Plumbing was invented so long ago that we can no longer imagine our existence without it, as without air or electricity. But few people imagine how complex this system is, consisting of pipes, various connectors, splitters and locking devices. We will talk about the latter today. HouseChief experts will tell you what a type of shut-off valve such as a ball coupling valve is, tell about its purpose and types.

Read in the article

- 1 What is a coupling ball valve for?

- 2 The device and principle of operation of the ball valve

- 3 Varieties of ball locking mechanisms

- 3.1 Materials used for ball valves

- 3.2 Structural differences of the case

- 3.3 Capabilities of the gate assembly

- 3.4 Method of connection to the pipeline

- 3.5 Ball valve flow capacity

- 3.6 Control design

- 4 Advantages and disadvantages of ball valves

- 5 Leading manufacturers of valves

- 5.1 VALTEC (Italy)

- 5.2 Bugatti (Italy)

- 5.3 Stout (Spain)

- 5.4 GEKON (Italy, with production in Russia)

- 5.5 RM (China)

- 6 The best ball valve models

- 6.1 Ball valve VALTEC VTp.742.0.02004 combined, brass, with a union nut for household appliances

- 6.2 Ball valve Bugatti New Jersey 922 coupling (BP / BP), brass

- 6.3 Ball valve STOUT SVB-0001-000025 coupling (BP / BP), brass

- 6.4 Ball valve GEKON GK 554 12 coupling (ВР / НР), brass

- 6.5 Ball valve with American half-grip ¾ "bow, brass RM MP-U IS.080924

- 7 How to choose the right quality ball valve

What is a coupling ball valve for?

A coupling ball valve is a type of pipeline shut-off device. Its shutter has a spherical shape, and the body is made in the form of a coupling, which is connected to engineering systems by means of a threaded connection. Ball couplings are designed to quickly shut off or open the flow of the working medium in the pipeline. Due to their ease of installation and high tightness, they are widely used in domestic water and gas supply networks, as well as heating systems. To operate the crane, it is enough to turn the handle or lever, whereas in old traditional devices, this required turning the valve several times.

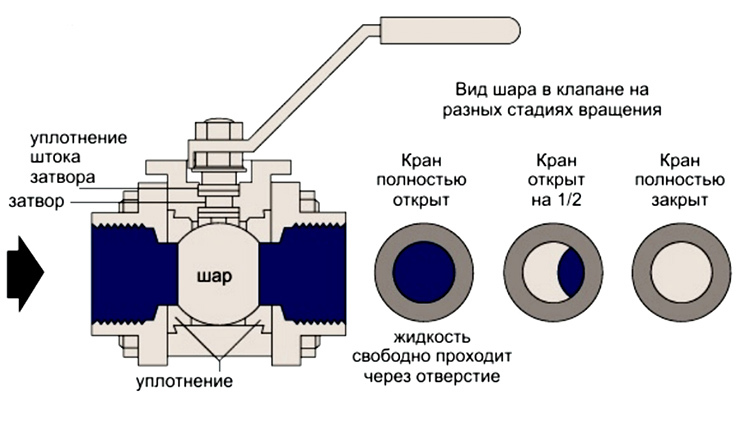

The device and principle of operation of the ball valve

The ball valve has a fairly simple design. The locking device consists of:

- Body, which is a straight or angular coupling.

- Locking and regulating mechanism in the form of a hollow sphere with a through hole. In fact, this is the main unit and "highlight" of the ball valve.

- The rod that drives the sphere.

- Valve or ball valve control lever.

- Saddles and seals to ensure tightness of the connection.

Coupling locking devices are characterized by the presence of two or more connecting pipes, as in a standard fitting. A distinctive feature of the ball valve is a hollow sphere with a through hole, which allows you to regulate the flow of the working medium in the pipeline. When the hole of the ball and the outlet of the coupling coincide, the liquid or gas flows freely through the shut-off valves. To reduce or completely stop the flow, you just need to turn the lever or valve and the sphere will turn to the outlet with the blind side, and the flow of the working medium will be stopped.

Varieties of ball locking mechanisms

This type of shut-off device has several varieties, which differ in design, throughput, flow regulation, structure of the control unit and material of manufacture. Below we will look at these issues.

Materials used for ball valves

For the manufacture of valves, a variety of metals and their alloys can be used:

- steel;

- brass;

- bronze;

- cast iron;

- chromium;

- zinc-aluminum alloy;

- polypropylene.

The use of this or that material is due to the purpose of the part and the features of operation. The most commonly used metal in the production of ball valves is brass, which is due to its high anti-corrosion and strength characteristics.

Structural differences of the case

According to the structure of the body, shut-off valves with a ball valve are subdivided into:

- Monoblock - cast all-metal or polypropylene construction.

- Two-piece. The body is a structure of two parts: the main one (all-metal or forged with one branch pipe), where the working unit is located, and the small one (the second connecting branch pipe).

- Three-part, consisting of a main central element and two connecting pipes.

Capabilities of the gate assembly

According to the capabilities of the shutter device, ball valves are divided into:

- locking - have only two positions: open and closed;

- regulating - able to smoothly change the force of the pressure of the working environment;

- three-way - the body is a tee, the holes in the metal sphere are made in such a way so that you can redirect fluid to different branches of the pipeline or connect the streams of two workers together wednesday

Method of connection to the pipeline

Ball valves also differ in the way they are connected to communications:

- Threaded. The valve with an external thread is screwed into the pipe or screwed onto it (internal threaded connection).

- Crimp. The connections are threaded, but a crimp nut is required to connect.

Ball valve flow capacity

By throughput, the following types of coupling ball valves are distinguished:

- full bore. The diameter of the through hole in the sphere of the gate assembly is the same or slightly less (1-10%) of the inner section of the pipe. This makes it possible to skip the working environment in full;

- standard bore. The hole in the ball of the working unit is smaller than the inner diameter of the branch pipe, which reduces the throughput of the valve.

Control design

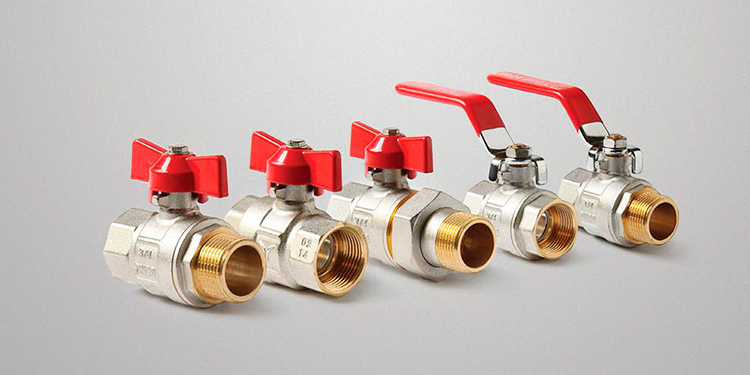

Ball coupling valves by control type can be:

- Valve. Equipped with a butterfly knob.

- Lever.

Advantages and disadvantages of ball valves

This type of valves is widely used in the construction of industrial and domestic water supply, heating and gas systems. This is due to the large number of advantages of ball valves of any type:

- long service life (at least 5 years and 20,000 cycles in budget models and more than 10-20 years in expensive and better quality products);

- small weight and dimensions (household models);

- a large number of varieties and a wide price range;

- variability of the location of the control lever or handle;

- tightness and reliability of blocking the flow of the working medium;

- reliability of the design, which is achieved due to the minimum number of parts;

- ease of installation, dismantling and ease of repair;

- ease of operation and maintenance;

- ease of control and adjustment.

Despite such a number of advantages, ball valves also have disadvantages that cannot be discounted:

- small range of standard sizes. This type of valves is installed in pipelines with an inner diameter of 15-40 mm;

- narrow temperature range at which the operation of ball valves is allowed;

- poor tolerance of probable water hammer;

- cannot be used in high pressure pipelines;

- with prolonged inactivity, sticking of the working sphere is likely. To avoid this, the tap must be opened and closed regularly.

Leading manufacturers of valves

The modern market for sanitary ware and accessories is represented by a large number of manufacturers, which greatly complicates the selection of the required products. Therefore, we have compiled a rating in different categories.

VALTEC (Italy)

Bugatti (Italy)

Stout (Spain)

GEKON (Italy, with production in Russia)

RM (China)

The best ball valve models

After we have learned about the valves manufacturers, let's get to know the most popular ball valve models from well-known brands.

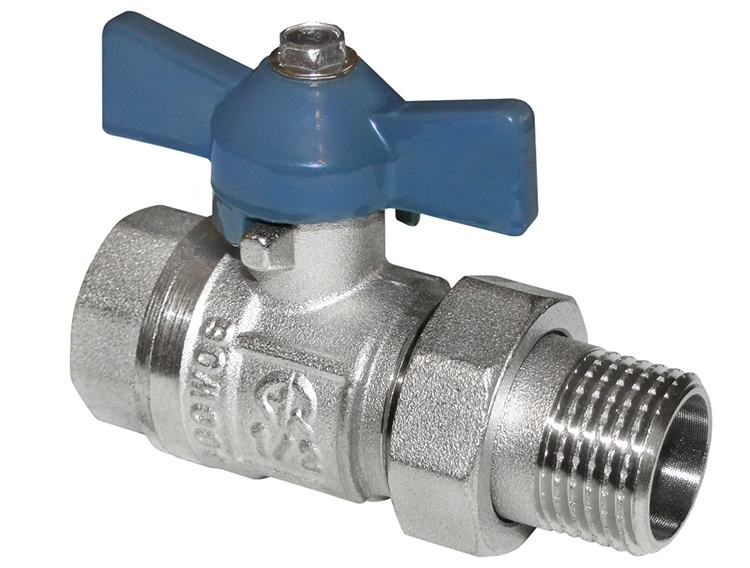

Ball valve VALTEC VTp.742.0.02004 combined, brass, with a union nut for household appliances

Ball valve VALTEC VTp.742.0.02004 combined, brass, with a union nut for household appliances

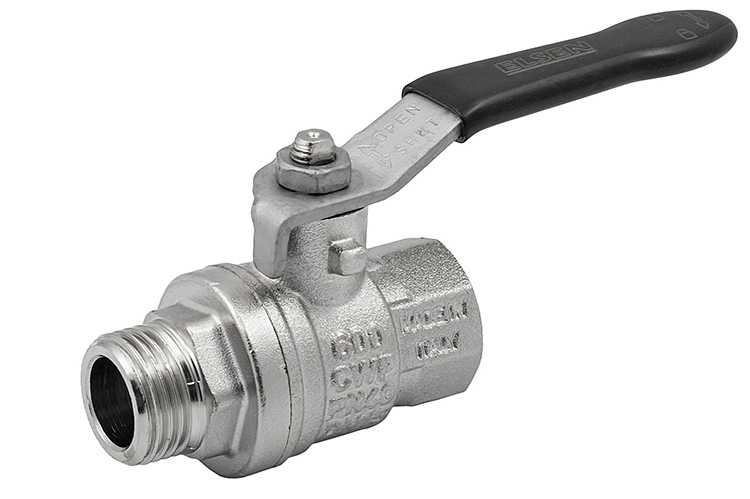

Ball valve Bugatti New Jersey 922 coupling (BP / BP), brass

Ball valve Bugatti New Jersey 922 coupling (BP / BP), brass

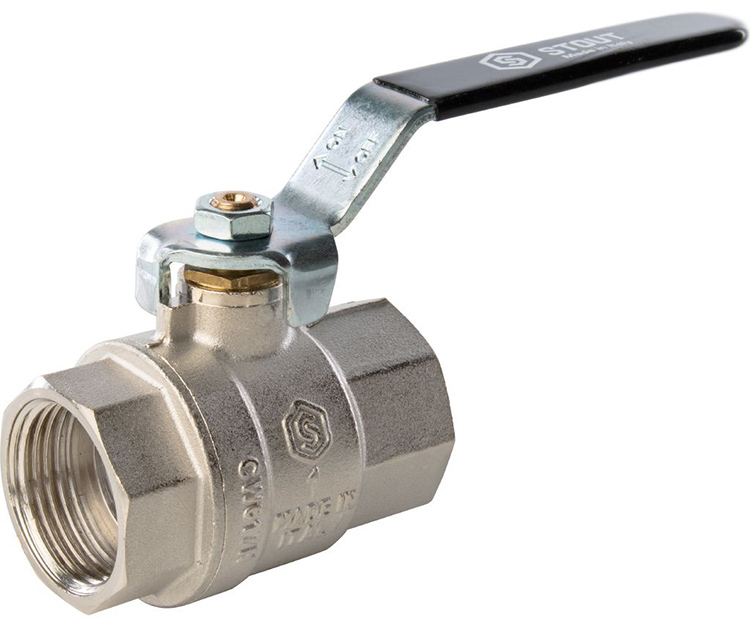

Ball valve STOUT SVB-0001-000025 coupling (BP / BP), brass

Ball valve STOUT SVB-0001-000025 coupling (BP / BP), brass

Ball valve GEKON GK 554 12 coupling (ВР / НР), brass

Ball valve GEKON GK 554 12 coupling (ВР / НР), brass

Ball valve with American half-grip ¾ "bow, brass RM MP-U IS.080924

Ball valve with American half-grip ¾ "bow, brass RM MP-U IS.080924

Ball valve with American half-grip ¾ "bow, brass RM MP-U IS.080924

How to choose the right quality ball valve

When buying a ball valve, you need to take into account a few simple recommendations that will help in choosing high-quality and appropriate shut-off valves. Since this product is intended for work at elevated pressure, it must necessarily have quality certificates. The material of the body and the ball valve must also be suitable for the process fluid that will flow through the valve.

The diameter of the opening of the shutter mechanism must be equal to the cross-section of the main pipes. It is also necessary to check that all parts fit snugly to the landing sites, do not play, and the handle turns without great effort. The metal of the case must be free of rust, streaks or sagging.

It is necessary that the working pressure of the shut-off valves in value exceeds the main one. The ball valve must also be able to withstand water hammer. For the system to work smoothly, purchase valves in specialized stores, and not in construction markets.

In conclusion, we suggest watching a video on how to choose the best ball valve for your home.

Also, it will not be superfluous to get acquainted with the video, which tells and shows how to independently replace the shut-off valves.