare a casein glue mixture, you will need 2 parts of casein and 1 part of water. Water is poured into the composition in a thin stream to prevent the formation of lumps. In this case, the entire mixture must be thoroughly mixed, achieving homogeneity.

Attention! If the mixture dries up, its further use becomes impossible.

Casein is made at home from low-fat cottage cheese or milk. The procedure is quite complicated. Most often, powder casein is used to prepare the adhesive composition.

Techniques for using fabric adhesives in needlework

The procedure for using fabric glue in needlework depends on the operation being performed. In order not to be mistaken and not to damage the matter, it is worth initially getting acquainted with the technique of performing work. It will be slightly different when gluing pieces of fabric together and processing the edge. Therefore, you need to know how to glue this or that defect or decorate the canvas.

Bonding pieces of fabric together

The need to glue pieces of fabric together can arise in a variety of situations. Most often, in this way, clothing is repaired or an applique is fixed. In the latter case, the work is performed in the sequence indicated in the table.

| Illustration | Procedure |

| The elements to be joined are cut to size. Considering that they will stick together by means of an adhesive, all excess is cut off before starting work. |

| An adhesive is applied to one of the parts to be joined. It is evenly distributed over the surface. |

| The pieces to be glued are placed on top of each other and pressed carefully. For a secure fixation, you can put a weight that will ensure an even distribution of the load. |

Advice! When making repairs, use a cushioning material to reinforce the joint.

Finishing the edges of fabric

Edging can be done in different ways. In one case, it is enough to simply coat the edge with adhesive. In the other ̶, the material is tucked in. To achieve the formation of a beautiful edge, first it is carefully ironed, and then the bent part is fixed.

Share in the comments what kind of fabric glue you have already used, why you made a choice in favor of it, and whether you need it in needlework.