The desire to bend a sheet of metal into the required shape sometimes baffles the home craftsman. If it is a small item, you can use a hammer, pliers, and vise. But what if the size of the sheet is impressive. In this case, you will have to seek help from specialists, or... The author of the YouTube channel offers his solution to this issue Dmitriy, which explains how you can make a full-fledged sheet bending machine in a garage or a small workshop.

Read in the article

- 1 What material needs to be prepared for the manufacture of a listogib

- 2 Preparation of material for work, drawings, adjustment

- 3 Preparation of grooves for hinge hinges

- 4 Installing the clamp rails

- 5 Manufacturing and installation of the clamping element of the bending machine

- 6 Minor revision of the clamp

- 7 Refinement of the bending machine, manufacturing and installation of the handle of the movable platform

- 8 First tests: checking the bending machine for performance

- 9 Bending of what thickness of metal is possible for such a device

- 10 What parts can be made using a listogib

- 11 Finally

What material needs to be prepared for the manufacture of a listogib

The basis for such a device will be a steel channel and corners. We will not dwell on their sizes due to the fact that here everyone will decide this issue depending on the thickness of the metal planned for processing. Naturally, the thicker the sheet is, the more powerful parts will be required to make the device.

As for the tool, there is nothing new here, everything that is required when working with steel structures, namely:

- angle grinder (grinder);

- welding machine;

- a hammer.

Preparation of material for work, drawings, adjustment

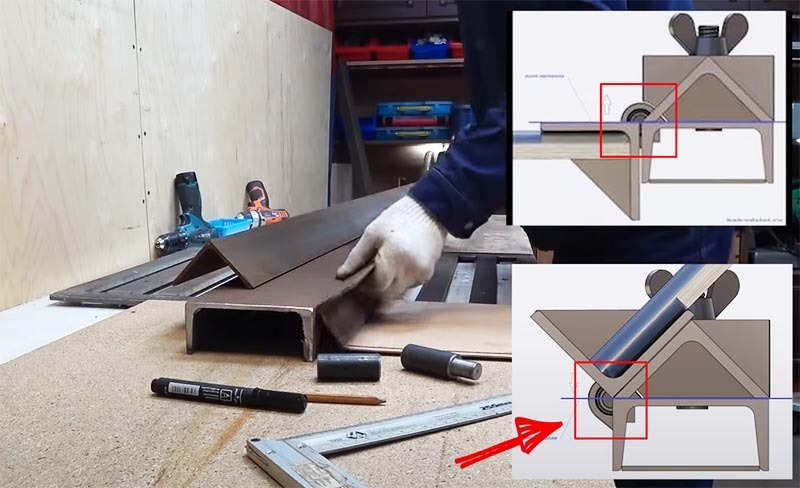

First you need to imagine how the bending machine should look like and what nodes it will consist of. The basis, of course, will be a massive channel. The element that will be responsible for the bending will be the steel corner. However, in order for it to move in the desired plane, it is necessary to correctly position the hinges. They cut into the channel and the corner, which allows these elements to be located in the same parallel. How it should look can be understood from the drawings, which are presented in the photo below.

Preparation of grooves for hinge hinges

Having noted the future location of the hinges, recesses need to be cut out in the channel and corner. This work is done using a grinder with a cutting disc. After the grooves are ready, they are checked for size and depth. If everything is in order, they can be grabbed by welding. It is not worth boiling the seam right away, you may have to fix something in the process.

Installing the clamp rails

In order for the processed sheet of metal not to "float" during bending, it is necessary to think over a clamp for it. To equip it, studs must be installed on both sides of the channel. It is not worth welding them, because over time they will have to be changed. It is better to drill through the channel and fix the studs with the locknuts.

Manufacturing and installation of the clamping element of the bending machine

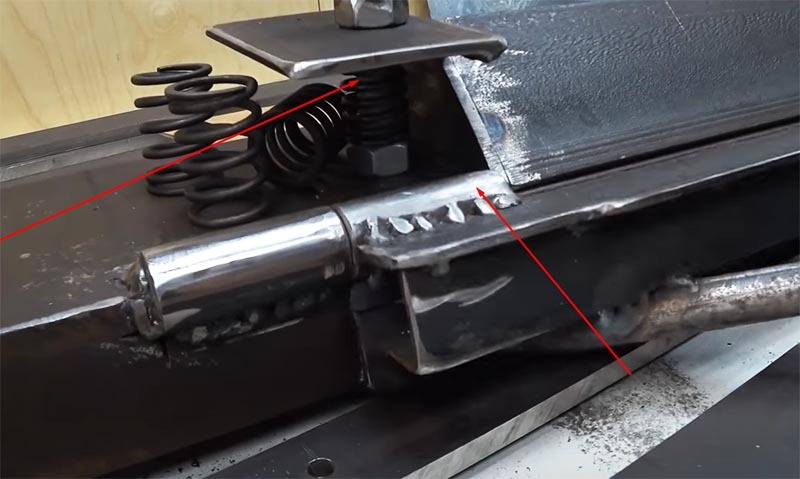

The clamp is made from the same angle as the movable working platform of the bending machine. After the corner is cut to size, small steel platforms with holes need to be welded on both sides of it. It remains to put springs on the studs (valve springs from any internal combustion engine of a passenger car are suitable), which will slightly raise the clamp, and then set the corner in place.

Minor revision of the clamp

In order to use the clamping mechanism, it is necessary to weld a couple of nuts to the T-pieces of the half-inch pipe. It is with the help of such knobs that the metal sheet will be fixed on the machine.

Refinement of the bending machine, manufacturing and installation of the handle of the movable platform

In order for the bending machine to be used, a handle should be welded to the movable corner. Its shape depends on the preferences of the master and can have one, two or three crossbars. For its more reliable fixation in the center of the corner, you need to weld the profile pipe. Now the work on the manufacture of the bending machine can be considered completely completed, it's time to start checking.

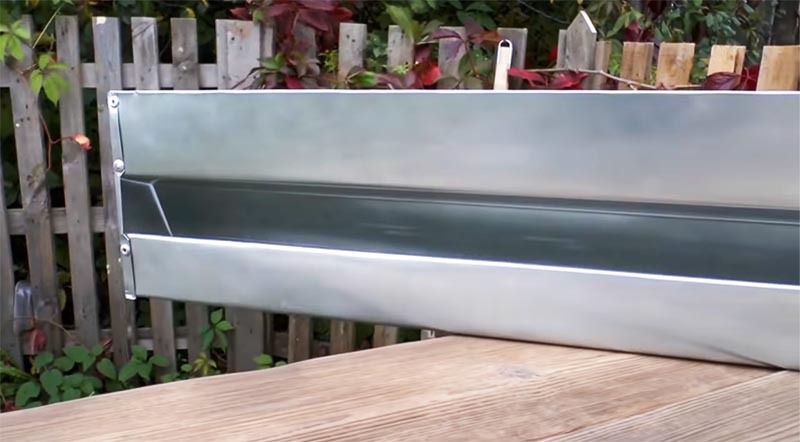

First tests: checking the bending machine for performance

Any unnecessary sheet material can be used for verification. First, the clamping bar is loosened, while the springs located on the hairpins squeeze the corner up. The sheet metal is slipped under the bar to the required distance. Further, with the help of cranks, the corner is lowered, pressing the material to the main platform (channel). It remains to raise the movable working platform by the handle, giving the metal bend the desired angle.

Bending of what thickness of metal is possible for such a device

If we talk about the use of such a device in the garage, then there are practically no restrictions on thickness. It is unlikely that the master will need to bend a sheet that is a centimeter thick. Well, at the household level, such a listogib copes with rather thick metal sheets without visible problems.

What parts can be made using a listogib

There are no restrictions here either. Speaking in detail, such a listogib even allows you to make a profiled sheet from an ordinary one. It is also possible to manufacture various containers, boxes and similar items.

Finally

It is clear that such a listogib may not be useful to everyone in the garage. However, even if you use it only a few times, the manufacture of such a device will definitely justify itself. By the same time, such a homemade product will not take much. If you fully understand the essence of all the work, then you can spend no more than two hours on the manufacture of a listogib. Let's add here the cheapness of the materials required for homemade products, and we get a functional device for a penny at the output, which allows you to bend metal at different angles.

We hope that the information presented today will be useful not only for novice home craftsmen, but also for those who have been engaged in such work for several years. The HouseChief editors will definitely answer all your questions on the topic, if any. Just summarize them in the discussions below. There you can comment on what you read, share your opinion on how such a homemade product can be useful in a garage or home workshop.

If the article was interesting to you, do not forget to rate what you read. Your opinion is very important to us.

Take care of yourself, your loved ones and be healthy!